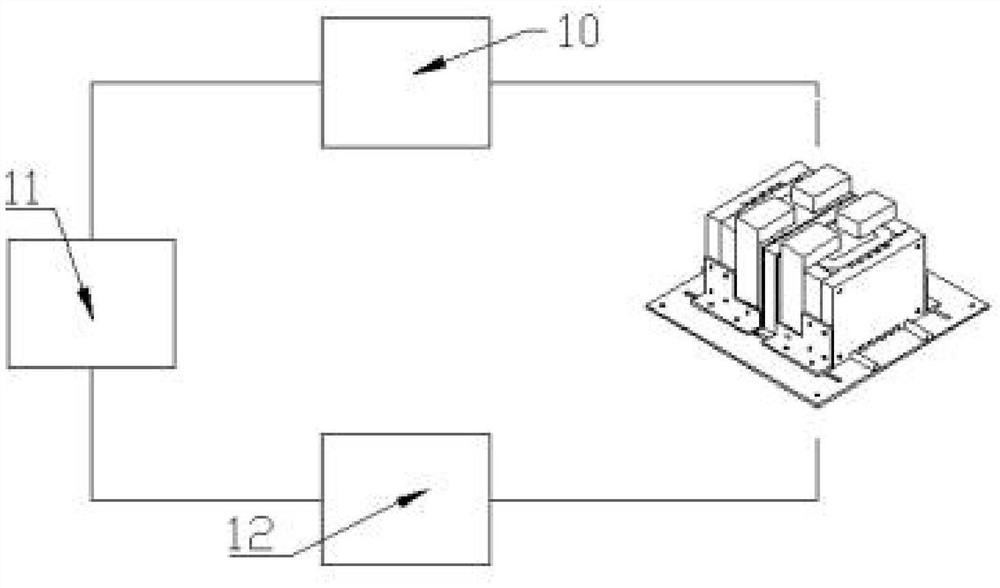

A measuring system and method for permanent magnet eddy current loss

A technology of eddy current loss and measurement system, which is applied in the direction of magnetic performance measurement, measuring device, and magnetic variable measurement, and can solve the problems of uneven distribution of eddy current and inability to reflect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

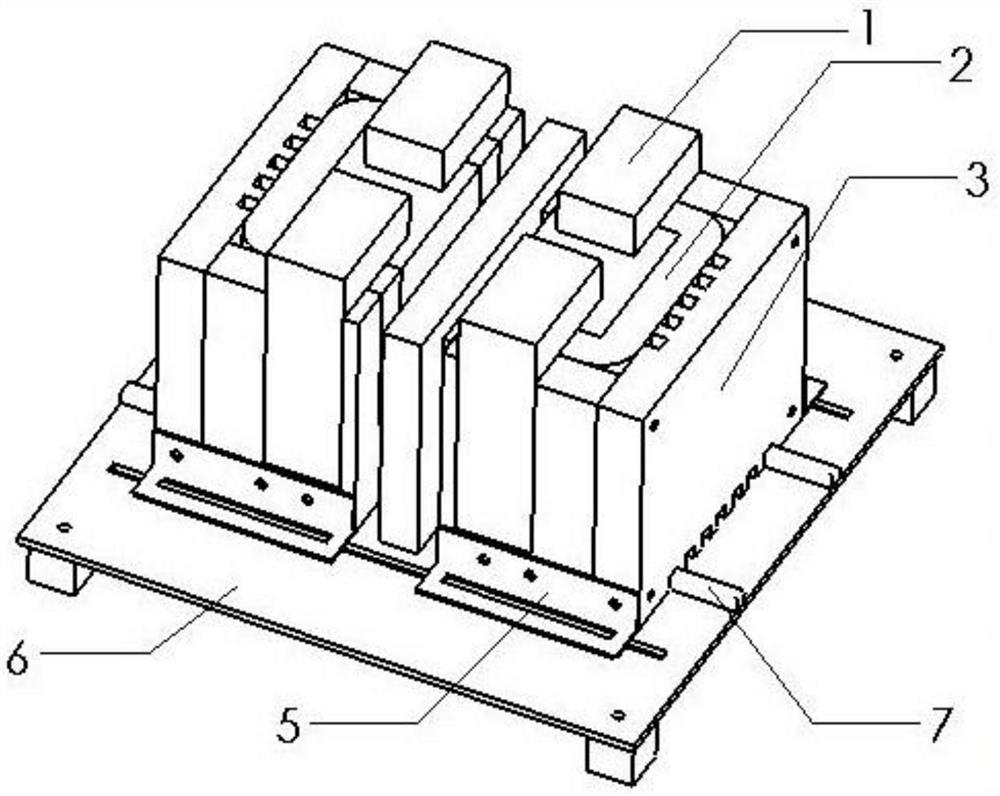

[0041] The number of excitation windings in the measuring system of permanent magnet eddy current loss in this embodiment is four, and the sample to be tested is a cubic NdFeB sample, and the sample size is 10*10*10mm (length*width*height). The excitation frequency is 50Hz.

[0042] Power amplifier model: BROCKHAUS PA50, the voltage signal is amplified 10 times, the input voltage peak value is -10V~+10V, and the output voltage peak value is -100V~+100V. The maximum effective value of the output current is 50A.

[0043] Digital signal processing unit model: NI USB-7856R.

[0044] Differential amplifier circuit model: STANFORD RESERCH SYSTEM MODEL SR560 magnification 10 to 50000 times, working frequency, DC to 1MHz.

[0045] Number of turns of excitation winding: 90 turns / piece.

[0046] The maximum external dimension of the magnetic core is 150*100*100mm (length*width*height), and the thickness is 25mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com