Grain drying and screening integrated device

A grain drying and screening technology, which is applied in the agricultural field, can solve the problems of poor drying effect, slow screening speed, and inability to realize the separation of grains of various specifications, and achieves the effects of speeding up the speed, improving the flow rate and saving the screening time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical scheme of this patent is described in further detail below in conjunction with specific embodiments

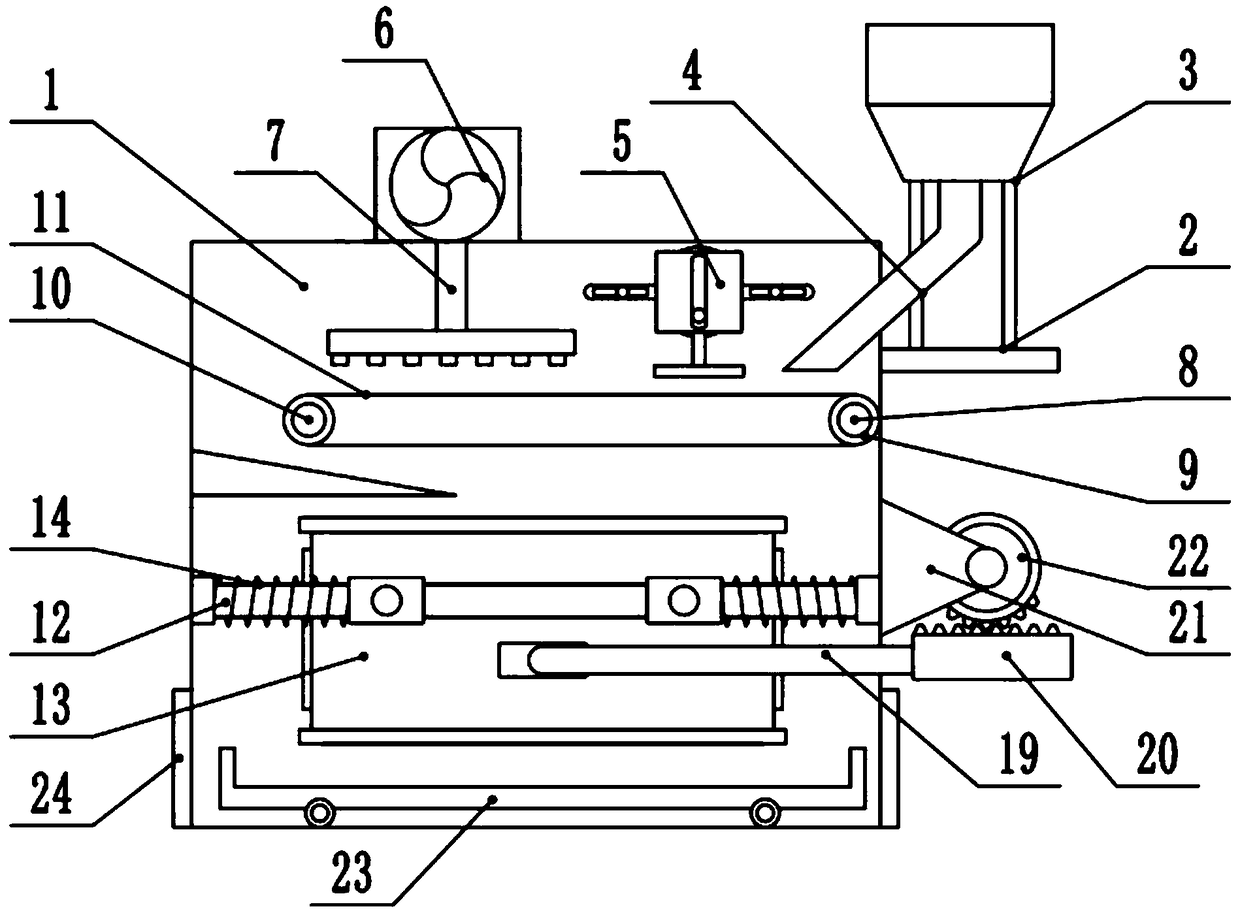

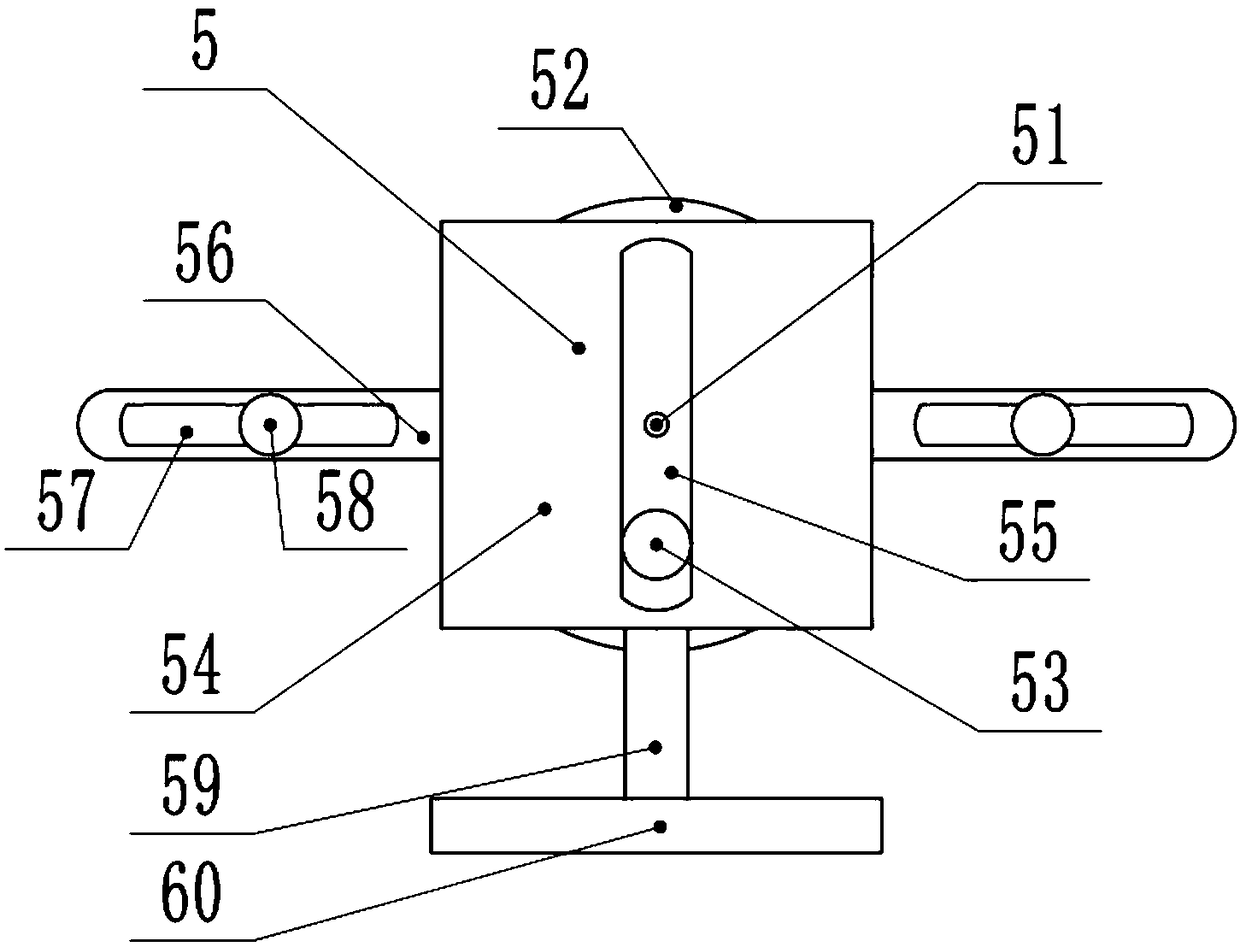

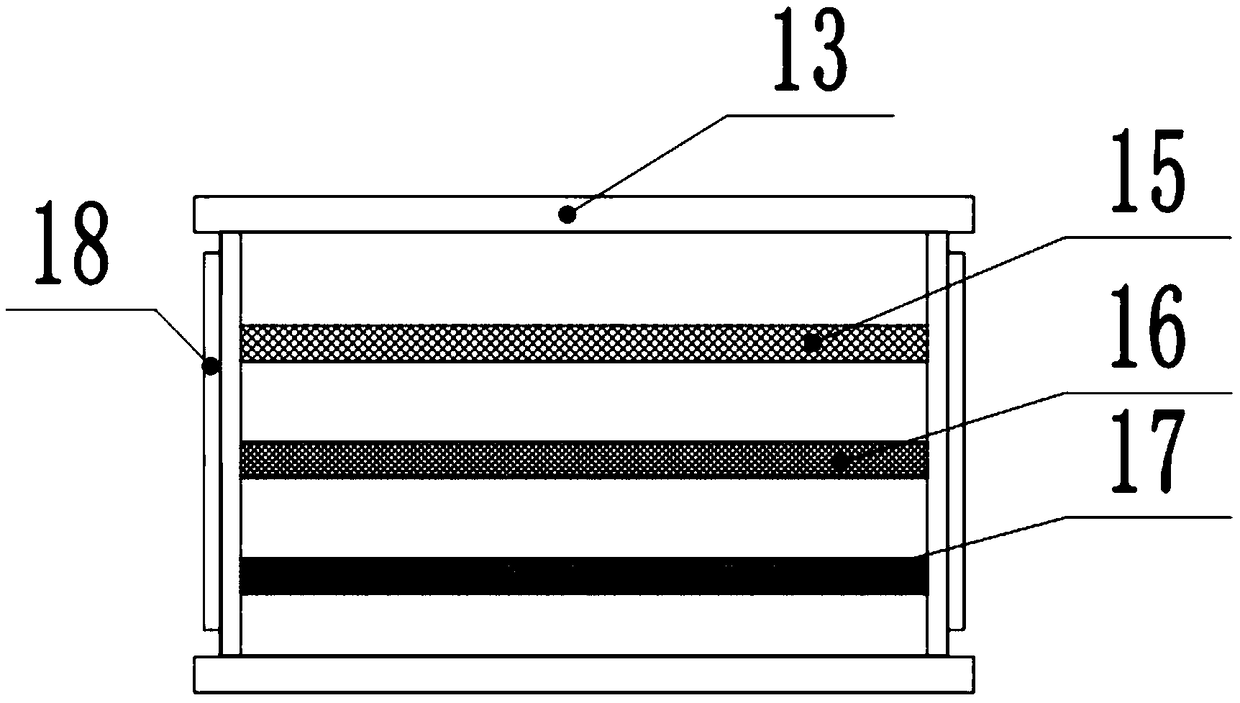

[0020] see Figure 1-3 , an integrated device for grain drying and screening, comprising a chassis 1, a paving device 5, a hot air blower 6, a screening box 13 and an impurity box 23, a support plate 2 is fixedly installed on the outer wall of the right side of the chassis 1, and the support plate 2 is fixedly installed with a feeding funnel 3 through a bracket, and the feeding funnel 3 is connected with the inside of the cabinet 1 through a feeding pipe 4. A feeding motor 8 is fixedly installed on the outer wall of the rear side of the cabinet 1, and the output of the feeding motor 8 is axial. Front and extend into the inside of the cabinet 1, a driving wheel 9 is fixedly installed on the output shaft of the feeding motor 8, and a driven wheel 10 is also rotatably installed inside the cabinet 1, and a conveyor belt 11 is connected between the driving whee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com