High-power anti-surge alloy sheet resistor with double-sided resistive layer structure

A resistance layer, high-power technology, applied in the direction of resistance terminals/electrodes, resistors, resistor parts, etc., can solve the problems of poor resistance to surge resistance, shortened long-term service life of resistors, and reduced reliability of resistors, etc. , to achieve the effect of improving heat conduction, uniform heat distribution, and reducing calorific value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

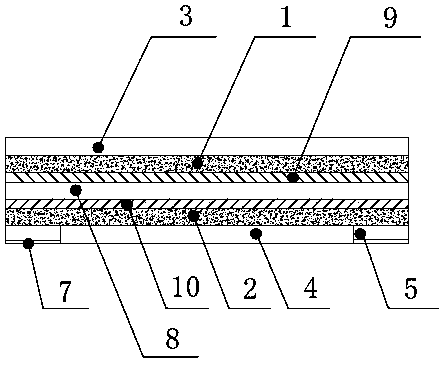

[0022] Example 1: Reference figure 1 :

[0023] A high-power anti-surge alloy sheet resistor with a double-sided resistance layer structure, comprising: a heat dissipation substrate 8, the upper and lower sides of the heat dissipation substrate 8 are respectively covered with a first resistance layer 1 and a second resistance layer 2, the heat dissipation substrate 8 and the first A first insulating layer 9 is provided between the resistance layers 1, a second insulating layer 10 is provided between the heat dissipation substrate 8 and the second resistance layer 2, and first protection layers are respectively provided outside the first resistance layer 1 and the second resistance layer 2. Layer 3 and the second protective layer 4.

[0024] Copper electrodes 5 are provided at both ends of the high-power anti-surge alloy sheet resistor with a double-sided resistive layer structure. , the total thicknesses of the second insulating layer 10 , the first protective layer 3 , and ...

Embodiment 2

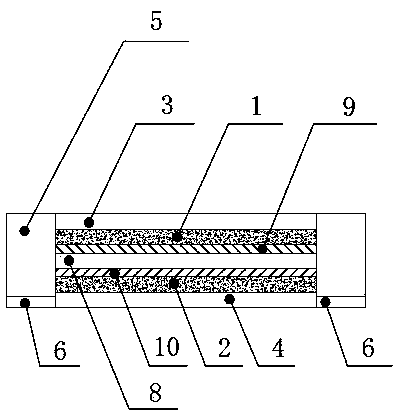

[0027] Example 2: Reference figure 2 :

[0028] A high-power anti-surge alloy sheet resistor with a double-sided resistance layer structure, comprising: a heat dissipation substrate 8, the upper and lower sides of the heat dissipation substrate 8 are respectively covered with a first resistance layer 1 and a second resistance layer 2, the heat dissipation substrate 8 and the first A first insulating layer 9 is provided between the resistance layers 1, a second insulating layer 10 is provided between the heat dissipation substrate 8 and the second resistance layer 2, and first protection layers are respectively provided outside the first resistance layer 1 and the second resistance layer 2. Layer 3 and the second protective layer 4.

[0029] Copper electrodes 5 are provided at both ends of the high-power anti-surge alloy sheet resistor with a double-sided resistive layer structure. , the total thicknesses of the second insulating layer 10 , the first protective layer 3 , and...

Embodiment 3

[0032] Example 3: Reference image 3 :

[0033] A high-power anti-surge alloy sheet resistor with a double-sided resistance layer structure, comprising: a heat dissipation substrate 8, the upper and lower sides of the heat dissipation substrate 8 are respectively covered with a first resistance layer 1 and a second resistance layer 2, the heat dissipation substrate 8 and the first A first insulating layer 9 is provided between the resistance layers 1, a second insulating layer 10 is provided between the heat dissipation substrate 8 and the second resistance layer 2, and first protection layers are respectively provided outside the first resistance layer 1 and the second resistance layer 2. Layer 3 and the second protective layer 4.

[0034] Copper electrodes 5 are provided at both ends of the high-power anti-surge alloy sheet resistor with a double-sided resistive layer structure. , the total thicknesses of the second insulating layer 10 , the first protective layer 3 , and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com