Preparation technology of relief oil drop built lamp

A preparation process and oil droplet technology, applied in the field of construction lamps and their preparation technology, can solve the problems of loss of transmission, weak three-dimensional effect of oil droplets, low yield rate, etc., and achieve the effects of strong three-dimensional three-dimensional effect, clear process flow and easy implementation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

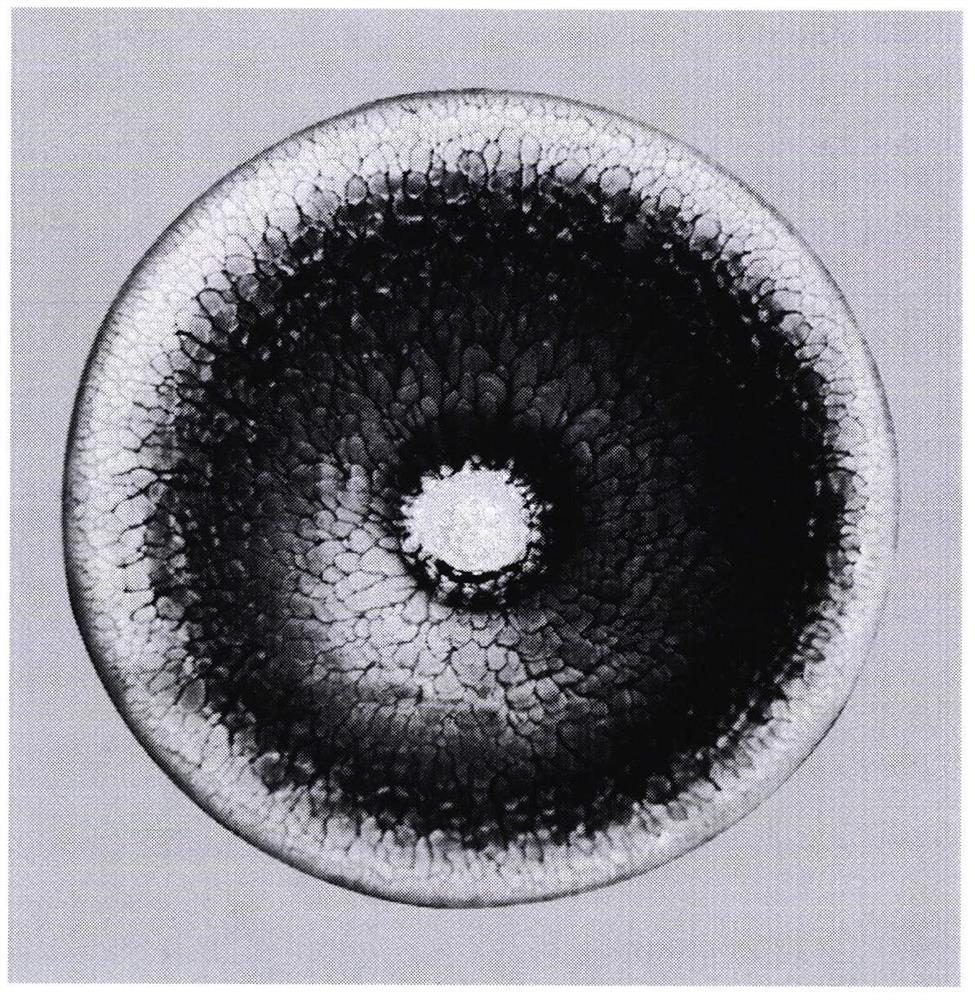

Image

Examples

Embodiment 1

[0030] The embossed oil drop built a lamp, which includes a green body and a glaze; the green body is made of the following components in parts by weight: 8 parts of kaolin and 2 parts of loess; the glaze includes the following components in parts by weight Divided into: 70 parts of glaze stone, 5 parts of plant ash, 10 parts of iron red and 70 parts of water.

[0031] The preparation process of the plant ash is as follows: the following weight components are dried: 9 parts of pine wood, 1.5 parts of rice husk and 0.5 part of Pteris praecox, and then calcined at high temperature to obtain powdery ash, which is ground to 100 mesh.

[0032] The preparation process of the above-mentioned embossed oil droplet construction lamp includes the following steps:

[0033] (1) Weigh and mix the green body raw materials according to the formula, add water, stir with the stirring device for 9 hours, settle for one week, pass through a 90-mesh sieve, drain and stale;

[0034] (2) Pulling, t...

Embodiment 2

[0043] The embossed oil drop built a lamp, which includes a green body and a glaze; the green body is made of the following components in parts by weight: 8 parts of kaolin, 2.2 parts of loess; the glaze includes the following components in parts by weight Divided into: 71 parts of glaze stone, 5.5 parts of plant ash, 9 parts of iron red and 68 parts of water;

[0044] The preparation process of the plant ash is as follows: the following weight components are dried: 10 parts of pine wood, 1.2 parts of rice husk and 0.8 part of Pteris praecox, and then calcined at high temperature to obtain powdery ash, which is ground to 110 mesh.

[0045] The preparation process of the above-mentioned embossed oil droplet construction lamp includes the following steps:

[0046] (1) Weigh and mix the green body raw materials according to the formula, add water, stir with a stirring device for 10 hours, settle for a week, pass through a 100-mesh sieve, filter water, and stale;

[0047] (2) Pul...

Embodiment 3

[0056] Relief oil drop building lamp, which includes body and glaze; the body is made of the following components in parts by weight: 8.5 parts of kaolin, 2.5 parts of loess; the glaze includes the following components in parts by weight Divided into: 73 parts of glaze stone, 5.2 parts of plant ash, 10 parts of iron red and 72 parts of water;

[0057] The preparation process of the plant ash is as follows: mix the following components by weight after drying: 10 parts of pine wood, 1 part of rice husk and 1 part of Pteris vulgaris, calcined at high temperature to obtain powdery ash, and grind the ash to 120 mesh.

[0058] The preparation process of the above-mentioned embossed oil droplet construction lamp includes the following steps:

[0059] (1) Weigh and mix the green body raw materials according to the formula, add water, stir with a stirring device for 10 hours, settle for a week, pass through a 100-mesh sieve, filter water, and stale;

[0060] (2) Pulling, trimming, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com