Waterborne titanium white paste and preparation method thereof

A white paste, water-based technology, applied in the direction of pigment paste, etc., can solve the problems of poor compatibility of color paste, high VOC content, poor stability of color paste, etc., to achieve good compatibility, improve coloring degree, and enhance stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

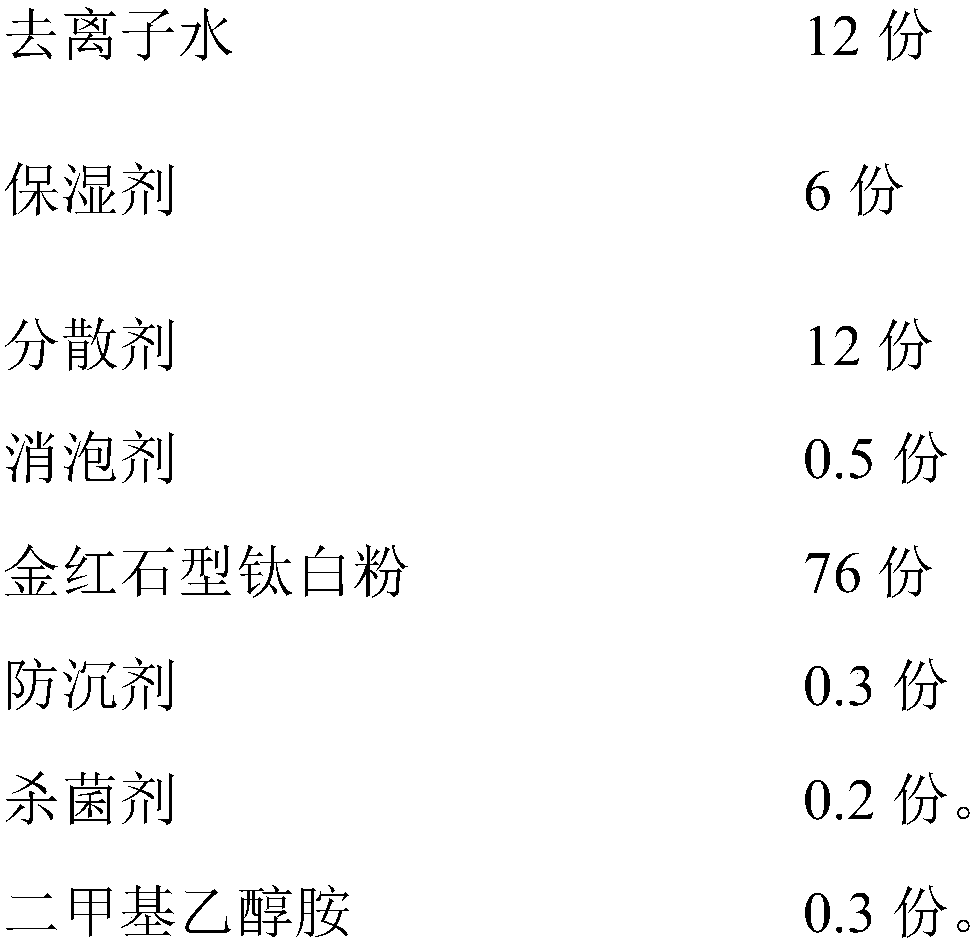

[0031] An embodiment of the present invention provides a water-based titanium white slurry, which comprises the following raw material components in parts by weight:

[0032]

[0033] The above humectants are Humectant 7000; the dispersant is Dispers 755W; defoamer is Foamex 830; rutile titanium dioxide is DuPont R706; anti-sedimentation agent is Luvogel W2N produced by Leifusi Company; fungicide is produced by Troy Company K9N.

[0034] The preparation steps of above-mentioned water-based titanium white slurry are as follows:

[0035] Add deionized water, humectant, dispersant, and defoamer to the material preparation pot in sequence, control the speed at 400r / min, disperse for 10 minutes, increase the speed to 800r / min, slowly add rutile titanium dioxide, anti-sedimentation agent, and adjust the speed 1000r / min, disperse for 20min, grind to fineness ≤ 10μm, then add fungicide under stirring at 400r / min, adjust pH value to 7.5 with dimethylethanolamine, and obt...

Embodiment 2

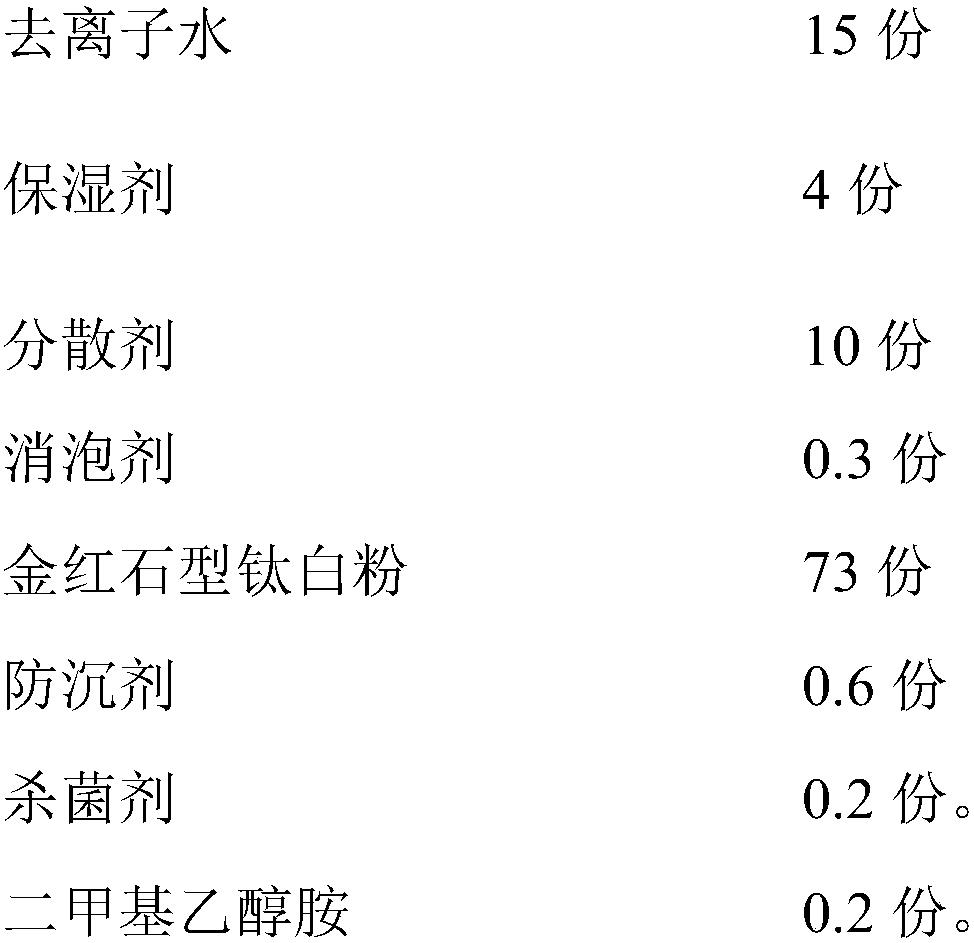

[0037] An embodiment of the present invention provides a water-based titanium white slurry, which comprises the following raw material components in parts by weight:

[0038]

[0039] The above humectants are Humectant 7000; the dispersant is Dispers 755W; defoamer is Foamex 830 and A mixture of Foamex 833, the Foamex 830 and The mass ratio of Foamex 833 is 1:1; the rutile titanium dioxide is DuPont R706; the anti-sedimentation agent is Luvogel W2N produced by Leifusi Company; the fungicide is produced by Troy Company K9N.

[0040] The preparation steps of above-mentioned water-based titanium white slurry are as follows:

[0041] Add deionized water, humectant, dispersant, and defoamer to the material preparation pot in sequence, control the speed at 500r / min, disperse for 15 minutes, increase the speed to 700r / min, slowly add rutile titanium dioxide, anti-sedimentation agent, and adjust the speed 900r / min, disperse for 30min, grind to fineness ≤ 10μm, th...

Embodiment 3

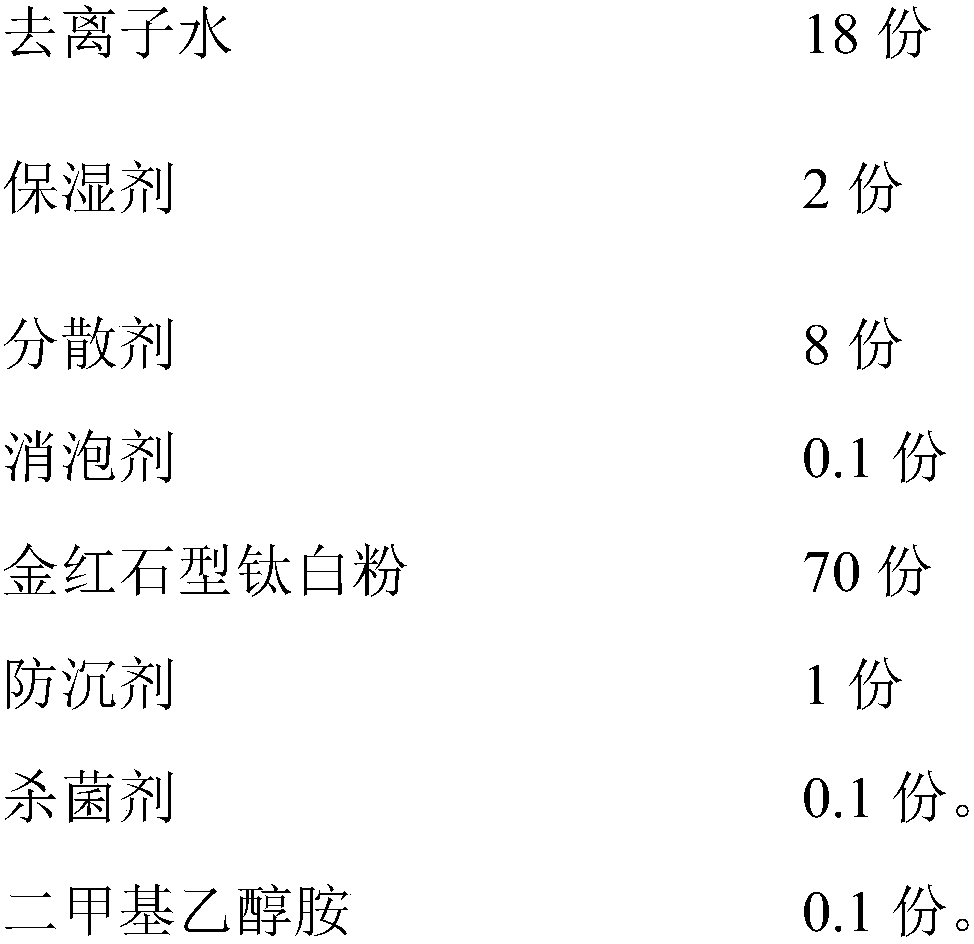

[0043] An embodiment of the present invention provides a water-based titanium white slurry, which comprises the following raw material components in parts by weight:

[0044]

[0045] The above humectants are Humectant 7000; the dispersant is Dispers 755W; defoamer is Foamex 833; rutile titanium dioxide is DuPont R706; anti-sedimentation agent is Luvogel W2N produced by Leifusi Company; fungicide is produced by Troy Company K9N.

[0046] The preparation steps of above-mentioned water-based titanium white slurry are as follows:

[0047] Add deionized water, humectant, dispersant, and defoamer to the material preparation pot in sequence, control the speed at 600r / min, disperse for 30min, increase the speed to 600r / min, slowly add rutile titanium dioxide, anti-sedimentation agent, and adjust the speed 800r / min, disperse for 40min, grind to fineness≤10μm, then add fungicide under stirring at 600r / min, adjust pH value to 8.0 with dimethylethanolamine, and obtain aque...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com