A method for controlling the speed of a refrigerator condenser fan

A condenser fan and speed control technology, applied in refrigerator condenser fan speed control, refrigerator field, can solve the problems of condensing fan failure false alarm, high noise, high fan power consumption, etc., achieve timely response, reduce noise, and solve fault errors The effect of the alarm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

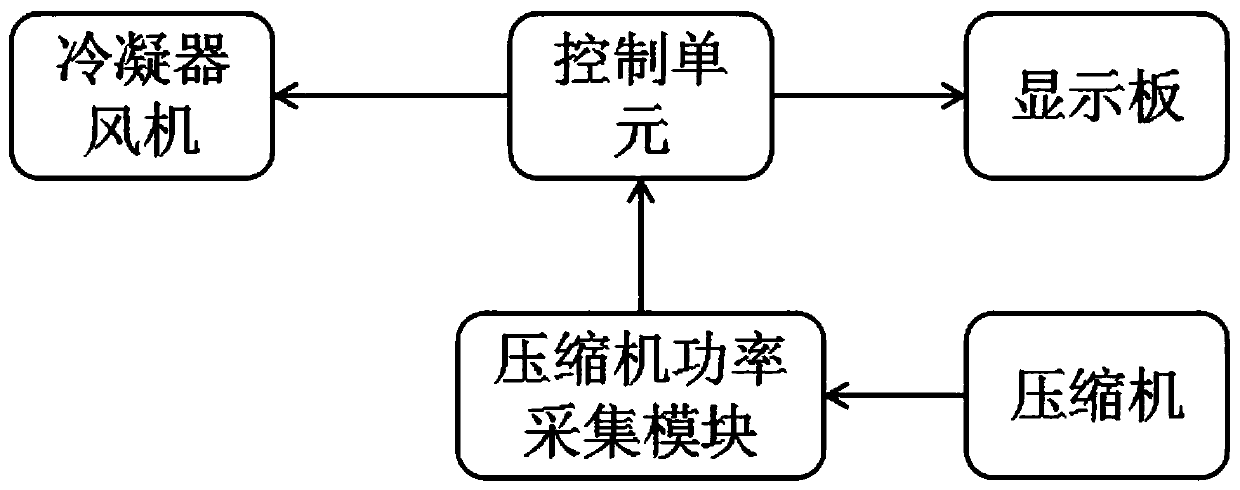

[0044] A refrigerator, including a compressor, a condenser fan, a control unit, and a compressor operation parameter acquisition module;

[0045] The compressor is an inverter compressor;

[0046] The main control board is integrated with a control unit and a compressor power acquisition module;

[0047] The control unit is respectively connected with the compressor power collection module, the condenser fan and the display board;

[0048] The compressor power collection module is electrically connected with the compressor.

[0049] A method for controlling the speed of a refrigerator condenser fan, comprising a condenser fan, a control unit, a compressor operation parameter acquisition module and a control unit, the control unit is electrically connected to the compressor operation parameter acquisition module and the condenser fan respectively, and the compressor operation parameters The acquisition module is electrically connected to the compressor;

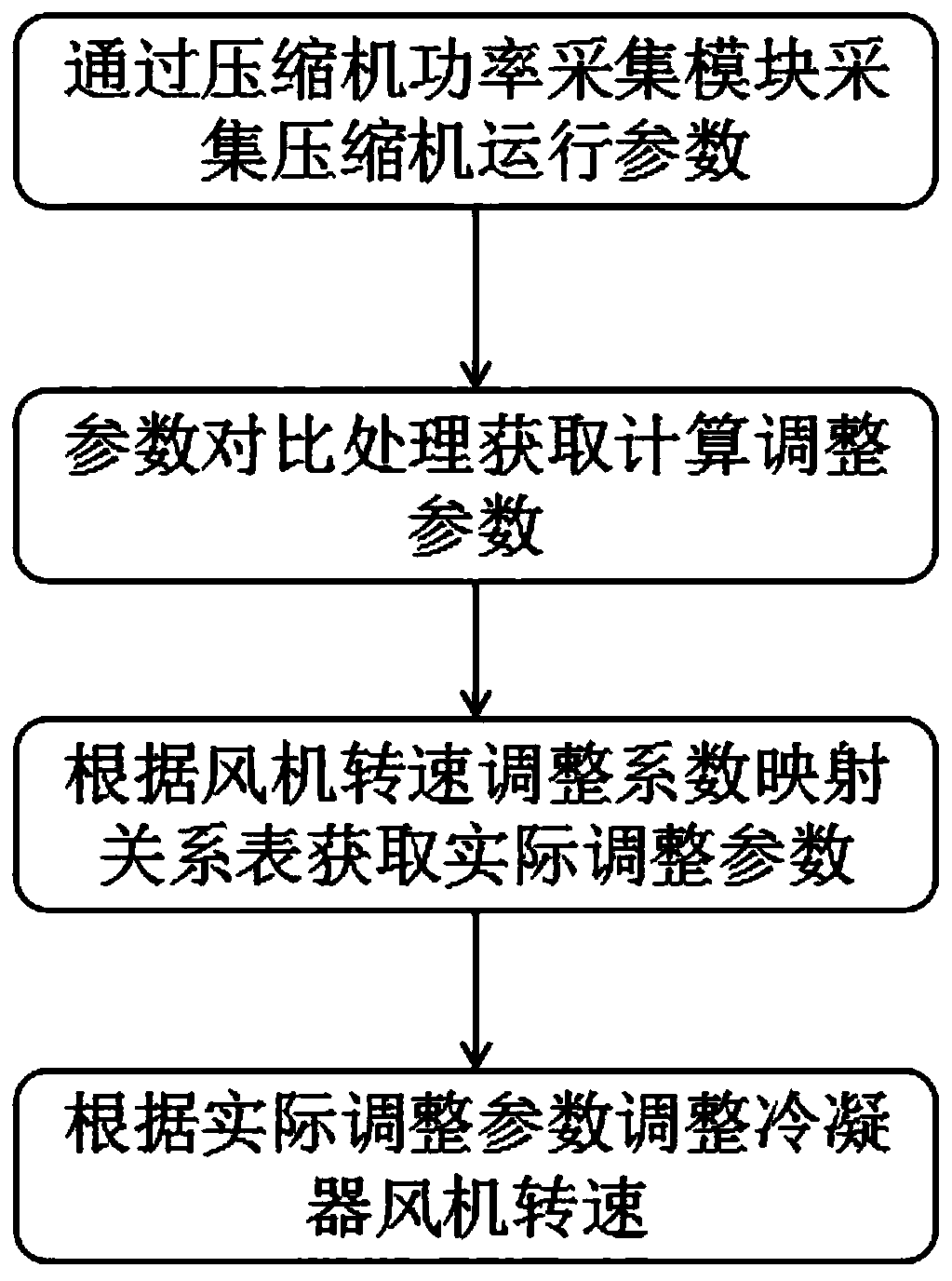

[0050] The control ...

Embodiment 2

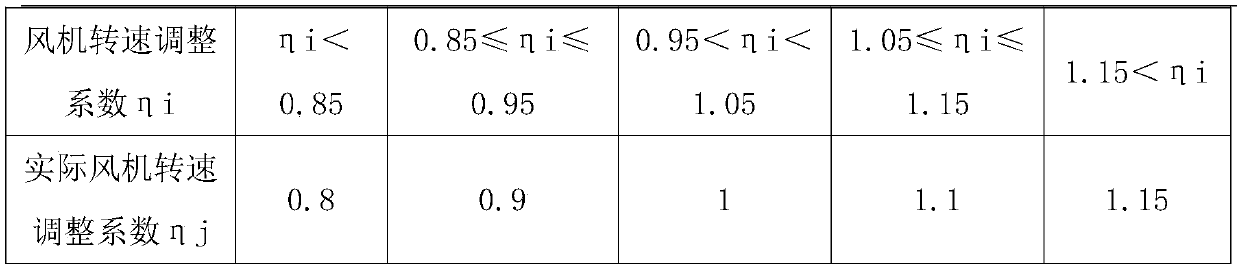

[0077] For example: when the refrigerator is powered on for the first time, the ambient temperature is 35 degrees, and the compressor runs at 3600rpm. At this time, due to the high temperature of the cabinet and the heavy load, the actual operating power of the compressor in the first half hour is about 138W (higher than the reference power)

[0078] Fan speed adjustment coefficient = 138 / 114 = 1.21, the actual execution adjustment coefficient is 1.15, then the fan speed is adjusted to 1.15*1060=1219rpm

[0079] If the ambient temperature is 12 degrees and the compressor runs at 1200rpm, the actual operating power of the compressor is about 32W, the fan speed adjustment coefficient is 32 / 38=0.84, and the actual execution adjustment coefficient is 0.8, then the fan speed is adjusted to 0.8*700= 560rpm

[0080] In practical applications, the operating power of the compressor is detected every 3 minutes, and the operating speed of the fan is determined according to the fan speed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com