Preheating and anhydration device for garbage

A garbage and drying technology, which is applied in the direction of incinerators, lighting and heating equipment, and combustion methods, can solve the problems of difficult carbon monoxide emissions, insufficient garbage combustion, and high water content in garbage, so as to reduce consumption and improve operation efficiency. Uniform, temperature-increasing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

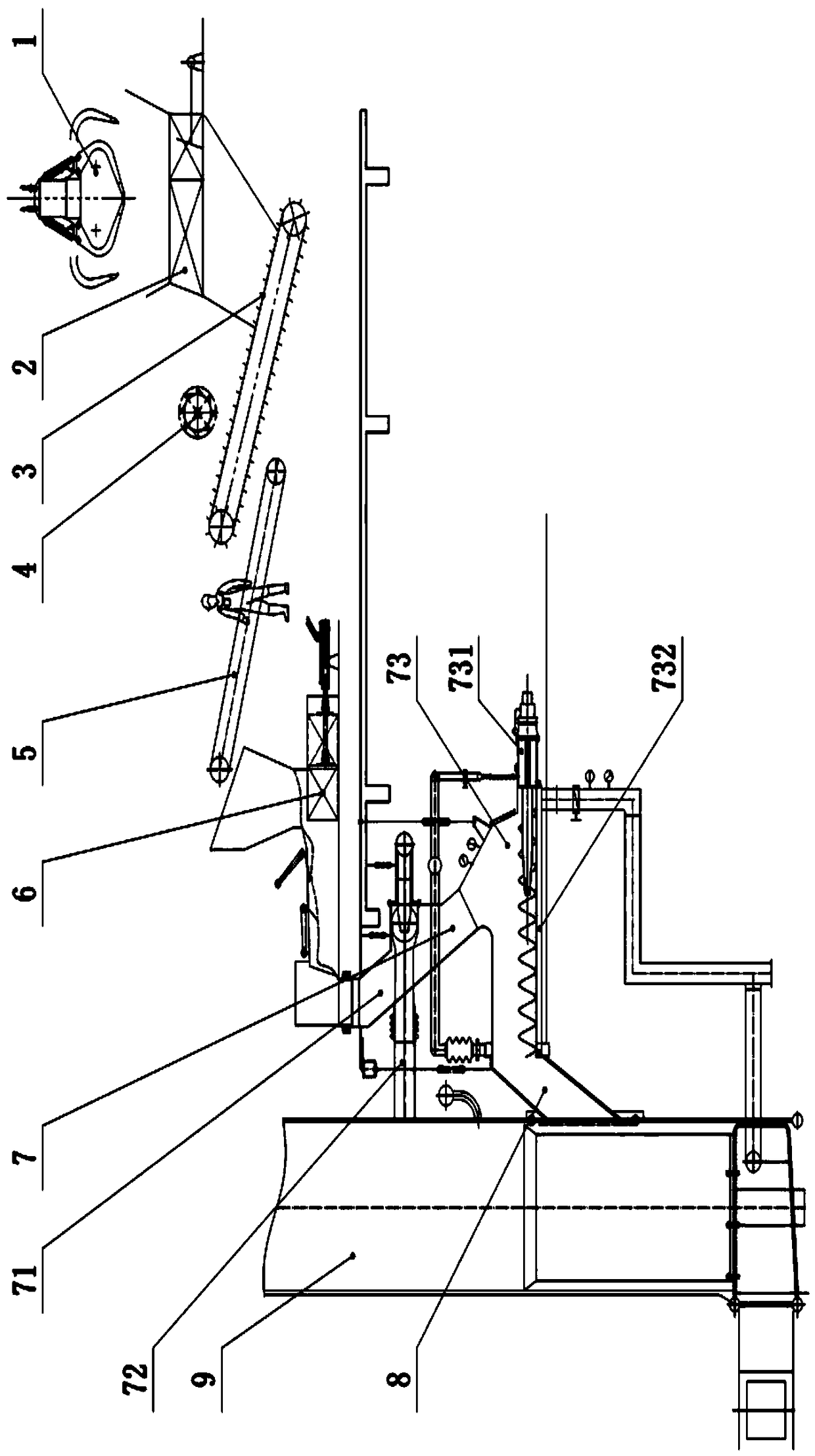

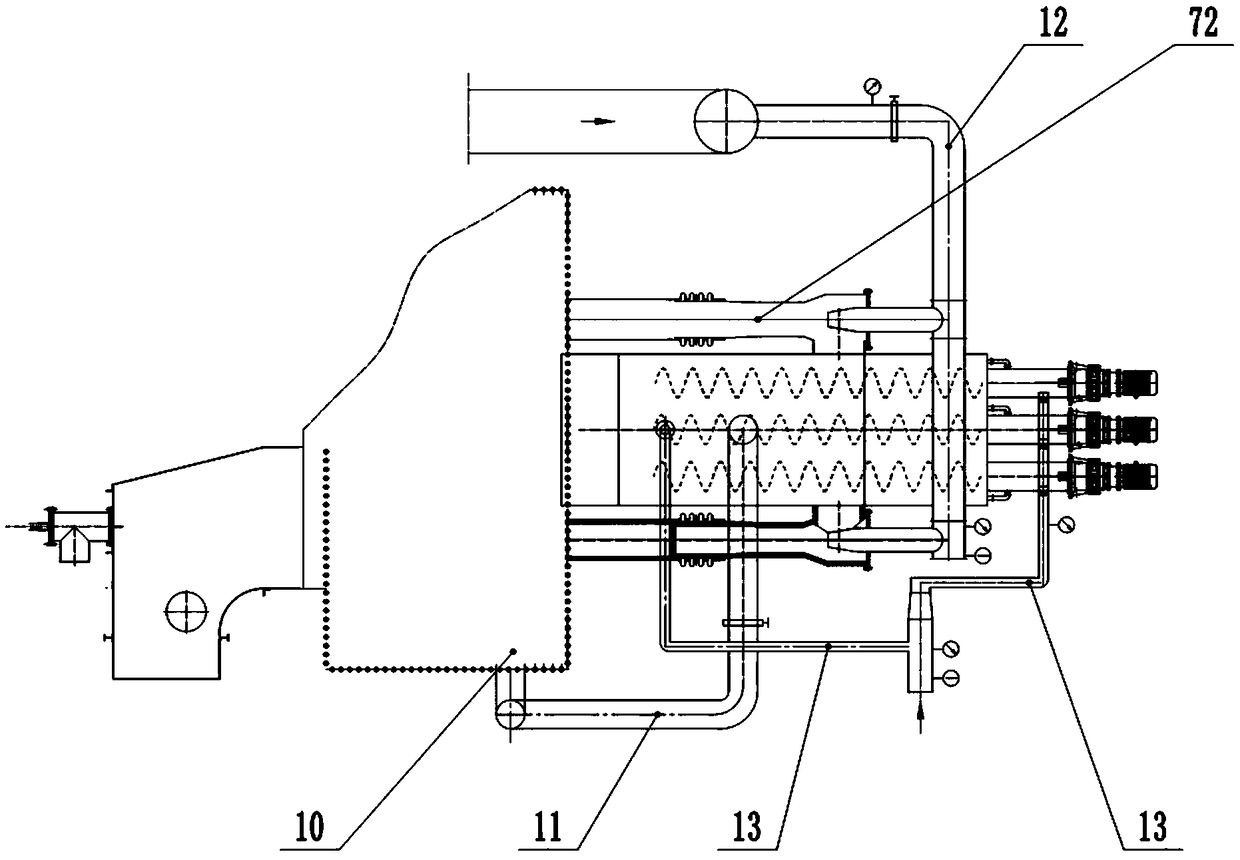

[0055] In order to make the above objects, features and advantages of the invention more obvious and understandable, the embodiments of the invention will be described in detail below in conjunction with the accompanying drawings.

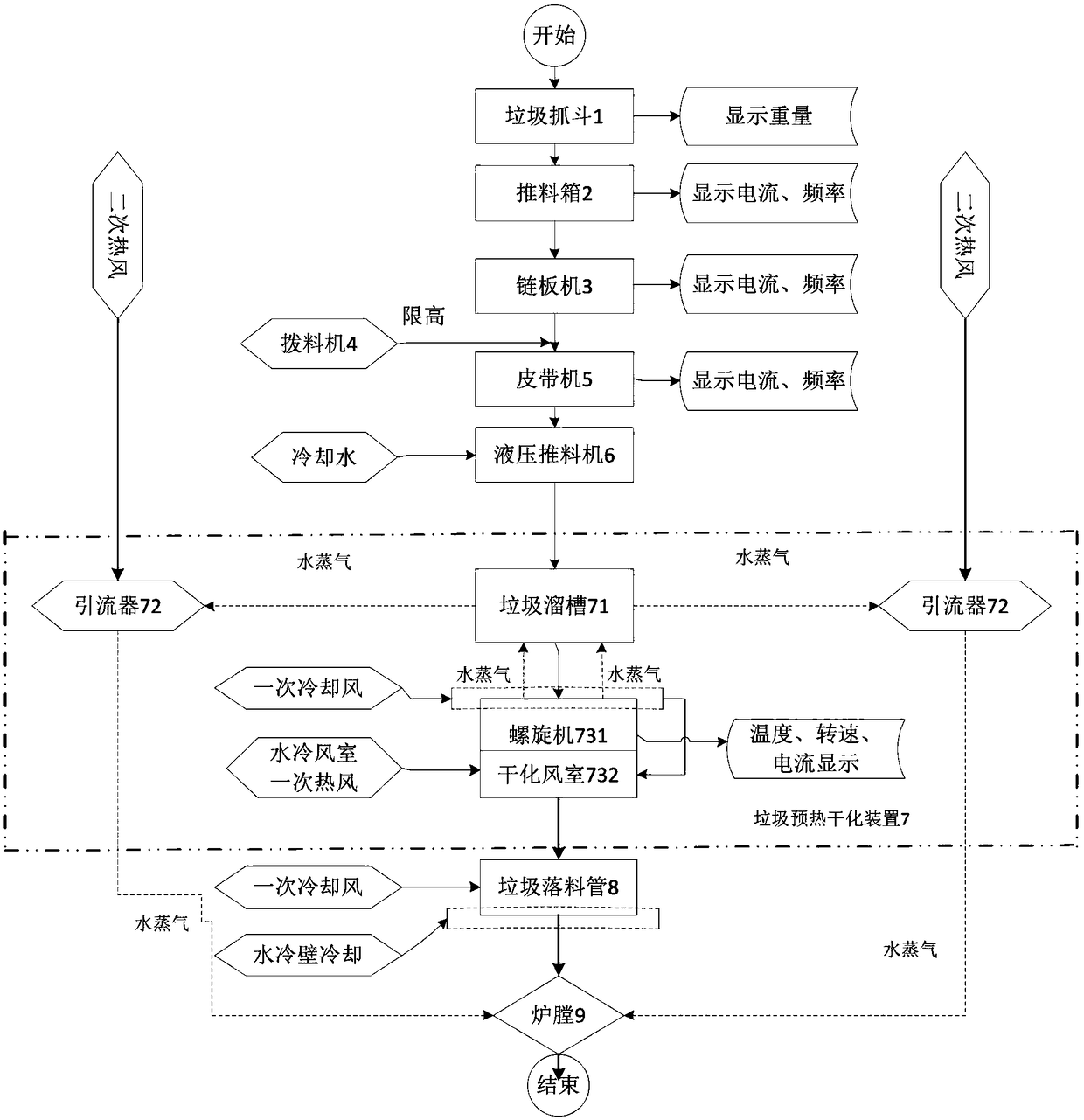

[0056] refer to figure 1 , figure 1 It is a process flow chart of garbage preheating and drying based on the garbage preheating and drying device of the embodiment of the present invention.

[0057] From figure 1 It can be seen that in the garbage preheating and drying device of this embodiment, the furnace feeding system is basically composed of: the garbage material is sent to the push box 2 through the garbage grab 1 . The garbage materials entering the pusher box 2 are sent to the hydraulic pusher 6 through the chain plate machine 3, the feeder 4, and the belt conveyor 5 successively. Specifically, the untreated domestic waste is piled up, fermented and dehydrated in the waste warehouse, and then grabbed by the garbage grab 1 and put into th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com