Small molecule gelling factor, gel material, preparation method and application

A small-molecule gel and gel material technology, applied in the field of gel materials, can solve the problems of complex preparation methods, high cost, and long gelation time of small-molecule gel factors, and achieve good recycling and low preparation costs , the effect of simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] A preparation method of small molecule gelling factor:

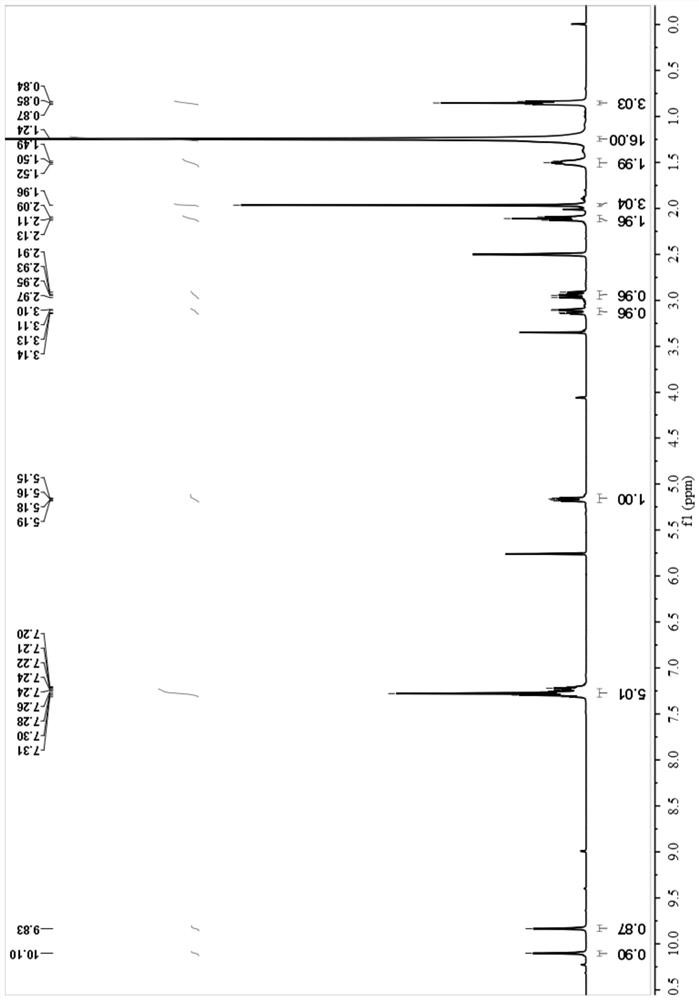

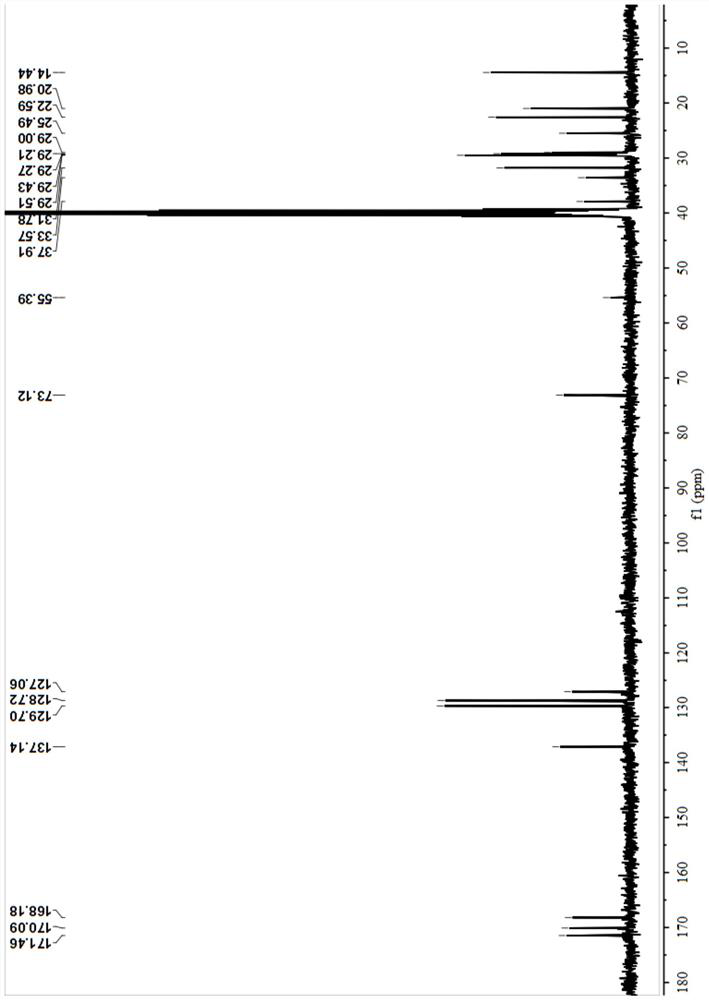

[0046] In this embodiment, the following reaction is used to prepare the multifunctional small molecule gelling factor shown in formula I, wherein R is C 11 straight-chain alkyl of:

[0047]

[0048] The specific preparation process is:

[0049] 1) 2-acetoxyphenylpropionic acid shown in the synthetic formula II

[0050] Under nitrogen protection, dissolve 8.3 g of L-phenyllactic acid in 14 ml of dry pyridine, stir in an ice bath for 10 minutes, add 14.5 ml of acetic anhydride dropwise to the above solution, and react at room temperature for 6 hours (monitored by thin-layer chromatography until the reaction is complete) ), add 40ml of dichloromethane to dilute the above reaction solution, wash with 40ml of 1mol / L hydrochloric acid solution, separate the organic phase and dry with anhydrous sodium sulfate, and spin off the organic solvent under reduced pressure to obtain 9.4g of colorless oil, with a yield of abo...

Embodiment 2

[0061] In this embodiment, the following reaction is used to prepare the multifunctional small molecule gelling factor shown in formula I, wherein R is C 5 straight-chain alkyl of:

[0062]

[0063] The specific preparation process is:

[0064] 1) Synthesis of 2-acetoxyphenylpropionic acid shown in formula II: the same as in Example 1, and will not be repeated here.

[0065] 2) the hydrazide shown in the synthetic formula III

[0066] Under the protection of nitrogen, add 3.7g of methyl hexanoate into a reaction flask containing 45ml of ethanol, add 5.6ml of hydrazine hydrate under stirring at room temperature, raise the temperature to 80°C, and react for 5 hours. After the reaction, cool to room temperature and stir overnight, and filter with suction 3.3 g of white solid was obtained, the yield was about 90%.

[0067] 3) Synthesizing the small molecule gelling factor shown in formula I

[0068] Under nitrogen protection, dissolve 1.04 g of 2-acetoxyphenylpropionic acid...

Embodiment 3

[0070] In this embodiment, the following reaction is used to prepare the multifunctional small molecule gelling factor shown in formula I, wherein R is C 15 straight-chain alkyl of:

[0071]

[0072] The specific preparation process is:

[0073] 1) Synthesis of 2-acetoxyphenylpropionic acid shown in formula II: the same as in Example 1, and will not be repeated here.

[0074] 2) the hydrazide shown in the synthetic formula III

[0075] Under the protection of nitrogen, add 7.6g of methyl palmitate into a reaction flask containing 80ml of ethanol, add 5.6ml of hydrazine hydrate under stirring at room temperature, raise the temperature to 80°C, and react for 8 hours. After the reaction, cool to room temperature and stir overnight, and filter with suction 6.1 g of white solid was obtained, about 81% yield.

[0076] 3) Synthesizing the small molecule gelling factor shown in formula I

[0077] Under nitrogen protection, dissolve 1.04 g of 2-acetoxyphenylpropionic acid repres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com