Preparation method of superhydrophobic super-lipophilic nanofiber membrane based on layer-by-layer self-assembly technology for oil-water mixture separation

An oil-water separation membrane, layer-by-layer self-assembly technology, applied in separation methods, membrane technology, liquid separation, etc., can solve problems such as lack of mechanical integrity, and achieve the effect of improving oil-water separation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] equipped with mechanical stirrer, thermometer, N 2 Add BPDA and PDA to the dry four-necked flask leading out the inlet and outlet tubes, and mix well. Under vigorous mechanical stirring, DMAc was added. After reacting at -5°C for 12 hours, the phenomenon of rod climbing began to appear, and then the reaction was terminated by exposing the reaction to air.

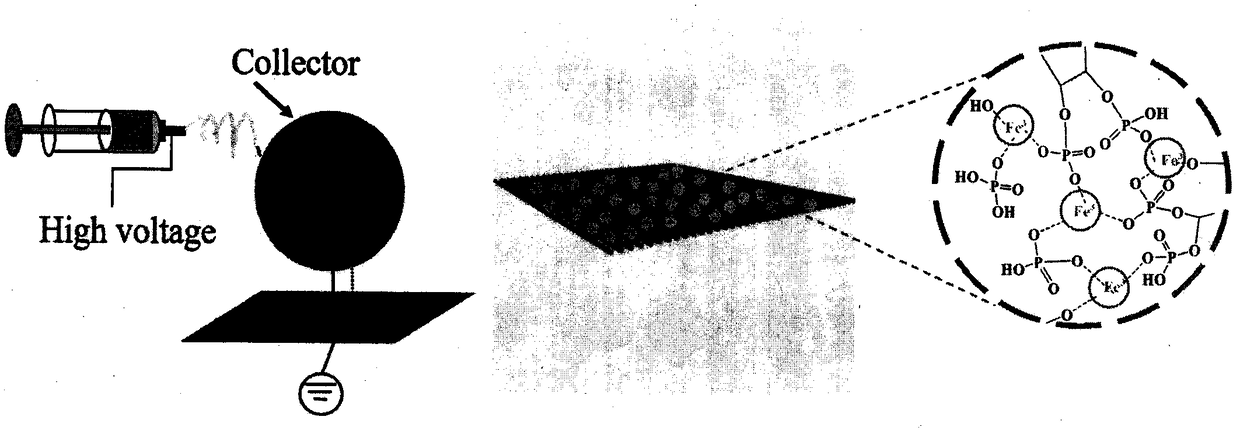

[0021] The preparation of polyamic acid (PAA) fiber film uses the DMAc solution of 3wt%PAA, contains the hexadecyltrimethylammonium bromide (increasing electrical conductivity) of 1‰ (wt%), at voltage 25kV (+15, Spinning in a high-voltage electrostatic field of -10kV), the distance from the needle point to the drum is about 15cm, the collector is a grounded flywheel with adjustable speed, the speed is 2000 rpm, and the speed of electrospinning is 0.35ml / h, such as figure 1 shown. The electrospun polyamic acid fiber membrane was subjected to 150°C / 1h, 200 / 1h, 250°C / 1h, 300°C / 1h, 350°C / 30mim in a tube furnace protec...

Embodiment 2

[0023] (1) Accurately weigh 2.7029g of ferric chloride hexahydrate solid, dissolve it in deionized water, and set the volume to 0.1mol / L solution.

[0024] (2) Take 1 mL of 70% phytic acid solution and dissolve it with 99 mL of deionized water.

[0025] (3) Octadecyltrimethoxysilane was dissolved in tetrahydrofuran to prepare a solution with a mass concentration of 1% for later use.

[0026] (4) Immerse the membrane in the PA solution for 2 minutes, take it out, wash it with deionized water, and dry it in the air

[0027] (5) Immerse the dried film in ferric chloride solution for 2 minutes, take it out and wash it with deionized water, and dry it in the air

[0028] (6) Repeat this 5 times to ensure that the self-assembly effect can reach the expected goal

[0029] (7) Vacuum drying and curing for 2 hours at 80°C

[0030] (8) Take it out and soak it in the TMOS solution for 2 hours, take it out, and dry it in vacuum for 2 hours at 80° C. to obtain the superhydrophobic oil-w...

Embodiment 3

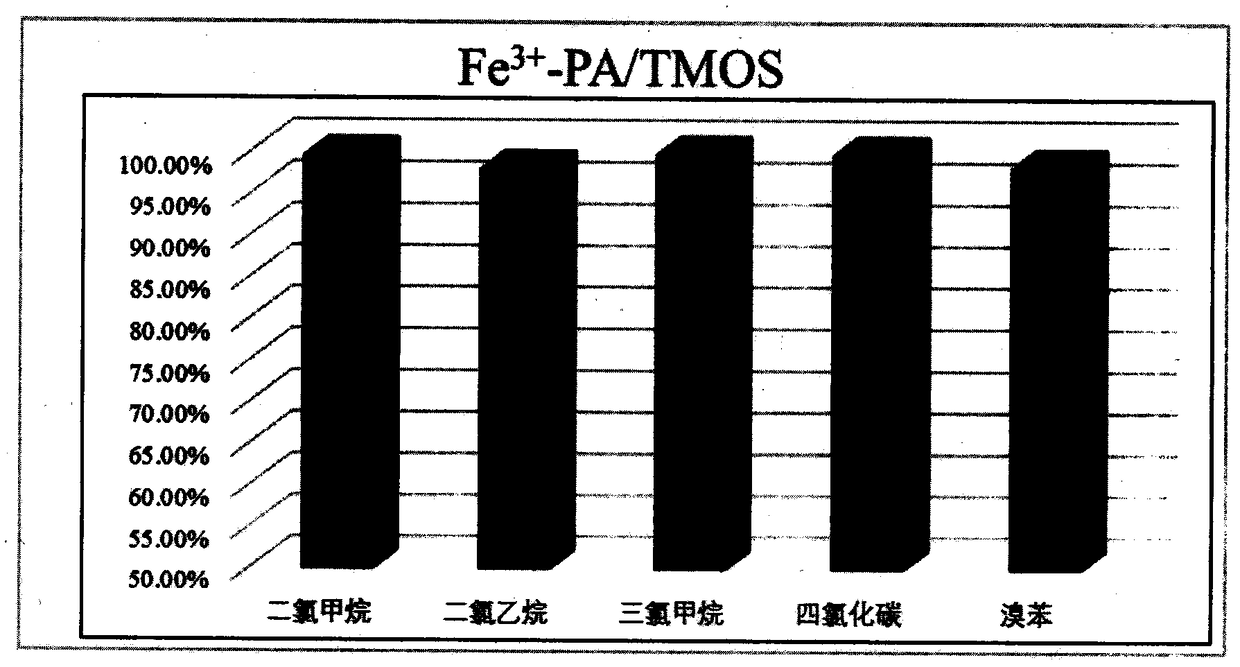

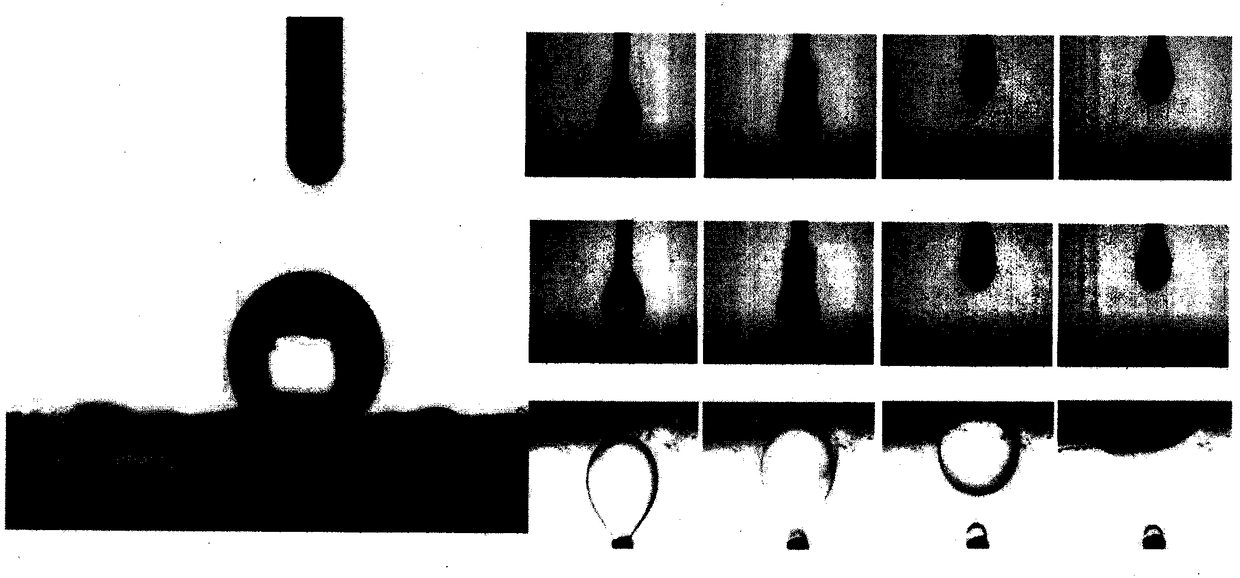

[0032] The oil-water mixture is separated by a graduated cylinder filter, and the separation efficiency is calculated by recording the liquid mass before and after separation. The filter is mainly composed of 3 parts, the upper and lower two measuring cylinder filter cups, and the FeCl prepared by the present invention is placed in the middle frosted interface. 3 -PA / TMOS modified layer-by-layer self-assembly structure PI-based oil-water separation fiber membrane, after fixing with clips, fix the whole device on the iron stand. Mix 10mL oil and 10Ml water evenly and pour it from the top of the separation device. The liquid mixture contacts the membrane at the junction, the oil phase flows into the beaker below through the membrane, and the water phase is trapped above the membrane to achieve the purpose of separation. By testing, the FeCL prepared by the present invention 3 - PA / TMOS modified layer-by-layer self-assembly structure PI-based oil-water separation fiber membrane...

PUM

| Property | Measurement | Unit |

|---|---|---|

| separation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com