Combined structure of uhv equipment interconnected in-situ reaction cell and built-in mass spectrometer electric quadrupole

A technology of in-situ reaction and equipment interconnection, applied in the direction of circuits, discharge tubes, sampling devices, etc., to achieve the effect of minimizing time delay

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] In order to make the present invention more comprehensible, preferred embodiments are described in detail below with accompanying drawings.

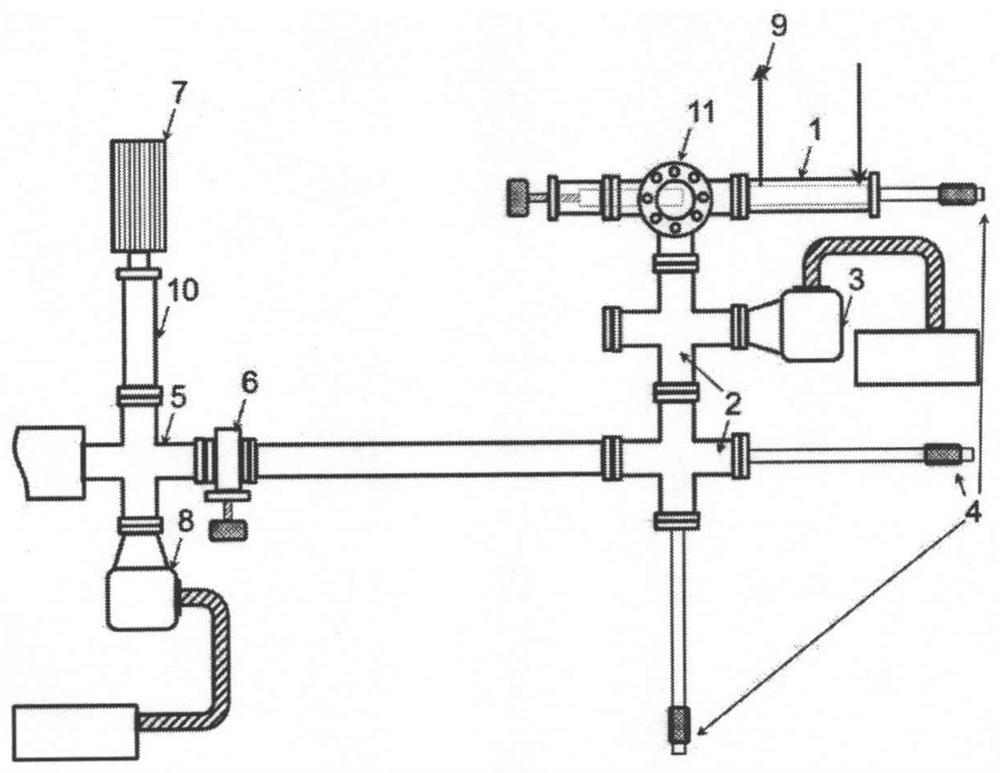

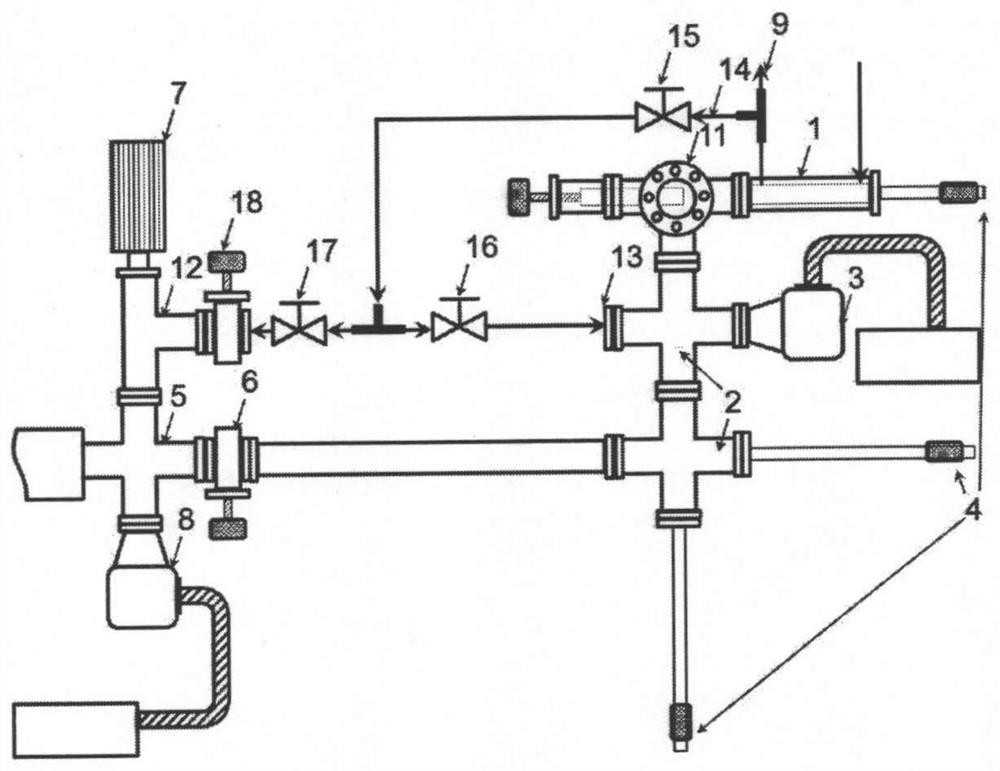

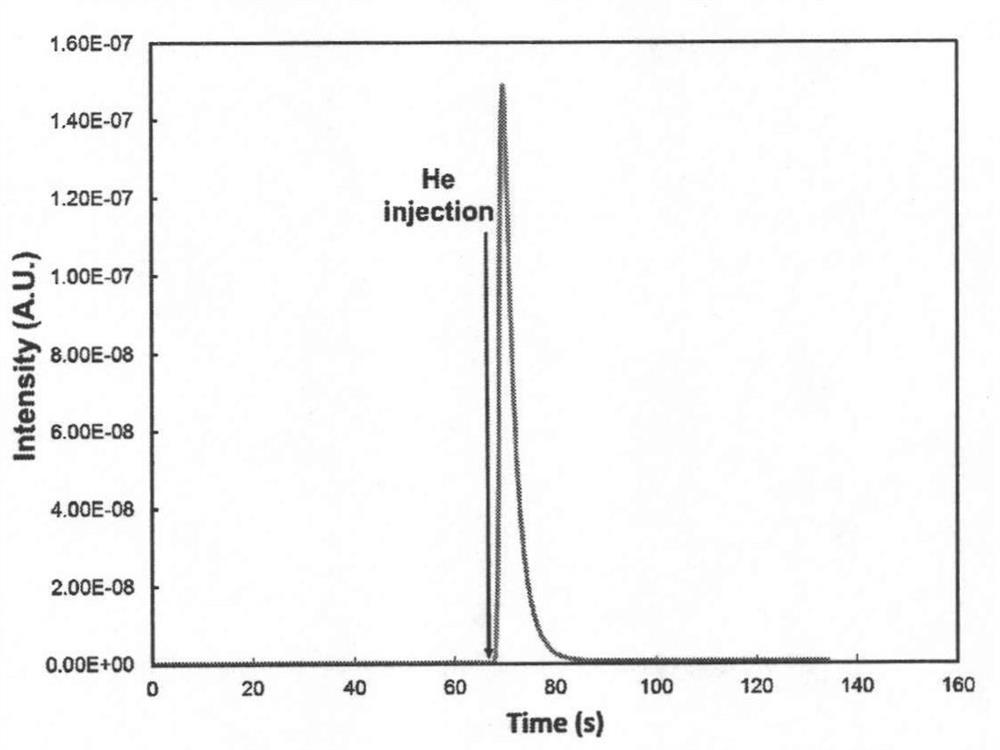

[0054] Such as figure 2 As shown, the combined structure of a UHV equipment interconnected in-situ reaction cell and a built-in mass spectrometer electric quadrupole provided by the present invention, according to the previous patent scheme, needs to complete the mass spectrometer electric quadrupole 7 pairs of in-situ reaction cell arrays. Gas line 9 sampling. In order to use the original configuration hardware of the ultra-high vacuum characterization equipment to achieve this assembly scheme, it is first necessary to change the original two vacuum flanges of the ultra-high vacuum characterization equipment into flange interfaces, which is required for real-time sampling in the previous patent scheme two vacuum ports. The first flange modification: change the straight-through flange 10 connecting the mass spectrometer quadrup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com