Method for realizing grease accumulation of microalgae on basis of waste molasses-alcohol mash culture

A technology of molasses alcohol and waste mash, applied in the direction of microorganism-based methods, biochemical equipment and methods, microorganisms, etc., can solve the problems of accumulation of oil, low biomass yield and high-quality yield, and achieve energy saving, oil Content and biomass increase, the effect of protecting the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] (1) Preparation of medium: Gradiently dilute the waste mash 1600 times, as the Monoraphidium sp. FXY-10 basal medium, then add MgSO to the basal medium 4 ·7H 2 O: dosage 182.2mg / L; adjust the pH value to 6.8-7.0;

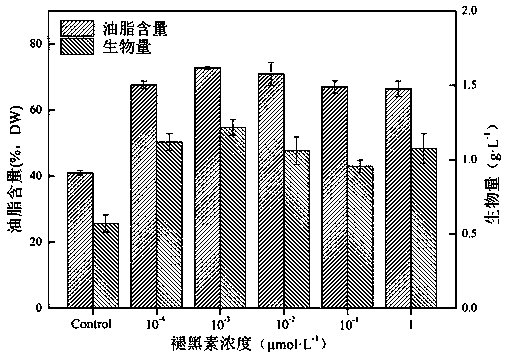

[0026] (2) Cultivation of oleaginous microalgae: sterilize under high pressure and high temperature for 20 minutes, insert Monopodella oleaginum, and control the algae cell density at 10 6 Melatonin was added to the culture medium so that the final melatonin concentration was 1 μmol / L, the light culture temperature was 25°C, the light intensity was 3500 lux, and the shaker speed was 150 r / min, and light shake flask culture was carried out.

[0027] (3) Preparation of biodiesel: enrich the microalgae cultured to the stable stage, centrifuge at 3500r / min for 10min, wash twice with distilled water and freeze-dry; add 2 times the weight of freeze-dried algae powder Quartz sand was ground for 20 minutes and oil was extracted with chloroform-methanol with a vol...

Embodiment 2

[0030] (1) Preparation of culture medium: the waste mash was diluted 1550 times, as the Monoraphidium sp. FXY-10 basal medium, then add MgSO to the basal medium 4 ·7H 2 O: dosage 176.5mg / L; adjust the pH value to 6.8-7.0;

[0031] (2) Cultivation of oleaginous microalgae: sterilize under high pressure and high temperature for 20 minutes, insert Monopodella oleaginum, and control the algae cell density at 1.2×10 6 cells / ml, add melatonin to the culture medium so that the final melatonin concentration is 10 -3 μmol / L, the light culture temperature is 23°C, the light intensity is 4000 lux, and the shaker speed is 130r / min, and light shake flask culture is carried out.

[0032] (3) Preparation of biodiesel: enrich the microalgae cultured to the stable stage, centrifuge at 3500r / min for 10min, wash twice with distilled water and freeze-dry; add 2 times the weight of freeze-dried algae powder Quartz sand was ground for 20 minutes and oil was extracted with chloroform-methanol w...

Embodiment 3

[0035] (1) Preparation of medium: Gradiently dilute the waste mash 1650 times, as the Monoraphidium sp. FXY-10 basal medium, then add MgSO to the basal medium 4 ·7H 2 O: dosage 187.5mg / L; adjust the pH value to 6.8-7.0;

[0036](2) Cultivation of oleaginous microalgae: sterilize under high pressure and high temperature for 20 minutes, then insert Monopodella oleaginum, and control the algae cell density at 1.5×10 6 cells / ml, add melatonin to the culture medium so that the final melatonin concentration is 10 -4 μmol / L, light culture temperature is 26°C, light intensity is 2500 lux, shaker speed is 160r / min, and light shake flask culture is carried out.

[0037] (3) Preparation of biodiesel: enrich the microalgae cultured to the stable stage, centrifuge at 3500r / min for 10min, wash twice with distilled water and freeze-dry; add 2 times the weight of freeze-dried algae powder Quartz sand was ground for 20 minutes and oil was extracted with chloroform-methanol with a volume r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxygen consumption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com