Splicing type rib material

A spliced and reinforced technology, applied in the direction of structural elements, building components, building reinforcements, etc., can solve the problems of broken joints, reduced work efficiency, and large length of steel bars, and achieves enhanced tightness, simple structure, and stable connection. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

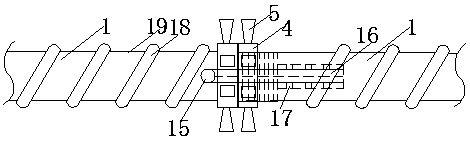

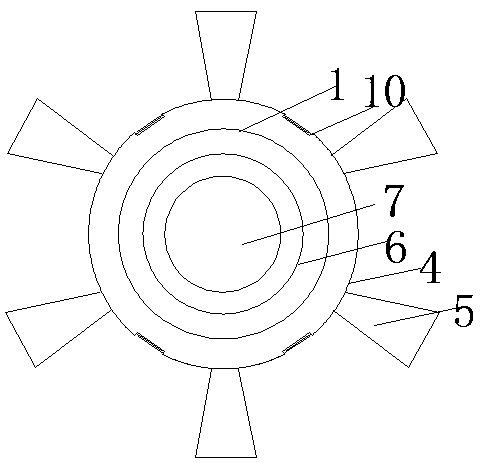

[0018] Attached below Figure 1-5 The structure, principle and working process of the present invention will be further described with specific embodiments, but the protection scope of the present invention is not limited thereto.

[0019] It should be noted that the embodiments provided by the present invention are only for effectively explaining the technical characteristics of the present invention, and the positioning words such as left, right, upper end, and lower end are only for better understanding of the embodiments of the present invention. The description should not be regarded as a limitation on the technical solution of the present invention.

[0020] A kind of spliced reinforcement, the right end of the single reinforcement 1 is provided with a protruding part 2, the left end is provided with a connecting part 3, and the left side of the protruding part 2 and the left end of the single reinforcement 1 are respectively provided with Reinforcement ring 4, on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com