Gasket placement improved mechanism of high speed wire rod baling machine

A technology of packing machine and gasket, applied in the parts and packaging of strapping machinery, can solve the problems of packing gasket offset, unguaranteed packing quality, and high labor intensity of workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

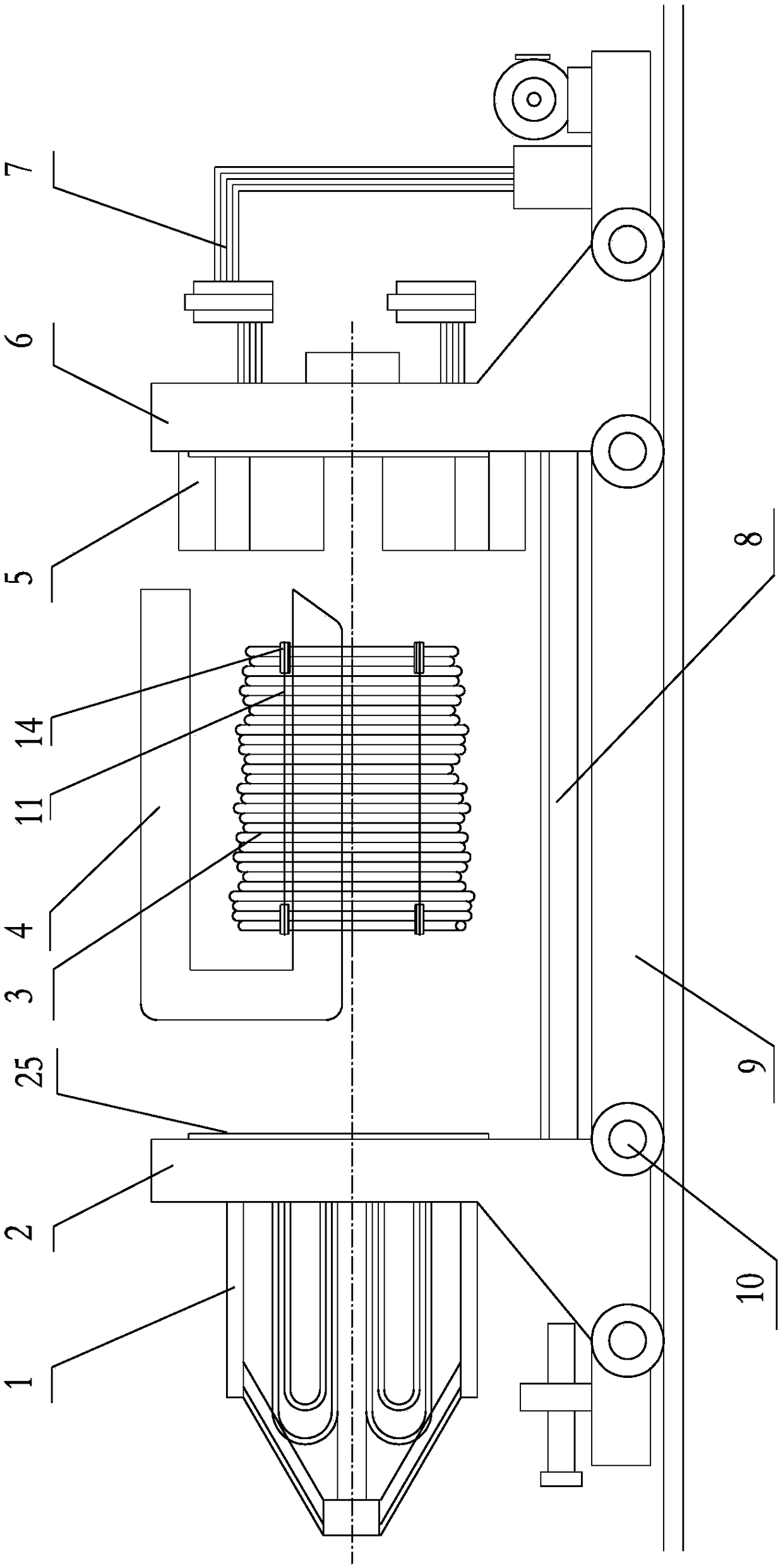

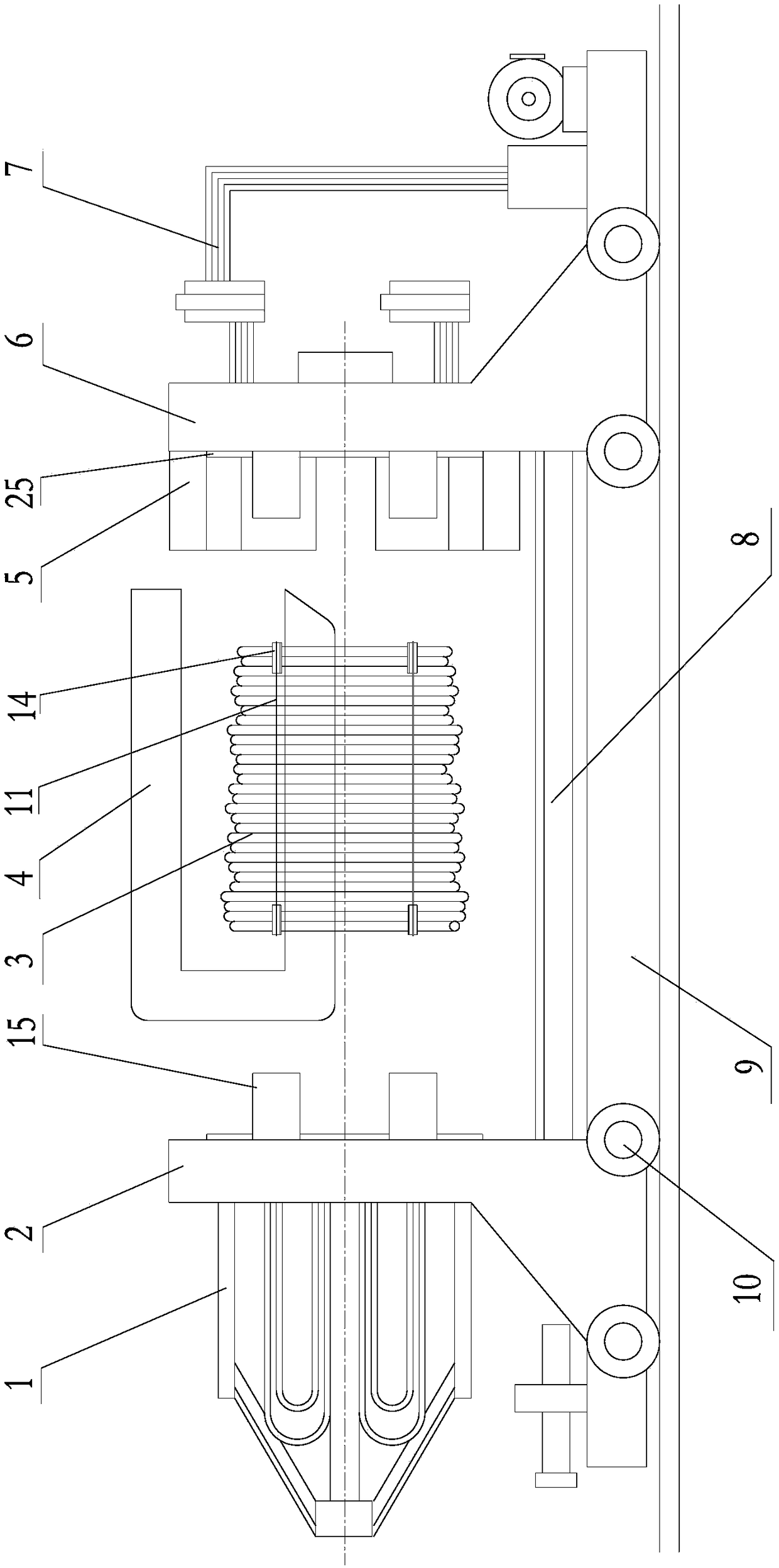

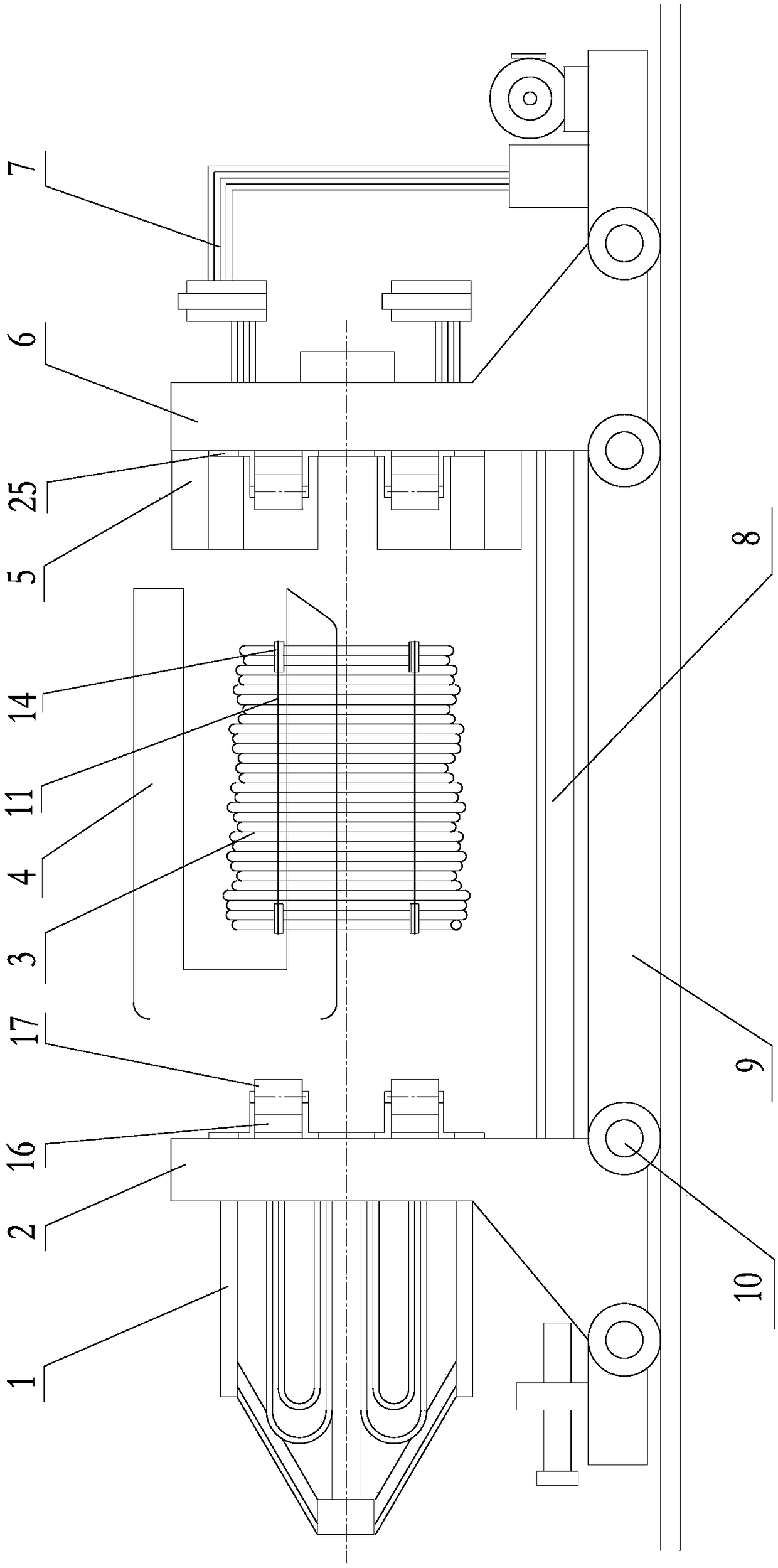

[0084] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0085] An improved gasket placement mechanism for a high-wire wire rod baler, the baler includes two pressing plates 2 that move back and forth at both ends of the pressing direction;

[0086] The two opposing pressing surfaces of the pressing plate 2 are fixed with circular anti-frustration discs 25 with a certain thickness, and the four opposite corners of the pressing plate 2 and the anti-frustration discs 25 are provided with four wire grooves 18 for binding steel wires. The wire groove 18 divides the anti-frustration disc 25 into four fan-shaped plates of upper, lower, left and right;

[0087] Continuous push mechanisms 15 for gaskets 14 are respectively provided at the four opposite corners of the pressing plate 2;

[0088] The gasket 14 is a metal sheet or a chemically synthesized sheet whose contact surface hardness is lower than that of steel;

[0089] The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com