Manufacturing method of single-side flamed surface composite stone board

A manufacturing method and technology for stone slabs, applied in chemical instruments and methods, lamination devices, lamination auxiliary operations, etc., can solve the problems of reducing the structural strength of the finished product, affecting the curing effect of the finished product, complex processing technology, etc., and simplifying the manufacturing process. , Avoid overheating in local areas and improve the effect of production quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The technical scheme of the present invention is further described below, but the scope of protection is not limited to the description;

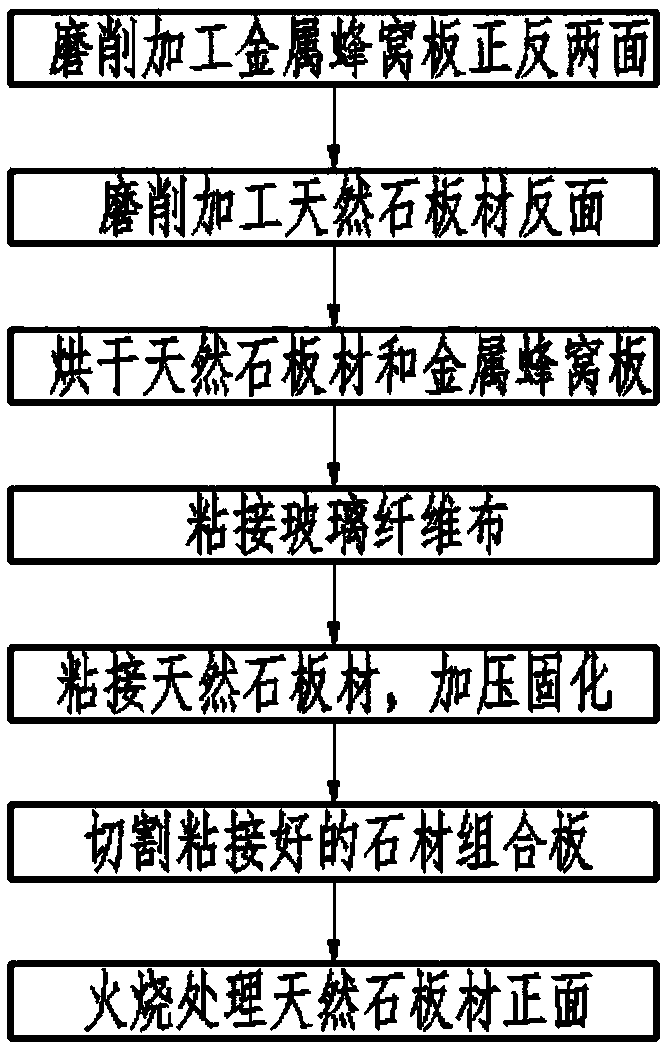

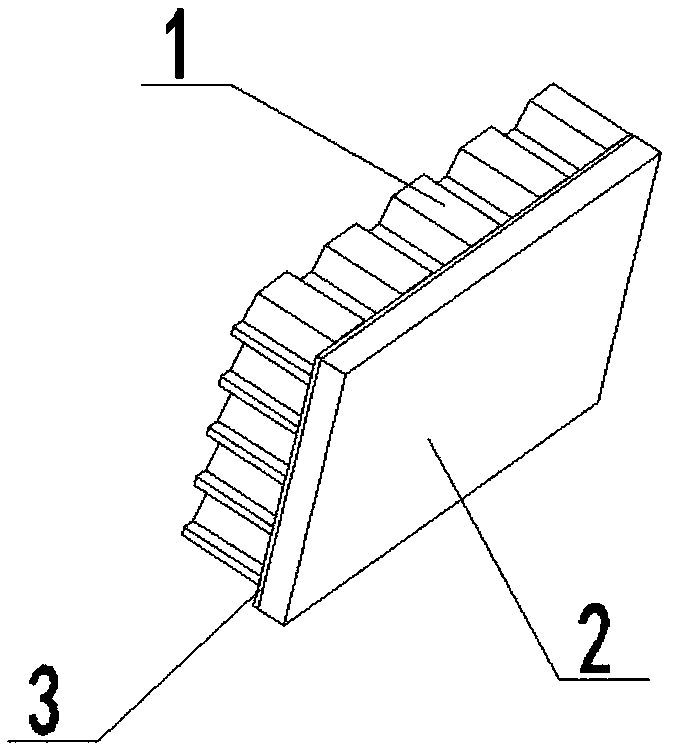

[0032] The invention provides a method for manufacturing a composite stone board with a single side fire surface, such as figure 1 , figure 2 , image 3 shown, including the following steps:

[0033] Step 1: Take the metal honeycomb panel 1, and grind the front and back sides of the metal honeycomb panel 1, so that the surface roughness of the front and back sides of the metal honeycomb panel 1 reaches below 6.3 microns; further, the metal honeycomb panel 1 is made of 7075 Made of hard aluminum alloy.

[0034] Step 2: Take the natural stone slab 2, and grind the reverse side of the natural stone slab 2, so that the surface roughness of the natural stone slab 2 reverse surface reaches below 12.5 microns; further, the process parameters for grinding the natural stone slab 2 reverse side by using a grinder are: The grinding machine...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com