Radial selenium nanotube and preparation method thereof

A selenium nano, radial technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of single selenium nanotube method, complex synthesis process, unfriendly environment, etc. Friendly, cheap and easy to obtain raw materials, simple process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A radial selenium nanotube, its preparation method comprises the steps:

[0027] 1) Preparation of amorphous selenium precursor: Dissolve 2 g of polyvinylpyrrolidone (PVP) with a molecular weight of 55,000 in 100 ml of deionized water, and after the dispersion is uniform, add 2 g of selenous acid and stir magnetically for 30 minutes to obtain a colorless and transparent solution. Slowly add 5g of ascorbic acid, react for 3h, the transparent solution gradually turns brick red, and then centrifuge and wash to obtain amorphous selenium;

[0028] 2) Preparation of radial selenium nanotubes: Disperse 200 mg of amorphous selenium obtained in step 1) in 100 ml of absolute ethanol, let stand for 8 hours to obtain a gray solution, and sequentially wash with deionized water and absolute ethanol to obtain the final product.

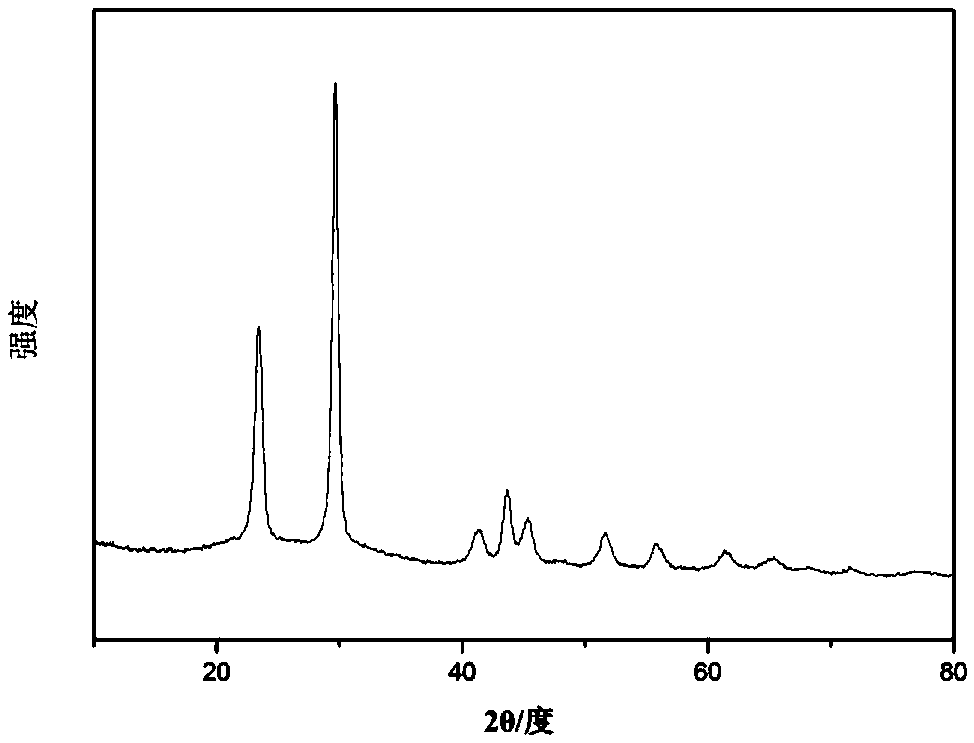

[0029] Carry out powder X-ray diffraction analysis to step 1) gained precursor amorphous selenium, the results are shown in figure 1 , the diffraction peaks...

Embodiment 2

[0032] A kind of radial selenium nanotube, its preparation method comprises the steps:

[0033] 1) Preparation of amorphous selenium precursor: Dissolve 3 g of polyvinylpyrrolidone (PVP) with a molecular weight of 40,000 in 100 ml of deionized water, add 4 g of selenous acid after the dispersion is uniform, and stir magnetically for 30 minutes to obtain a colorless and transparent solution. Slowly add 3g of ascorbic acid, the transparent solution gradually turns into brick red, after reacting for 5 hours, the resulting brick red liquid is centrifuged and washed to obtain amorphous selenium;

[0034] 2) Preparation of radial selenium nanotubes: Disperse 500 mg of amorphous selenium obtained in step 1) in 100 ml of absolute ethanol, let stand for 12 hours to obtain a gray solution, and sequentially wash with deionized water and absolute ethanol to obtain the final product.

Embodiment 3

[0036] A kind of radial selenium nanotube, its preparation method comprises the steps:

[0037] 1) Preparation of amorphous selenium precursor: Dissolve 4 g of polyvinylpyrrolidone (PVP) with a molecular weight of 55,000 in 100 ml of deionized water, add 2 g of selenous acid after the dispersion is uniform, and stir magnetically for 30 minutes to obtain a colorless and transparent solution. Add 5g of ascorbic acid, the transparent solution gradually turns into brick red, after reacting for 3 hours, the resulting brick red liquid is centrifuged and washed to obtain amorphous selenium;

[0038] 2) Preparation of radial selenium nanotubes: Disperse 300 mg of amorphous selenium obtained in step 1) in 100 ml of absolute ethanol, let stand for 10 hours to obtain a gray solution, and sequentially wash with deionized water and absolute ethanol to obtain the final product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com