Automatic current equalizing method and device of vibrostand power amplifier

An automatic and powerful technology, applied in the direction of measuring device, vibration test, machine/structural component test, etc., can solve the problems of increasing the construction amount of commissioning personnel and failing to achieve the effect of current equalization, so as to reduce the difficulty of construction and achieve stable, accurate and uniform flow effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

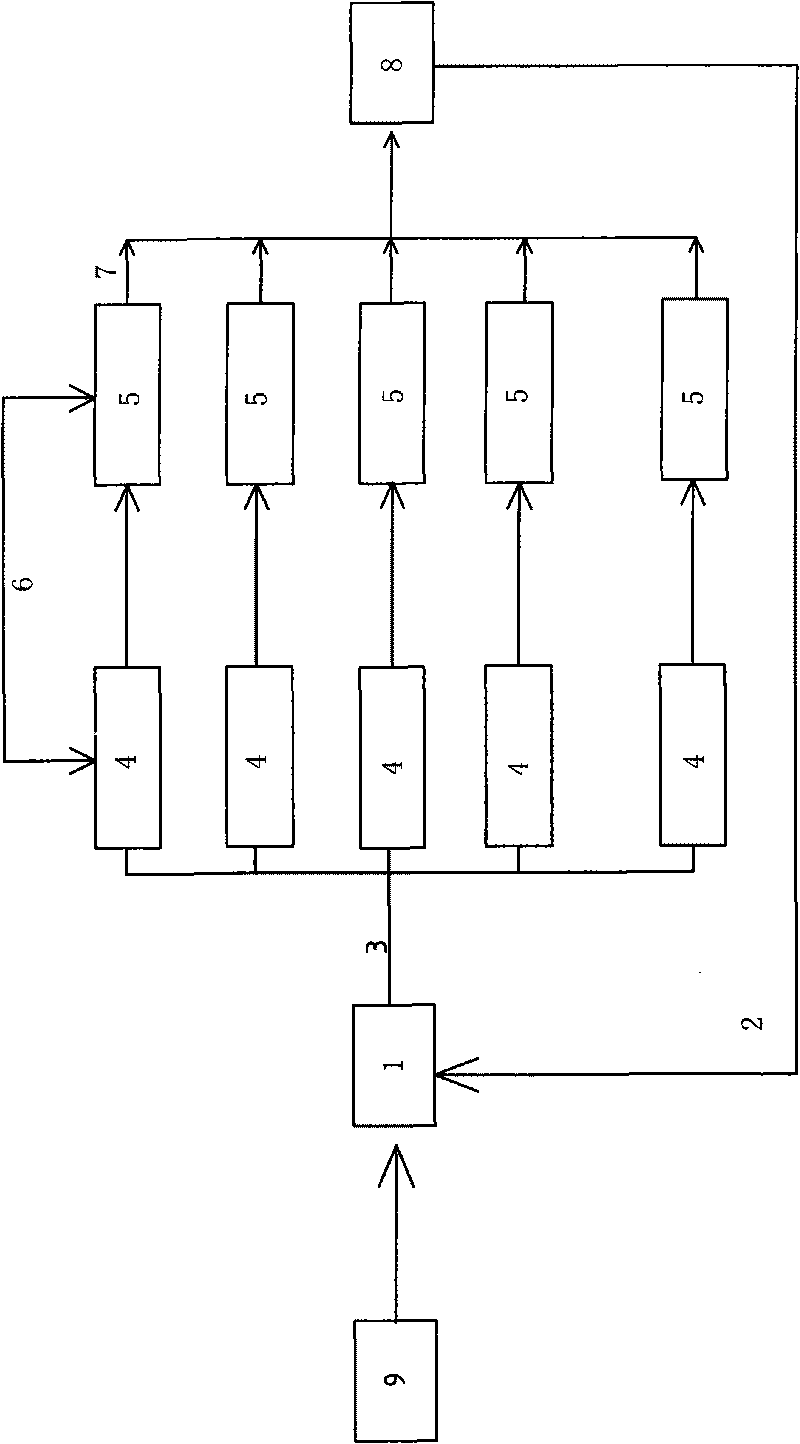

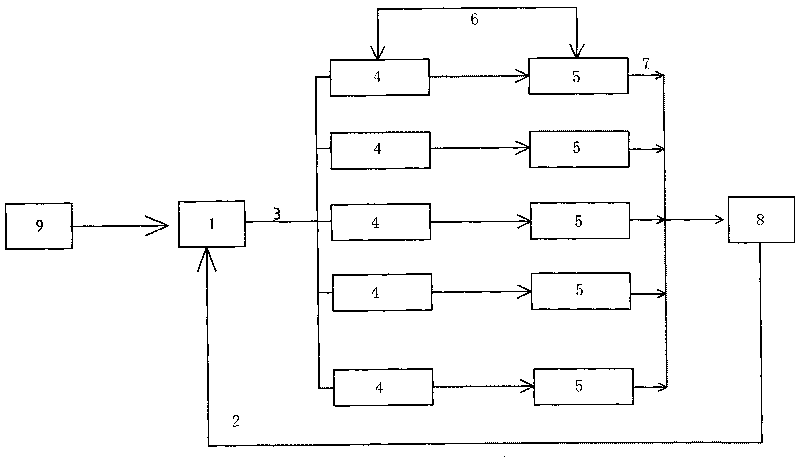

[0024] Such as figure 1 As shown, the automatic current sharing device for the power amplifier of the vibrating table includes a digital modulation module 1, the input end of the digital modulation module 1 is connected to a controller unit 9, and its output end is connected to the input end of a power amplifier unit through a communication bus 3. The power amplifier unit includes a plurality of power amplifier modules 4 arranged in parallel and a plurality of current sampling circuits 5 respectively correspondingly connected to each power amplifier module 4, and a branch current feedback loop 6 is also set between each current sampling circuit and the corresponding power amplifier modules, The output end of the power amplifier unit is connected to a vibrating table body, and the vibrating table body 8 is connected to the digital modulation module 1 through a total current feedback loop 2 .

[0025] The working process of the automatic current sharing device for the power ampl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com