A space rope net closing device

A closing device and rope net technology, applied in the field of space applications, can solve the problems of increasing the complexity of the circuit, the rotation of the closing device, and increasing the risk of failure, and achieve the effects of saving complexity, avoiding failure problems, and flexible design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

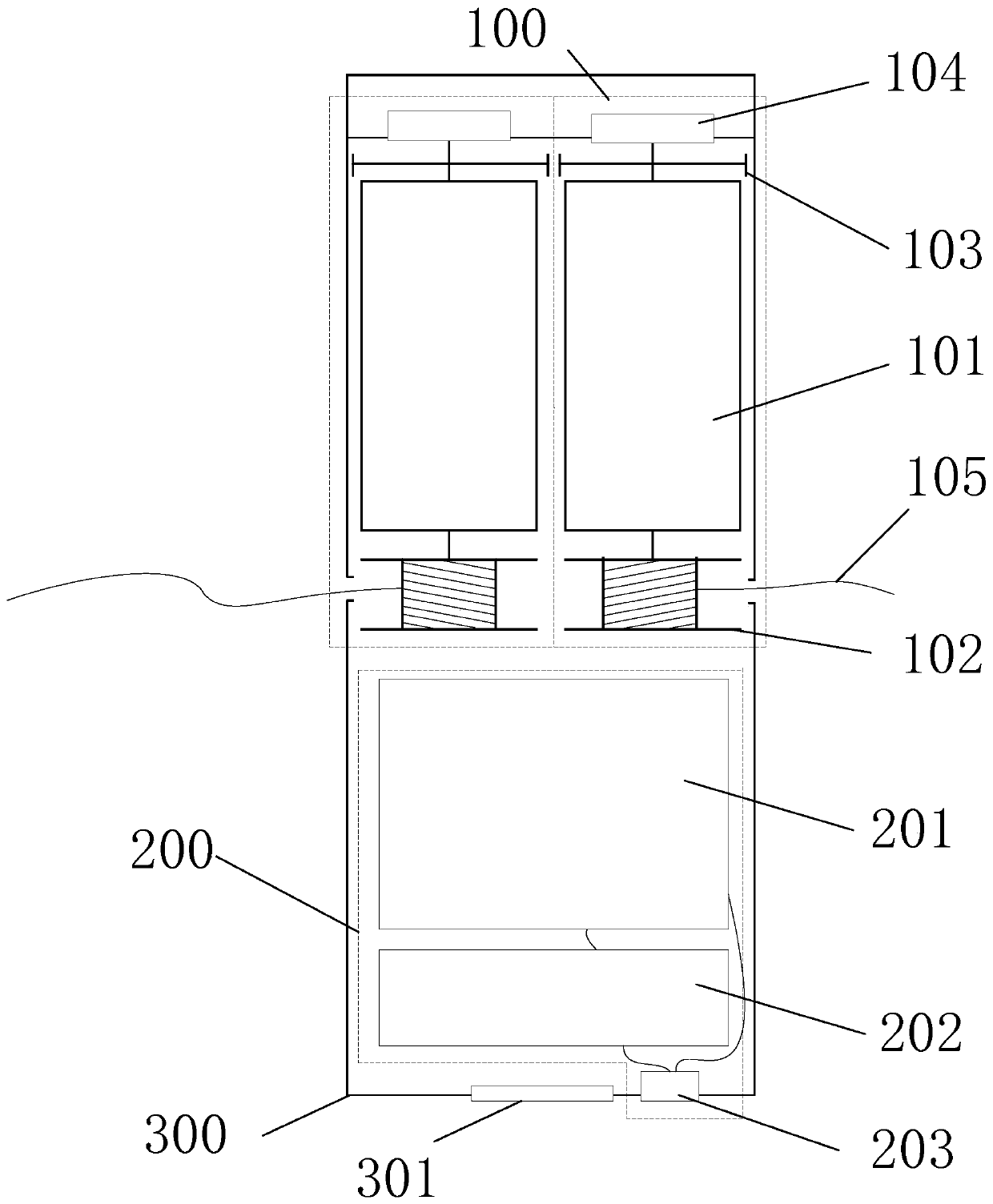

[0033] see figure 1 , a space rope net closing device, comprising a take-up unit, a power supply control unit and a structural housing, wherein the take-up unit includes a first motor and a second motor, the first motor includes a first output shaft, and the first output shaft The first winding wheel, the first transmission gear and the first ratchet mechanism are arranged on the top; the second motor includes a second output shaft, and the second winding wheel, the second transmission gear and the second ratchet are arranged on the second output shaft mechanism, the position of the second transmission gear matches the position of the first transmission gear; the first motor and the second motor are fixed in parallel in the axial direction, the second transmission gear and the first transmission gear are both on the same end side of the transmission shaft, and the two transmission gears mesh Transmission connection, when the first motor and the second motor rotate, the two gro...

Embodiment 2

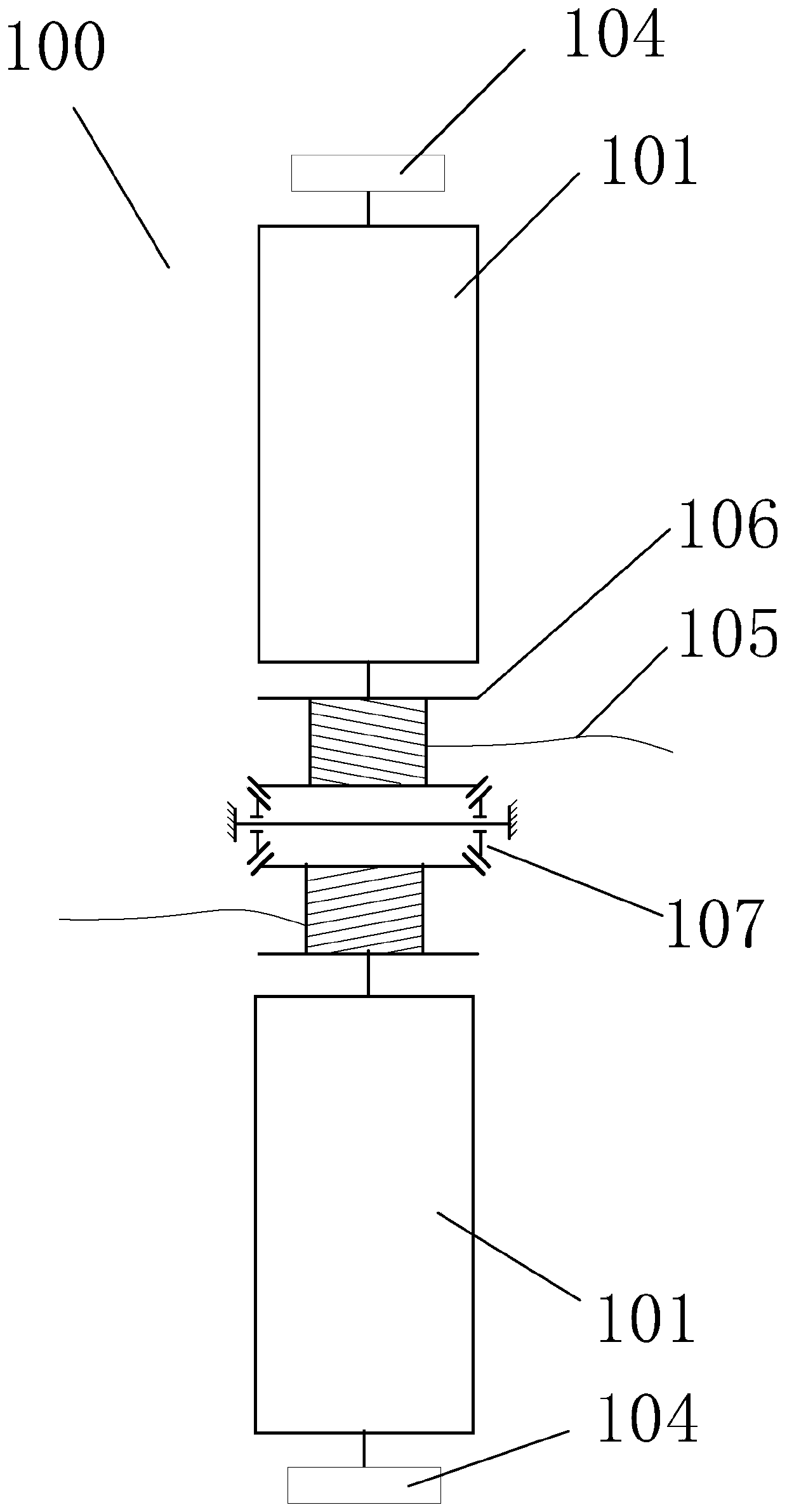

[0044] see figure 2 , this figure is a structural schematic diagram of another embodiment of the present invention, in this structure, two take-up units are fixedly arranged inside the structural housing in an axial series manner, and a reel with gears 106 is used in this embodiment , the geared reel 106 realizes the same-speed rotation between the two motors 101 through two idler gears 107 in the form of bevel gears. The embodiment of the take-up unit 100 can also realize the constant speed rotation of the two motors 101 and the transmission. When the wire is taken up, the rotation directions of the two motors 101 (referring to the motor 101 body) are the same, that is, forward rotation or reverse rotation at the same time.

[0045]This structure can save the space occupied in the width direction, and different structural arrangements can be selected according to the structural characteristics of the aircraft. The closing device provided by the present invention, by introd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com