Combined printing machine

A combined printing press and offset printing technology, applied in printing presses, rotary presses, printing and other directions, can solve the problems of high printing cost and low positioning accuracy, and achieve the effect of accurate overprinting and low rejection rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention is further explained in detail below in conjunction with the accompanying drawings.

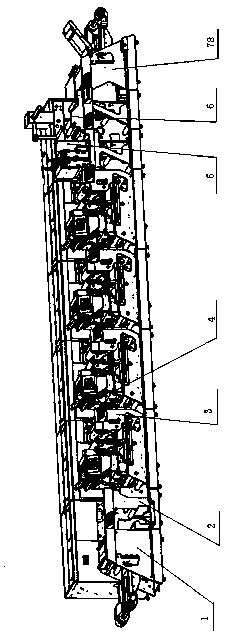

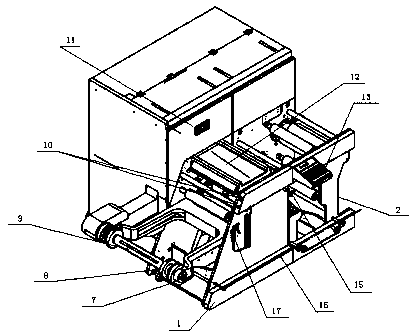

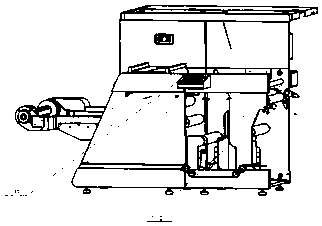

[0032] Such as figure 1 As shown, a combination printing machine according to the present invention includes an unwinding unit 1, a paper feeding unit 2, an offset printing unit 3, an offset printing ink unit 4, a die-cutting unit 5, a waste discharge unit 6, and a winding unit 78. Unwinding unit 1, paper feeding unit 2, offset printing unit 3, offset printing ink unit 4, die-cutting unit 5, waste discharge unit 6, winding unit 78 are arranged sequentially in the paper conveying direction, and paper feeding unit is arranged at the rear of unwinding unit 1 2. The paper is transported to the offset printing unit 3 with the paper feeding unit 2. After the offset printing unit 3 is installed on the paper feeding unit 2, several offset printing units 3 are continuously set on the printing machine. Linear guide rails are set at both ends of the offset printing unit 3. O...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com