Novel fermenting bed device and fertilizer fermenting method

A fermentation bed and a new type of technology, applied in the field of ectopic fermentation bed and fertilizer fermentation, can solve the problems of unfavorable fermentation, increased labor cost, harsh working environment of workers, etc., reduce power consumption and equipment cost, improve fermentation efficiency and effect, The effect of improving the working environment on site

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

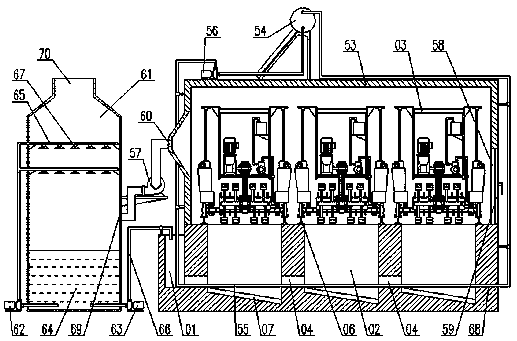

[0038] Example 1: A new type of fermenter fermentation method of the fermentation bed device, the fermentation method is as follows:

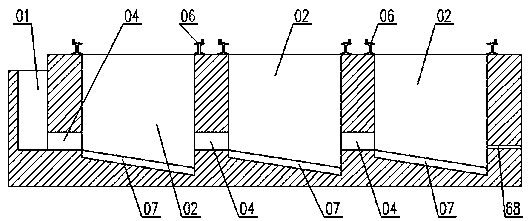

[0039] a. Addition of excrement and urine: according to the weight ratio, 140 kilograms of excrement and urine in the septic tank are sucked into the storage ditch 01 through the first-stage pump, and the excrement and urine in the storage ditch 01 flows from the trough 04 In the fermentation tank 02, the feces and urine can be pig feces and urine;

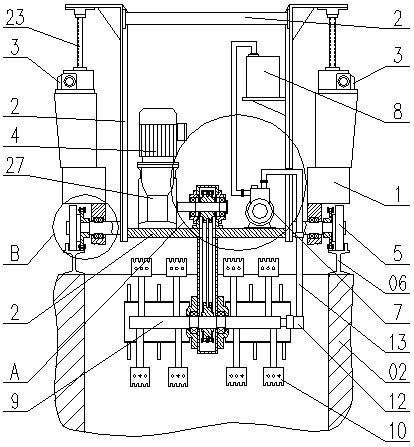

[0040] b. Addition of substrate bedding: take the following substrate bedding according to the weight ratio: 80 kg of bran, 40 kg of sawdust and 60 kg of crop stalks. Among them, corn stalks can be used for crop stalks, and the substrate bedding can be crushed to particle size The 10 mesh powder is fully mixed and evenly mixed to make a mixed powder. The mixed powder is evenly spread in the bottom of the fermentation tank 02, and the mixed powder and feces are fully absorbed to form a pile, and then tur...

Embodiment 2

[0042] Example 2: A new type of fermentation bed device fertilizer fermentation method, the fermentation method is as follows:

[0043] a. Addition of excrement and urine: according to the weight ratio, 145 kg of excrement and urine in the septic tank will be sucked into the storage ditch 01 through a first-stage pump, and the excrement and urine in the storage ditch 01 will flow from the trough 04 In the fermentation tank 02, the feces and urine can be pig feces and urine;

[0044] b. Addition of substrate bedding: take the following substrate bedding according to the weight ratio: 85 kg of bran, 45 kg of sawdust and 65 kg of crop stalks. Among them, corn stalks can be used for crop stalks, and the substrate bedding can be crushed to particle size The 20 mesh powder is mixed thoroughly to make a mixed powder, and the mixed powder is evenly spread in the bottom of the fermentation tank 02, and the mixed powder and feces and urine are fully absorbed to form a pile, and then turned t...

Embodiment 3

[0046] Example 3: A new type of fermentation bed device fertilizer fermentation method, the fermentation method is as follows:

[0047] a. Addition of excrement and urine: according to the weight ratio, 150 kilograms of excrement and urine in the septic tank are sucked into the storage ditch 01 through the first-stage pump, and the excrement and urine in the storage ditch 01 flows from the trough 04 In the fermentation tank 02, the feces and urine can be pig feces and urine;

[0048] b. Addition of substrate litter: take the following substrate litter according to the weight ratio: 90 kg of corn bran, 50 kg of sawdust and 70 kg of crop straw. The crop straw can be corn stalks, and the substrate pad is crushed to particle size The powder is 30 meshes and is fully mixed to make a mixed powder. The mixed powder is evenly spread in the bottom of the fermentation tank 02, and the mixed powder and feces and urine are fully absorbed to form a pile, and then turned over The stacker 03 tur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com