Method for preparing graphene by taking graphite electrodes of waste lithium batteries as raw materials and recycling lithium

A technology for waste lithium batteries and graphite electrodes, which is applied in battery recycling, recycling by waste collectors, recycling technology, etc., can solve the problems of poor controllability, cumbersome process, and large amount of waste liquid, and achieve precise control and high efficiency. Value-added recovery technology and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1: reactor structure

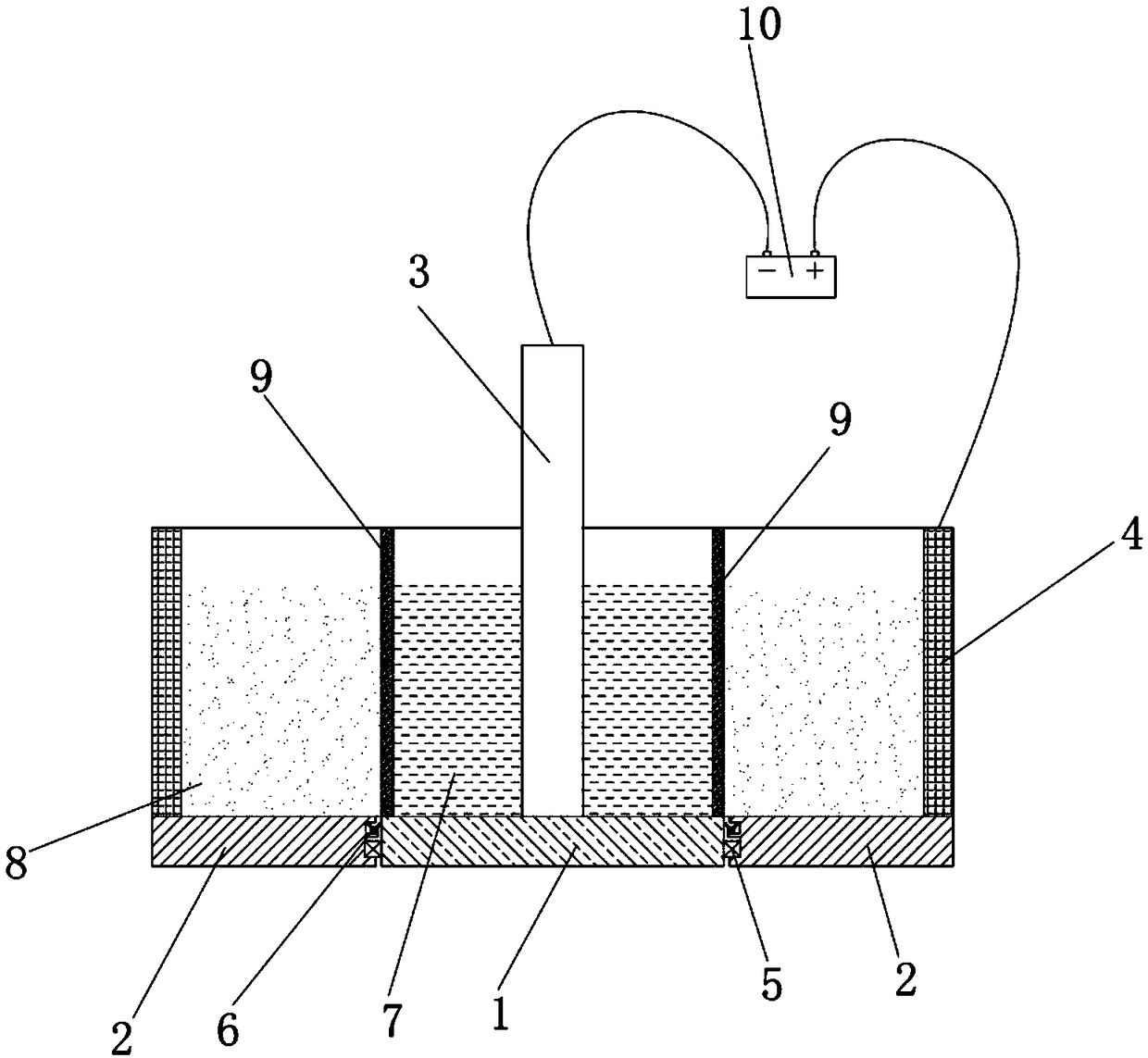

[0029] Such as figure 1 As shown, the reactor includes a central bottom plate 1, and an outer bottom plate 2 that rotates relative to the central bottom plate 1 is arranged on the outer side of the central bottom plate 1. A conductive column 3 protruding vertically upwards is arranged in the center of the upper surface of the central bottom plate 1. The outer periphery of the upper surface of the outer bottom plate 2 is provided with There is an outer baffle plate 4 that is fixed with the outer bottom plate and protrudes vertically upwards, and a semi-permeable membrane 9 that is fixed with the central bottom plate and protrudes vertically upwards is arranged on the outer periphery of the upper surface of the central bottom plate 1. The accommodating space enclosed by the semi-permeable membrane 9 and the central bottom plate 1 constitutes the cathode area 7, and the accommodating space enclosed by the semi-permeable membrane 9, the out...

Embodiment 2

[0034] Example 2: A method for preparing graphene and reclaiming lithium using graphite electrodes for waste lithium batteries as raw material

[0035] Raw materials: select waste lithium batteries, break the shell, and put the graphite negative electrode in N 2 Dry at 90° C. for 2 hours under atmosphere to remove the electrolyte, then add it into deionized water, stir, filter, and dry to obtain graphite electrode material.

[0036]Crush the graphite electrode material to a particle size of ≤10 μm, then add 2 g of the crushed graphite electrode into the anode area of the reactor containing 1 mol / L lithium sulfate solution (5°C), the solid-to-liquid ratio of the graphite electrode to the solution in the reactor is 1 : 30 (g / ml), the anode area rotates counterclockwise under the condition of a centrifugal speed of 200 rpm, and a constant voltage direct current of 1.7V is introduced at the same time, and the electrification time is 30min, and then CO is introduced into the cath...

Embodiment 3

[0037] Example 3: A method for preparing graphene and reclaiming lithium using graphite electrodes for waste lithium batteries as raw material

[0038] Raw materials: select waste lithium-ion batteries, break the shell, and put the graphite negative electrode in N 2 Dry at 90°C for 4 hours under atmosphere to remove the electrolyte, then add it into a mixture of deionized water and ethanol (volume ratio 1:1) and stir, filter and dry to obtain graphite electrode material.

[0039] The graphite electrode material is crushed to a particle size ≤ 8 μm, and then 10 g of the crushed graphite electrode is added to the anode area of the reactor containing a 3mol / L lithium chloride solution (20°C). The solid-to-liquid ratio of the graphite electrode to the solution in the reactor is 1:70 (g / ml), the anode area rotates clockwise under the condition of centrifugal speed of 300 rpm, and at the same time, 1.5V constant voltage direct current is applied for 30 minutes, the ultrasonic powe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com