A kind of preparation method of biomass carbon material doped with molybdenum phosphide nanoparticles with pore network structure

A biomass carbon and nanoparticle technology, applied in chemical instruments and methods, water pollutants, other chemical processes, etc., can solve the problems of cumbersome preparation process, high cost, unfavorable production and preparation, etc., and achieve simple preparation process and easy separation. , the effect of reducing the burden on the marine environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] An in-situ conversion preparation method of a molybdenum phosphide-doped biomass-carbon composite material with a pore network structure is characterized in that it is prepared from Enteromorpha as a biomass carbon source, and is mainly prepared from the following raw materials in parts by weight become:

[0046] 1 part dried Enteromorpha, 1 part sodium hypochlorite, 1 part glacial acetic acid, 1 part ammonium molybdate.

[0047] The in-situ conversion preparation method of a kind of biomass carbon-based composite material of the present invention comprises the following steps:

[0048] (1) The salvaged Enteromorpha enteromorpha was rinsed with water, dried in a vacuum oven at 80°C, and set aside.

[0049] (2) Place the dried Enteromorpha in acidified sodium hypochlorite solution for decolorization, specifically, take 10g of dried Enteromorpha and soak it in 200mL acidified sodium hypochlorite solution (the solution kind contains 1.5mL of glacial acetic acid and 1.99g ...

Embodiment 2

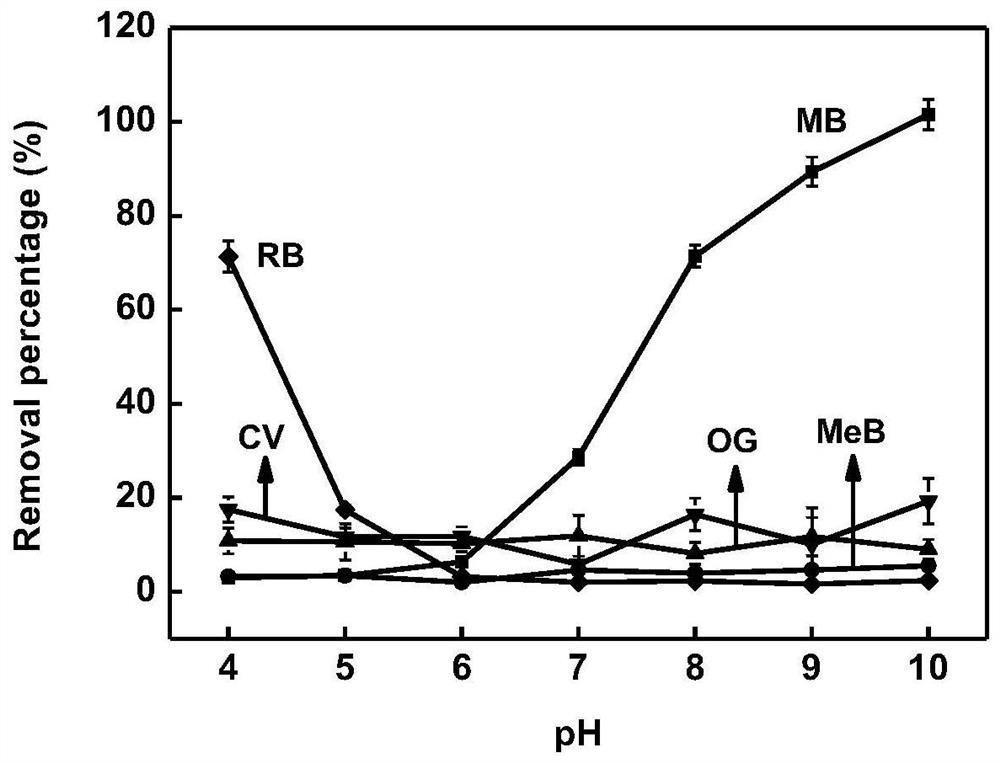

[0053] Weigh 2mg of MoP / HPC composite material, add 1.0mL model dye solution (100mg L -1 , pH4~10), the mixture was centrifuged at 2000rpm for 2min after shaking and adsorption for 5min, and the supernatant was collected for quantitative analysis of the residual dye in the initial solution. The test was carried out on a U3900 ultraviolet-visible spectrometer, and the characterization results are as follows figure 2 shown.

Embodiment 3

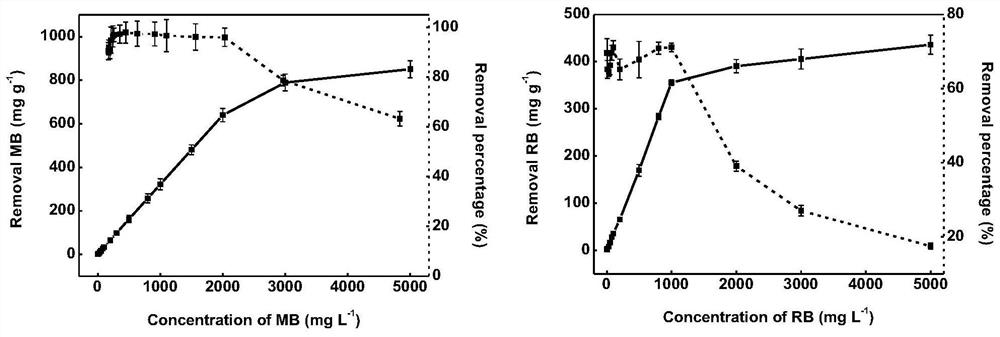

[0055] Weigh 2mg of MoP / HPC composite material, add 1.0mL methylene blue solution (MB) (5~5000mgL -1 , pH 10.0) and 1.0mL Rose Bengal (RB) (5~5000mg L -1 , pH 10.0), the mixture was centrifuged at 2000rpm for 2min after shaking and adsorption for 5min, and the supernatant was collected for quantitative analysis of the residual dye in the initial solution. The test was carried out on a U3900 ultraviolet-visible spectrometer, and the characterization results are as follows image 3 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com