Low rolling resistance tire rubber composition and application thereof

A rubber composition and low rolling resistance technology, applied in the field of tire rubber, can solve the problems of hysteresis loss, unfavorable tire rolling resistance, inability to take into account, conflicting wear resistance, etc., to improve tire rolling resistance, processing workability, and grip. And the effect of good wear resistance and difficult processing workability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0050] The specific preparation process in the embodiment of the present invention is divided into three stages: the first stage, raw rubber, reinforcing filler and plasticizing system are added in proportion, and the mixing temperature is preferably 140-160°C; the second stage (re-mixing stage), zinc oxide, stearic acid, anti-aging agent, etc. are added in proportion, and the kneading temperature is preferably 140-160°C. In the final mixing stage, accelerators and sulfur are added, and the mixing temperature is preferably 90-115°C. After kneading, the embodiment of the present invention is subjected to a vulcanization step: vulcanize the unvulcanized rubber composition under pressure for 20 minutes at 160° C. to obtain a vulcanized rubber composition.

[0051] In addition, the present invention also provides the use of the low rolling resistance tire rubber composition as described above as a tire tread. Among them, the present invention has no special restrictions on tire t...

Embodiment 1

[0056] According to the components shown in Table 1, use a general Banbury internal mixer to prepare in a step-by-step mixing manner. In the first stage, raw rubber, reinforcing filler and plasticizing system are added in proportion, and the mixing temperature is 150°C. In the re-mixing stage, zinc oxide, stearic acid, anti-aging agent, etc. are added in proportion, and the mixing temperature is 150°C. In the final mixing stage, accelerator and sulfur are added, and the mixing temperature is 105°C.

[0057] After kneading, the unvulcanized rubber composition was vulcanized under pressure at 160° C. for 20 minutes to obtain a vulcanized rubber composition.

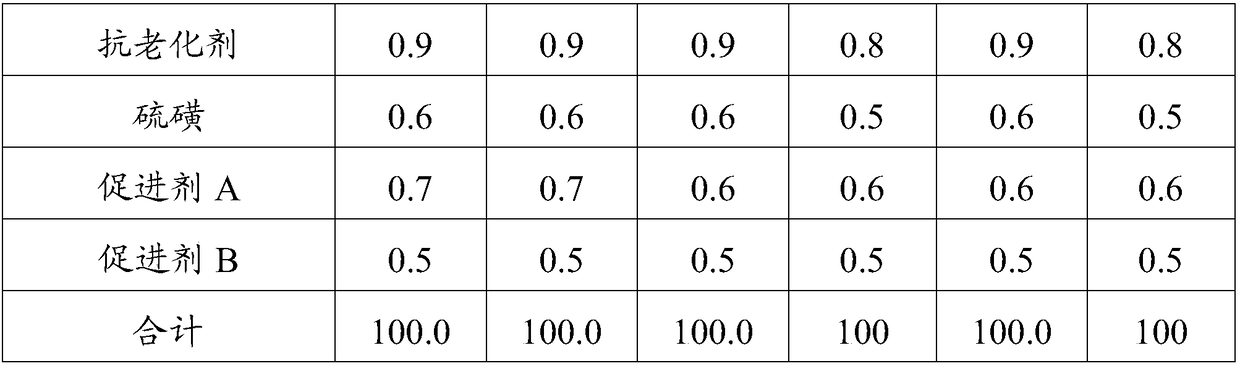

[0058] Table 1 Comparative Examples 1-2 of the present invention and the components of Examples 1-4 and their contents (numerical unit: % by weight)

[0059]

[0060]

Embodiment 2~4

[0062] According to the components shown in Table 1, the same method as in Example 1 was used to knead separately to obtain films.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com