Oily sludge cleaning method

A technology of oil sludge and cleaning agent, which is applied in chemical instruments and methods, sludge treatment, water/sludge/sewage treatment, etc., and can solve the problems of low degree of automation, high work intensity of operators, and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

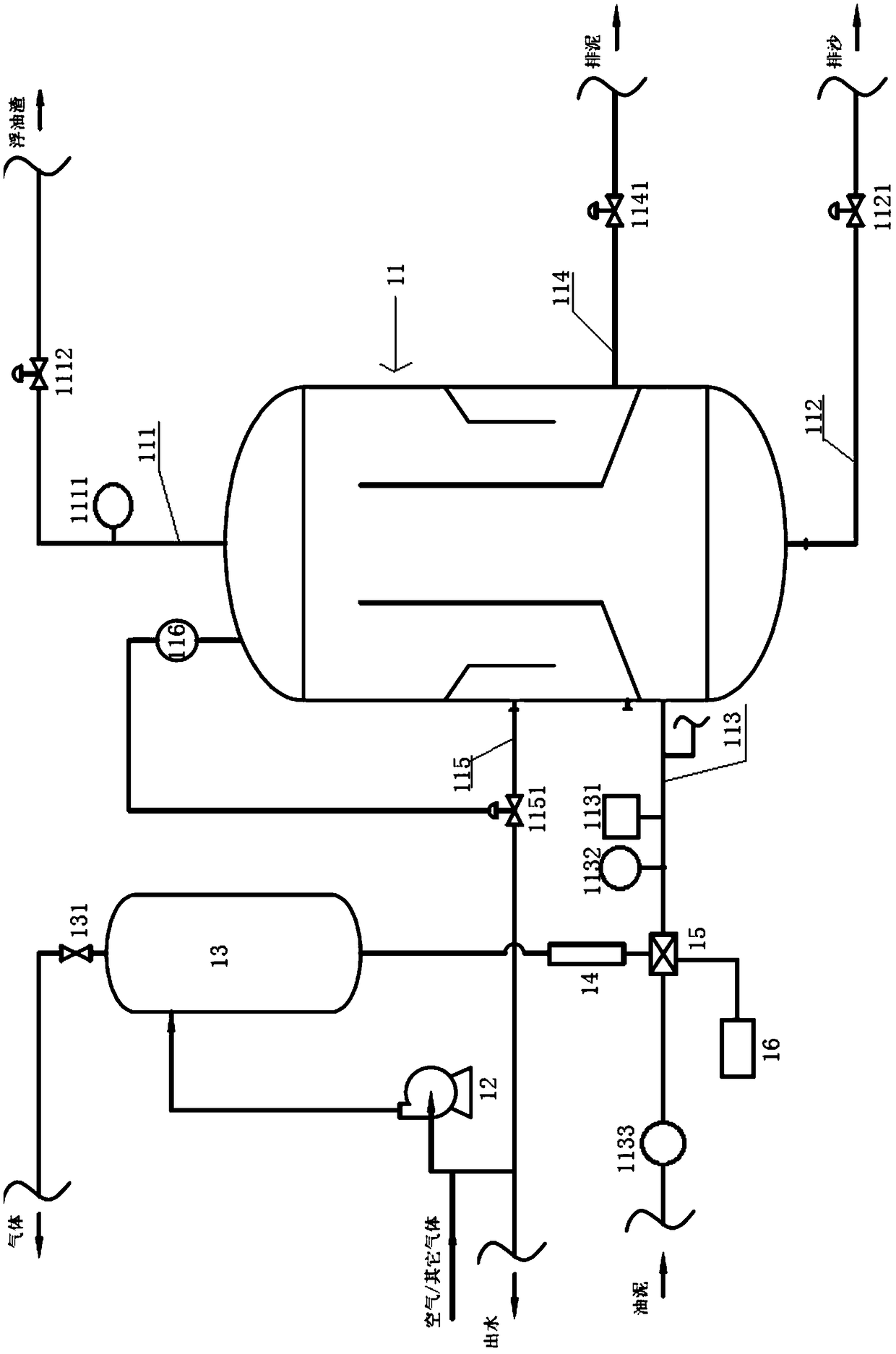

[0045] A micro-nano bubble oil sludge cleaning integrated device, its structure is as follows figure 1 As shown: it includes a cyclone cleaning separation tank 11, a dissolved air pump 12, a stabilization tank 13, a micro-nano bubble release device 14, a cleaning agent adding device 16 and a mixing device 15; the top of the cyclone cleaning separation tank 11 is provided with a floating oil pipe 111, the bottom end of the cyclone cleaning and separation tank 11 is provided with a sand discharge pipe 112, and the side wall of the cyclone cleaning and separation tank 11 is provided with an oil inlet pipe 113, a mud discharge pipe 114 and a drain pipe 115. The dissolved air pump 12 is communicated with the drain pipe 115, and the dissolved air pump 12, the stabilization tank 13 and the micro-nano bubble release device 14 are connected in sequence; the mixing device 15 is arranged on the oil inlet pipe 113 Above; the micronanobubble release device 14 and the cleaning agent adding ...

Embodiment 2

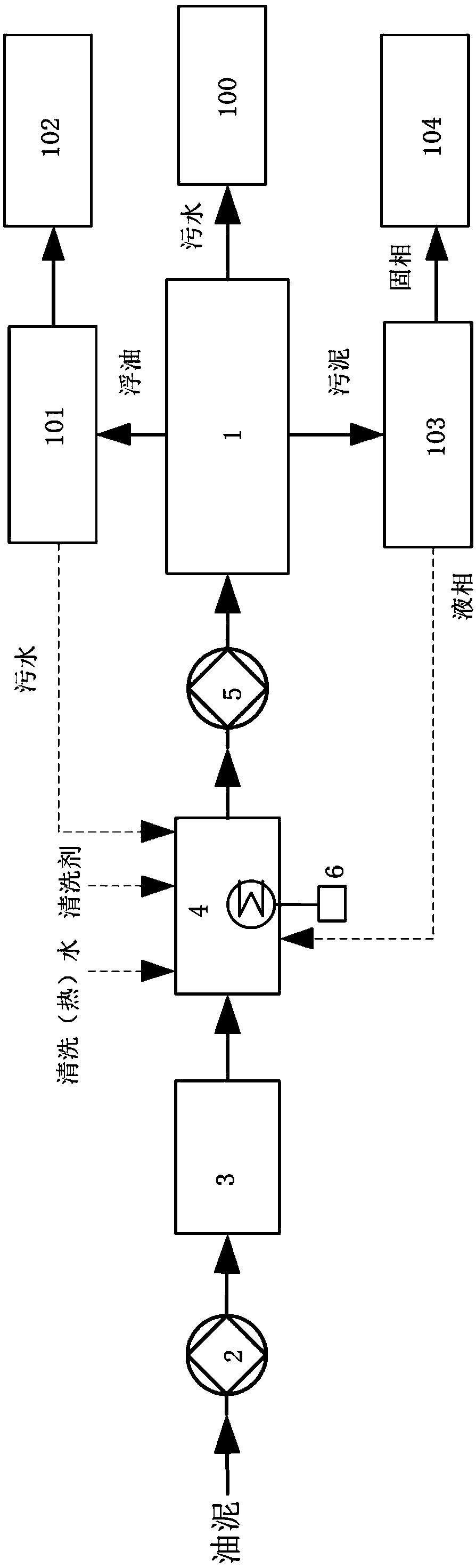

[0048] A sludge cleaning system for non-open air, its structure is as follows figure 2 Shown: including sludge pump 2, filter 3, homogenizing tank 4, screw pump 5, micro-nano bubble sludge cleaning integrated device 1 of the above-mentioned embodiment 1, oil-water separator 101, two-phase centrifuge 103 and sewage advanced treatment device 100; the sludge pump 2, the filter 3, the homogenizing tank 4 and the screw pump 5 are connected in sequence, the screw pump 5 is connected to the sludge inlet pipe 113, and the oil-water separator 101 communicates with the floating oil discharge pipe 111 , the two-phase centrifuge 103 communicates with the mud discharge pipe 114 , and the sewage advanced treatment device 100 communicates with the drain pipe 115 . The oil-water separator 101 is also connected with the dirty oil collection tank 102, the two-phase centrifuge 103 is also connected with the harmless treatment device 104, and the homogenization tank 4 is also equipped with a hea...

Embodiment 3

[0050] A sludge cleaning system for open air, its structure is as follows image 3 Shown: includes a crusher 7, a tempering tank 8, a vibrating screen 9, a homogenizing tank 4, a screw pump 5, the micro-nano bubble sludge cleaning integrated device 1 of the above-mentioned embodiment 1, an oil-water separator 101, and a two-phase centrifuge 103 and sewage advanced treatment device 100; the crusher 7, the tempering tank 8, the vibrating screen 9, the homogenizing tank 4 and the screw pump 5 are connected in sequence, and the screw pump 5 is also connected with the screw pump The oil sludge inlet pipe 113 is connected, the oil-water separator 101 is connected with the oil floating pipe 111, the two-phase centrifuge 103 is connected with the mud discharge pipe 114, and the advanced sewage treatment device 100 is connected with the The drain pipe 115 is connected; the oil-water separator 101 is also connected with the dirty oil collection tank 102, the two-phase centrifuge 103 is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com