Strip steel surface defect classification method

A defect classification and strip steel technology, applied in the field of visual recognition, can solve the problems of low efficiency and low accuracy of strip steel surface classification, and achieve the effect of high execution efficiency and high automatic classification accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] Below in conjunction with accompanying drawing, the present invention is illustrated

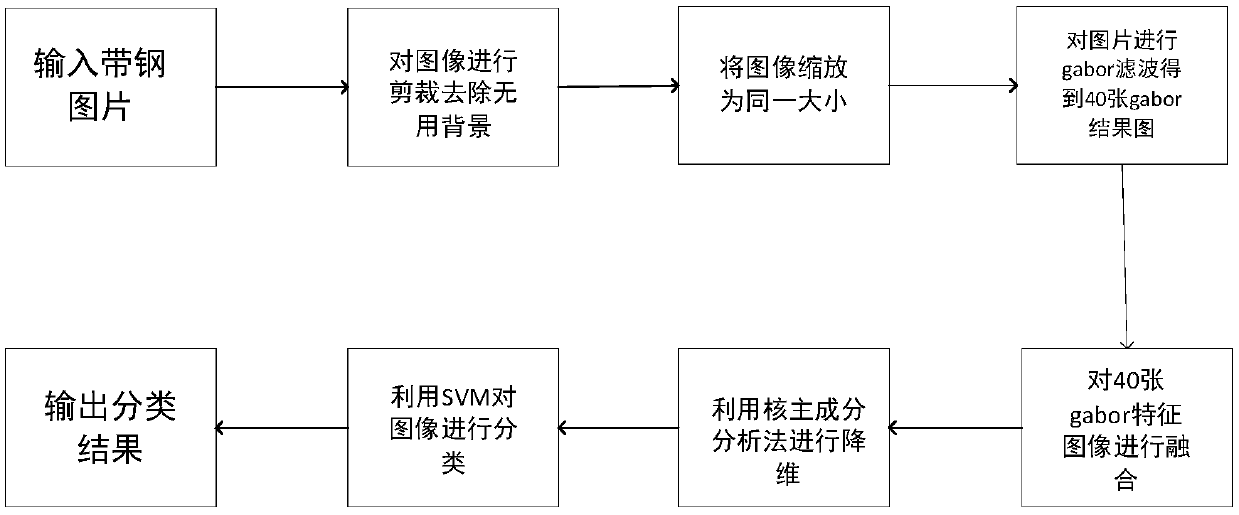

[0062] As shown in the figure, a strip steel surface defect classification method based on Gabor feature fusion block histogram includes the following steps:

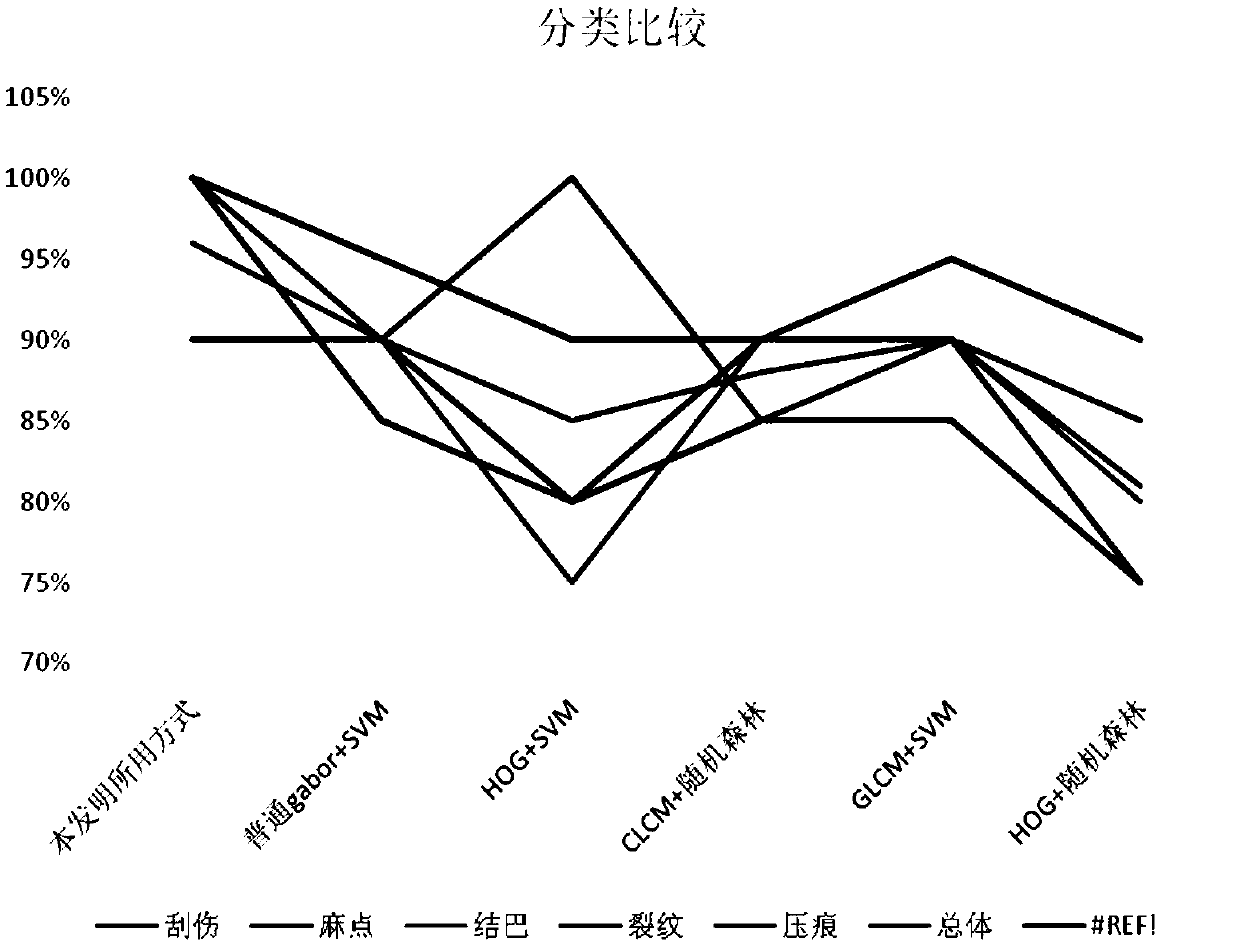

[0063] Step 1. First extract the steel strip pictures from the training sample library, and select a sample set composed of 5*20=100 sample pictures for testing. The sample set includes five common types of scratches, cracks, pits, stutters, and indentations. Typical defects on the surface of the steel strip, each 20 typical defects, select W=60 sample pictures from the sample set as the training set, and the remaining 5*20-W=40 sample pictures as the test set;

[0064] Step 2. Use linear interpolation to perform geometric normalization on all the images in the sample set, and scale the images into images with a size of 400*400 pixels;

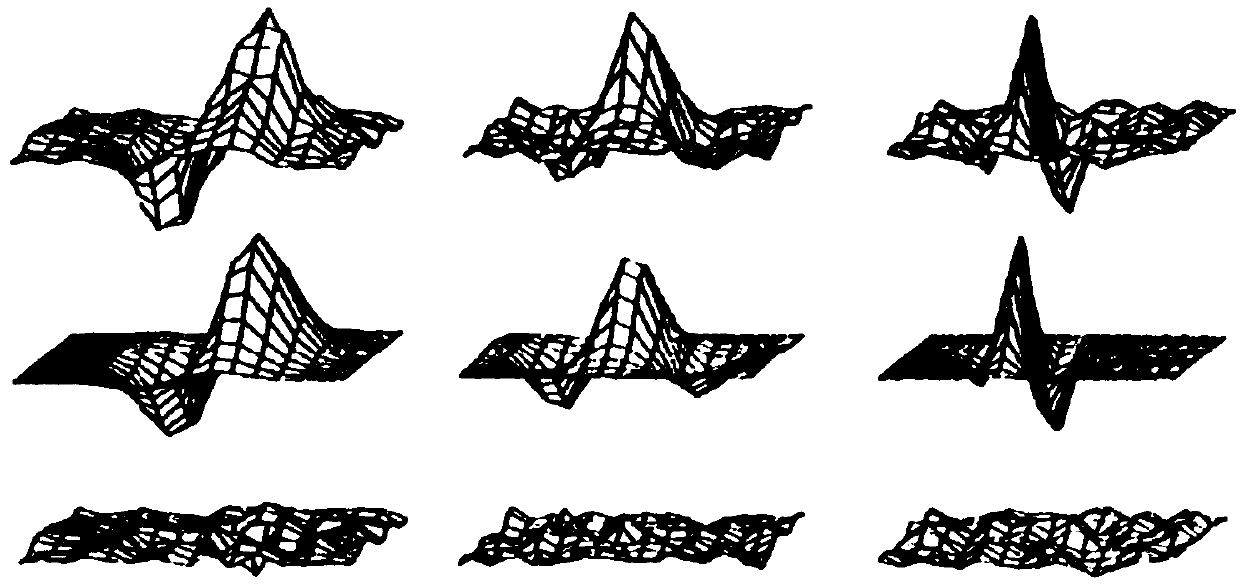

[0065] Step 3, import the geometrically normalized picture into the Gabor filter (a linear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com