Production controlling method of wide-width and thin-gauge super stainless steel plate or coil of single frame steckel mill

A production control method and technology for furnace coil rolling mills, which are applied in rolling mill control devices, metal rolling, temperature control, etc., can solve the problem that the thickness and width of special alloy plates cannot meet the needs of the market, and achieve rich product diversity and reduce The effect of removing scales and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

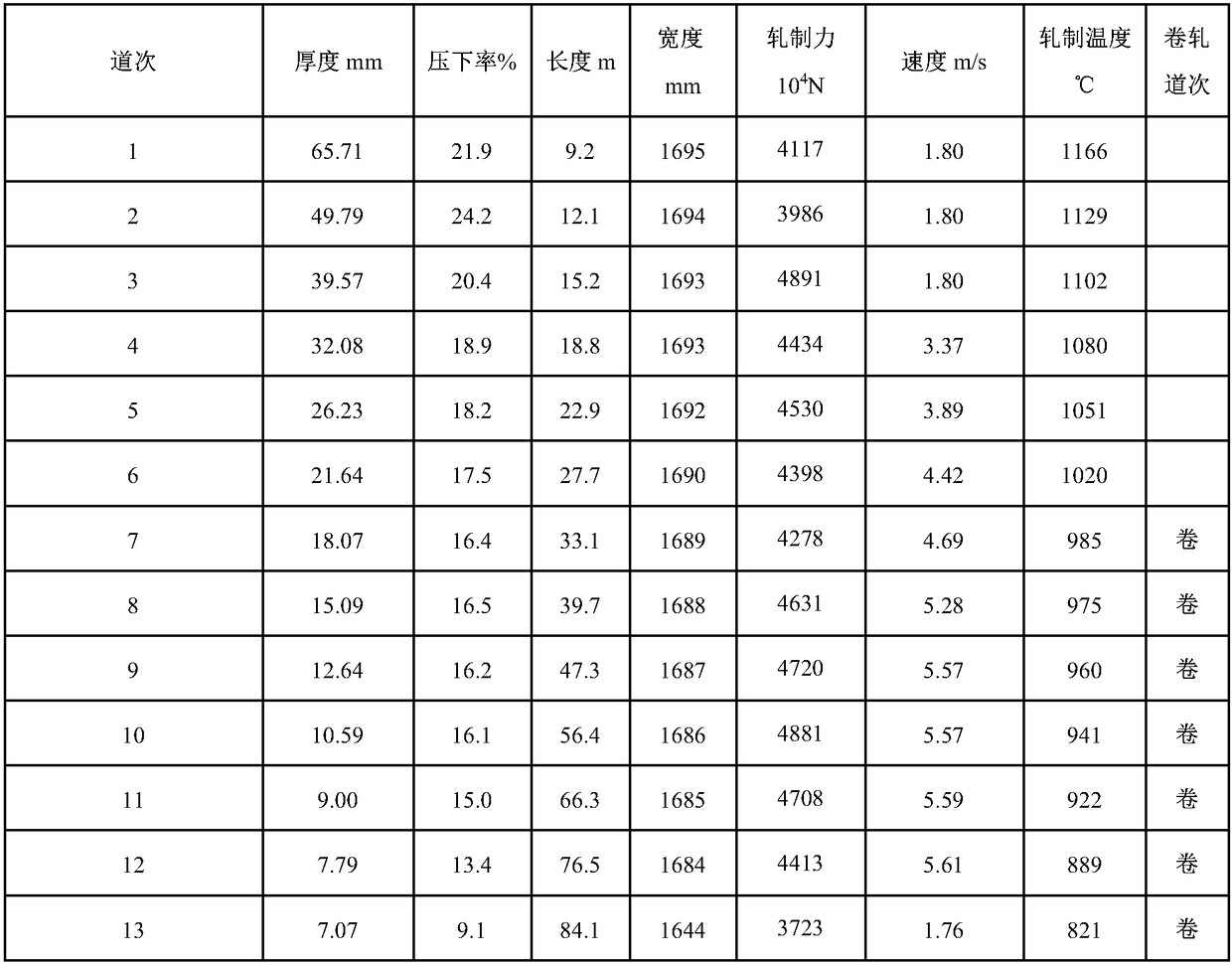

Embodiment 1

[0026] 1. Production plan:

[0027] To adapt to different raw material sources and carry out different material type design, optimize the steel loading plan for heating furnace according to the characteristics of super stainless steel grades, determine the transition plate with similar width and matching thickness, confirm the plate shape and surface in advance, and produce super stainless steel according to the easy-to-use Strictly limit the production sequence from narrow to wide. For non-standard size blanks, the method of manual positioning and loading of steel is adopted to ensure accurate cloth position and stable loading of steel.

[0028] 2# Heating Furnace Single Furnace: High temperature heating roll stage → coil rolling 2 row transition thickness 8-10mm (within width 2200mm, high strength 960, etc. priority) → wide and thin S32053 alloy coil

[0029] 2. Requirements for the use of blanks:

[0030] Incoming material confirmation and targeted adjustment, aiming at t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com