Material and thin film with formaldehyde adsorption and absorption functions and preparation method of material and thin film

A technology for absorbing formaldehyde and functions, applied in the field of functional materials and film preparation, can solve the problems of corrosion products, product pollution, product surface pollution, etc., and achieve the effect of lasting effectiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

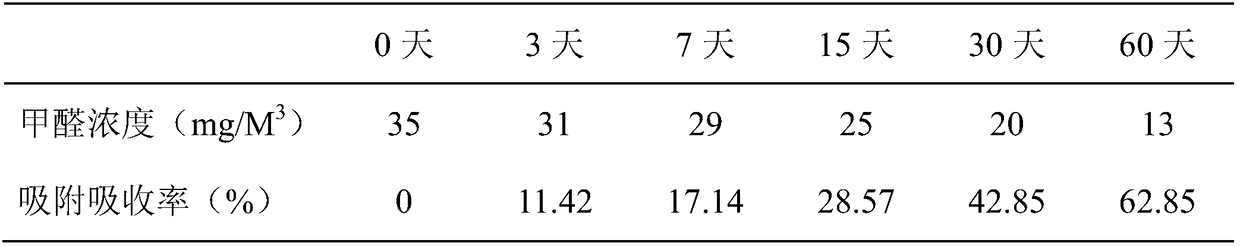

Examples

Embodiment 1

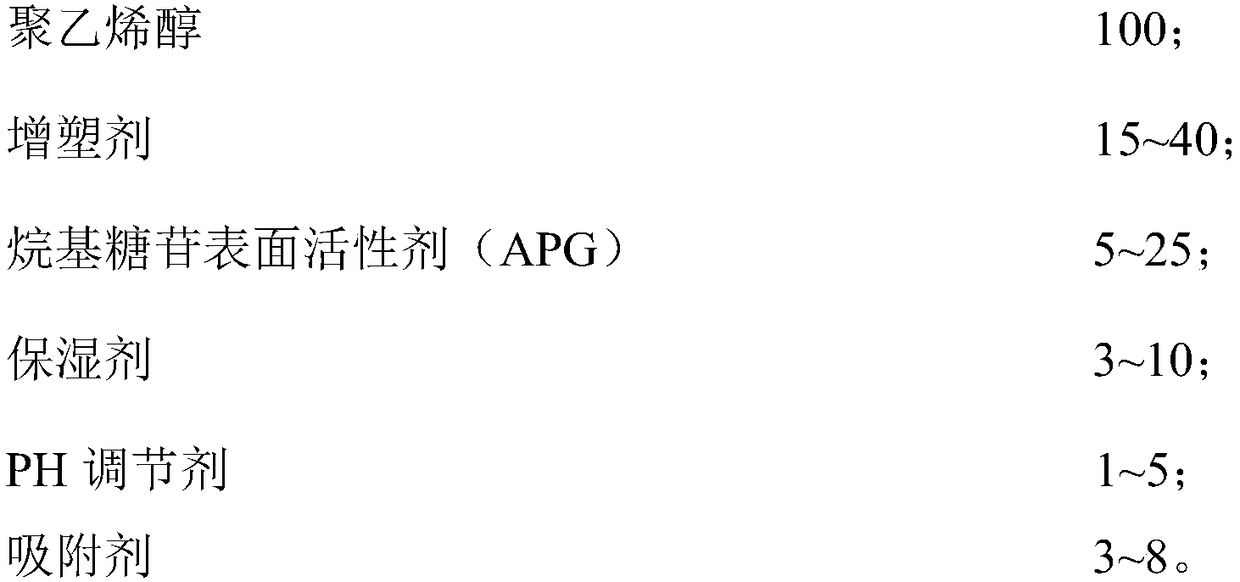

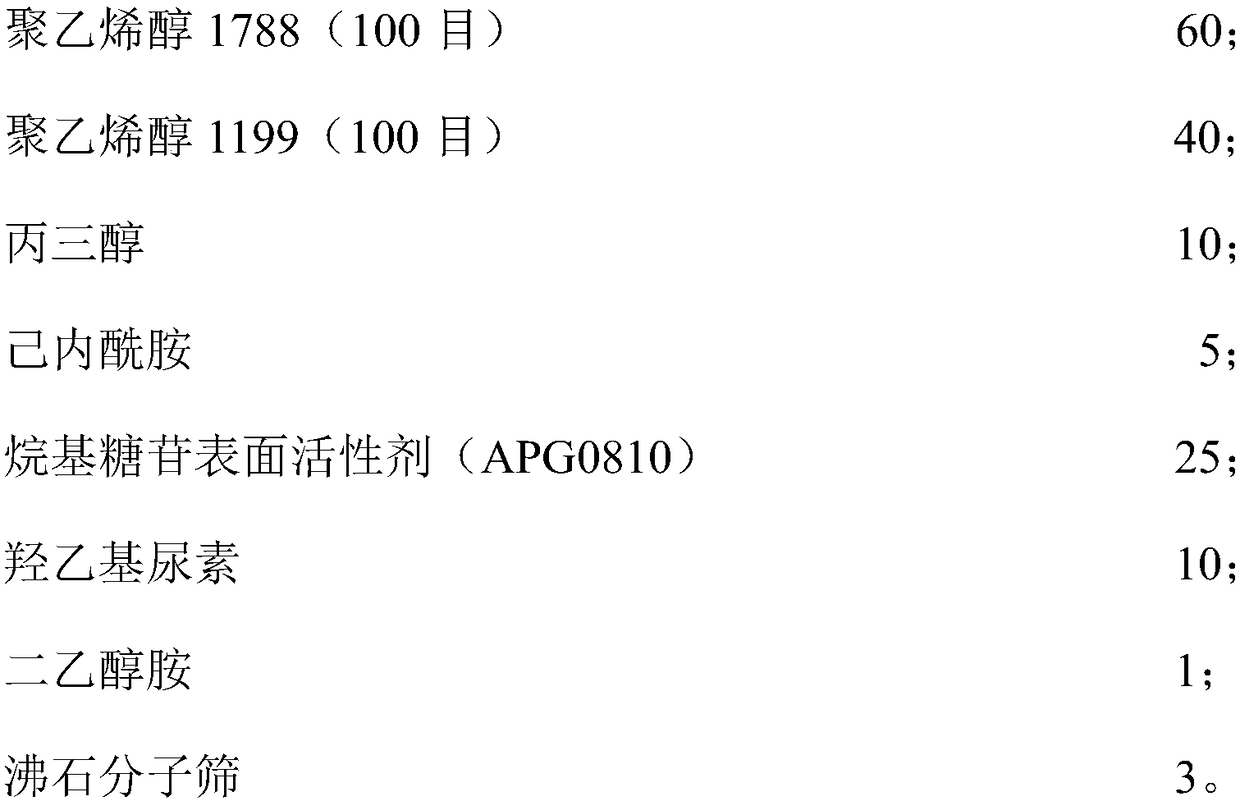

[0040] A material with the function of absorbing formaldehyde, in parts by weight (kg), comprising the following components:

[0041]

[0042] The preparation of the above-mentioned material with the function of absorbing formaldehyde comprises the following steps:

[0043] (1) After weighing the components according to the above parts by weight, add all the solid powder raw materials polyvinyl alcohol, zeolite molecular sieve, and caprolactam into the high-speed mixer, start the low-speed (300 rpm, the same below) pre-mixing for 5 minutes, Start high-speed stirring (1500 rpm, the same below) and stir and mix for 10 minutes;

[0044] (2) Then add glycerol, APG0810, hydroxyethyl urea and diethanolamine under high-speed stirring, continue to keep stirring at high speed for 30 minutes after adding, transfer to low-speed discharge, and set aside after the mixture is cooled;

[0045] (3) Extrude and granulate the mixed material after stirring and mixing through a twin-screw ext...

Embodiment 2

[0053] A material with the function of absorbing formaldehyde, in parts by weight (kg), comprising the following components:

[0054]

[0055] The preparation of the above-mentioned material with the function of absorbing formaldehyde comprises the following steps:

[0056] (1) After weighing the components according to the above weight parts, add all the solid powder raw materials polyvinyl alcohol and silicon dioxide into the high-speed mixer, start the low-speed (300 rpm, the same below) pre-mixing for 5 minutes, start High-speed stirring (1500 rpm, the same below) stirring and mixing for 10 minutes;

[0057] (2) Then add ethylene glycol, formamide, APG0814, hydroxyethyl urea and triethanolamine under high-speed stirring, continue to keep stirring at high speed for 30 minutes after adding, transfer to low-speed discharge, and set aside after the mixture is cooled;

[0058] (3) After the mixed material that has been stirred and mixed is extruded and made by a twin-screw ...

Embodiment 3

[0066] A material with the function of absorbing formaldehyde, in parts by weight (kg), comprising the following components:

[0067]

[0068] The preparation of the above-mentioned material with the function of absorbing formaldehyde comprises the following steps:

[0069] (1) After weighing the components according to the above parts by weight, add all the solid powder raw materials polyvinyl alcohol and silica alumina into the high-speed mixer, start the low speed (300 rpm, the same below) and pre-mix for 5 minutes , start high-speed stirring (1500 rpm, the same below) and stir and mix for 10 minutes;

[0070] (2) Then add ethylene glycol, acetamide, APG0816, hydroxyethyl urea and triethanolamine under high-speed stirring, continue to keep stirring at high speed for 30 minutes after the addition, transfer to low-speed discharge, and set aside after the mixture is cooled;

[0071] (3) After the material that has been stirred and mixed is extruded and made by a twin-screw...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com