SCR (Selective Catalytic Reduction) denitrification, anti-blocking and effect-increasing system

An anti-blocking and denitrification technology, applied in the field of SCR denitrification system, can solve the problems of increased operating costs, uneven distribution, and increased escape volume of the system, and achieve the effect of reducing the problem of ash accumulation, reducing ash blocking and covering a large area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

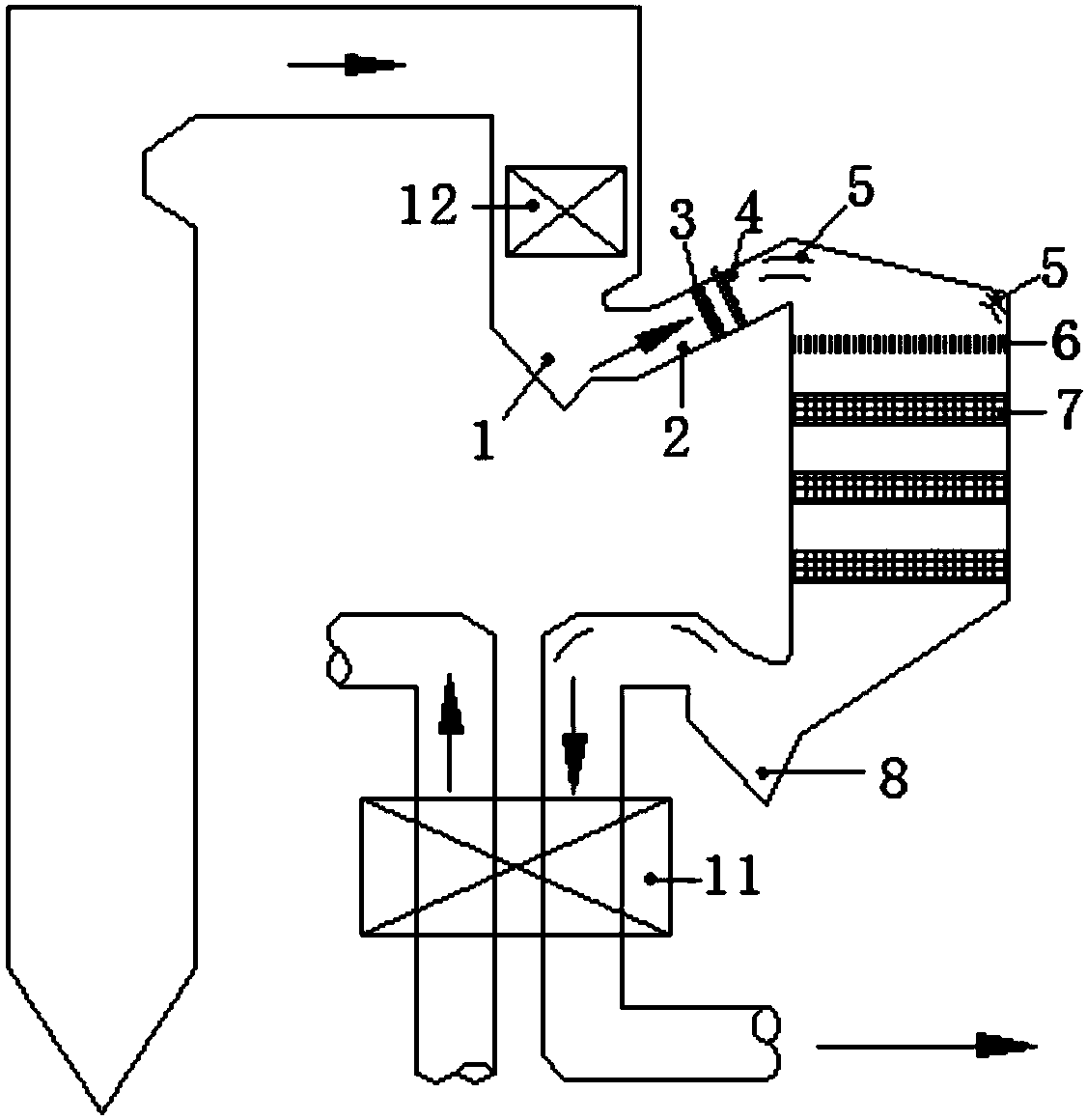

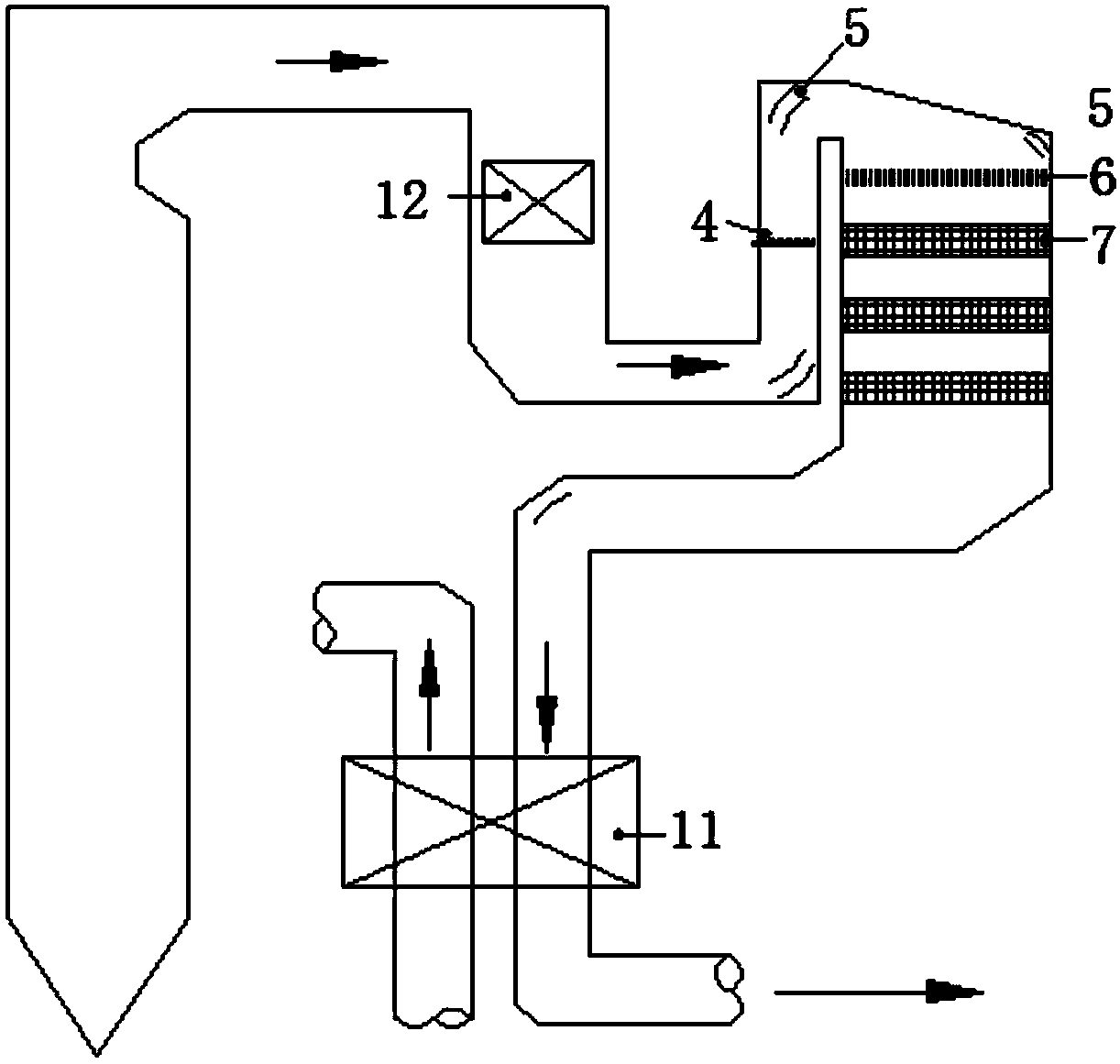

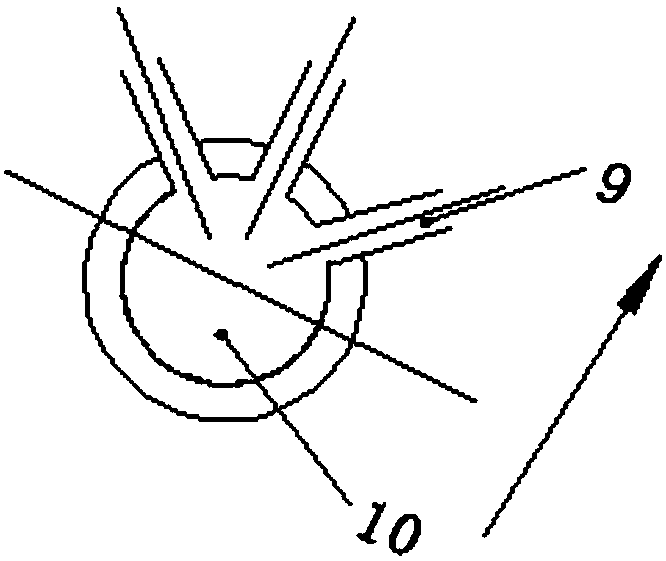

[0029] Existing SCR denitrification systems such as figure 2 As shown, the ammonia injection grid 4 is arranged horizontally in the conventional SCR denitrification system. Since the flue is arranged vertically, the ammonia injection direction of the ammonia injection grid 4 is the same as that of the flue gas flow. Refer to Figure 4 Generally, the nozzle adopts a single nozzle and is arranged vertically upward. A large amount of fly ash carried in the flue gas will fall into the nozzle due to gravity, thereby blocking the nozzle and seriously affecting the uniformity of ammonia nitrogen. In addition, when the flue gas flow carrying a large amount of fly ash passes through the SCR denitration catalyst layer 7 from top to bottom, the fly ash promotes ash intake and ash deposition in the SCR denitration catalyst layer 7 under the action of gravity.

[0030] This embodiment proposes an SCR denitrification anti-blocking efficiency improvement system, including an inlet flue, an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com