S-shaped industrial robot

An industrial robot, snake-shaped technology, applied in the direction of manipulators, manufacturing tools, program-controlled manipulators, etc., can solve the problems of single action, large display space, etc., to achieve the effect of saving space and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

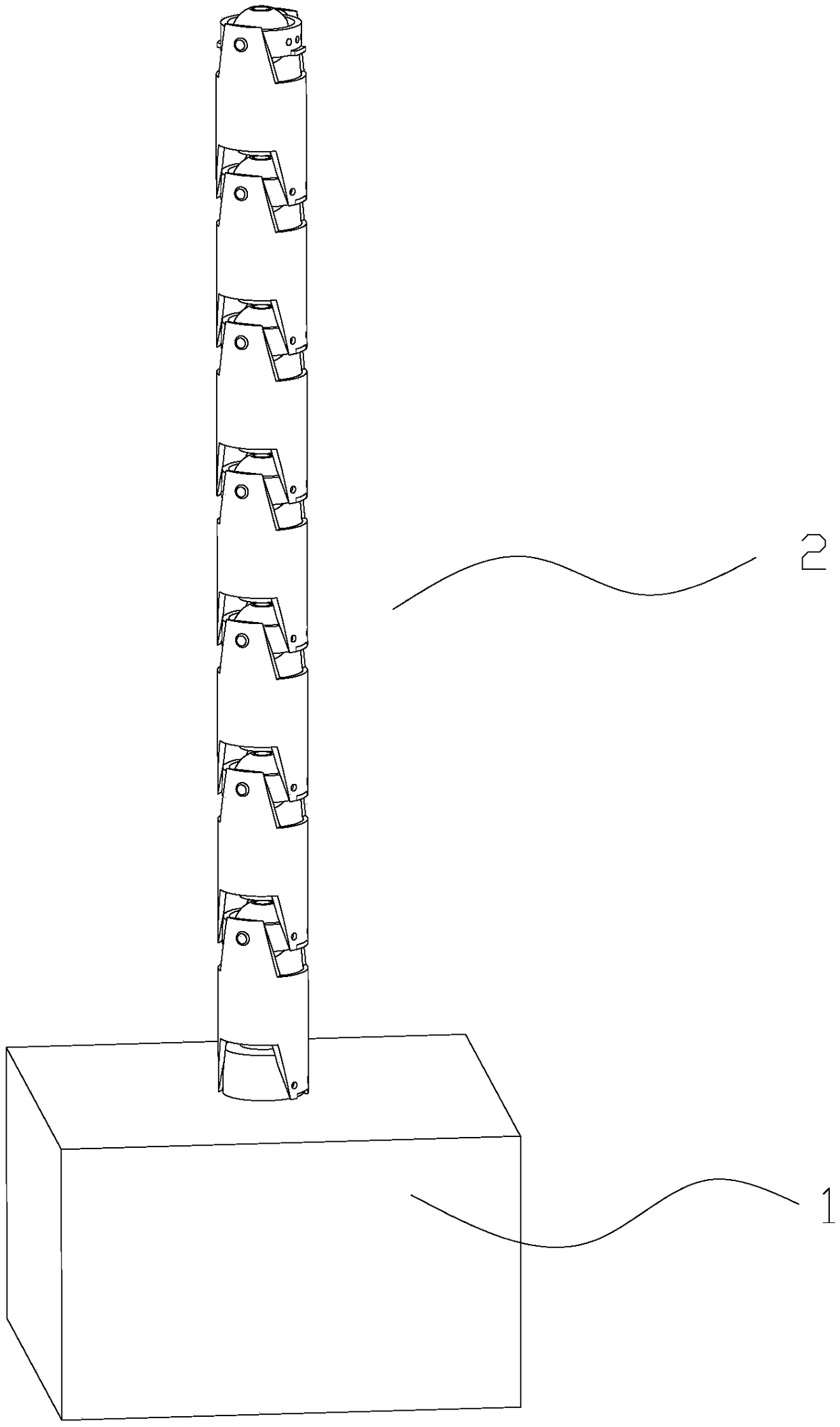

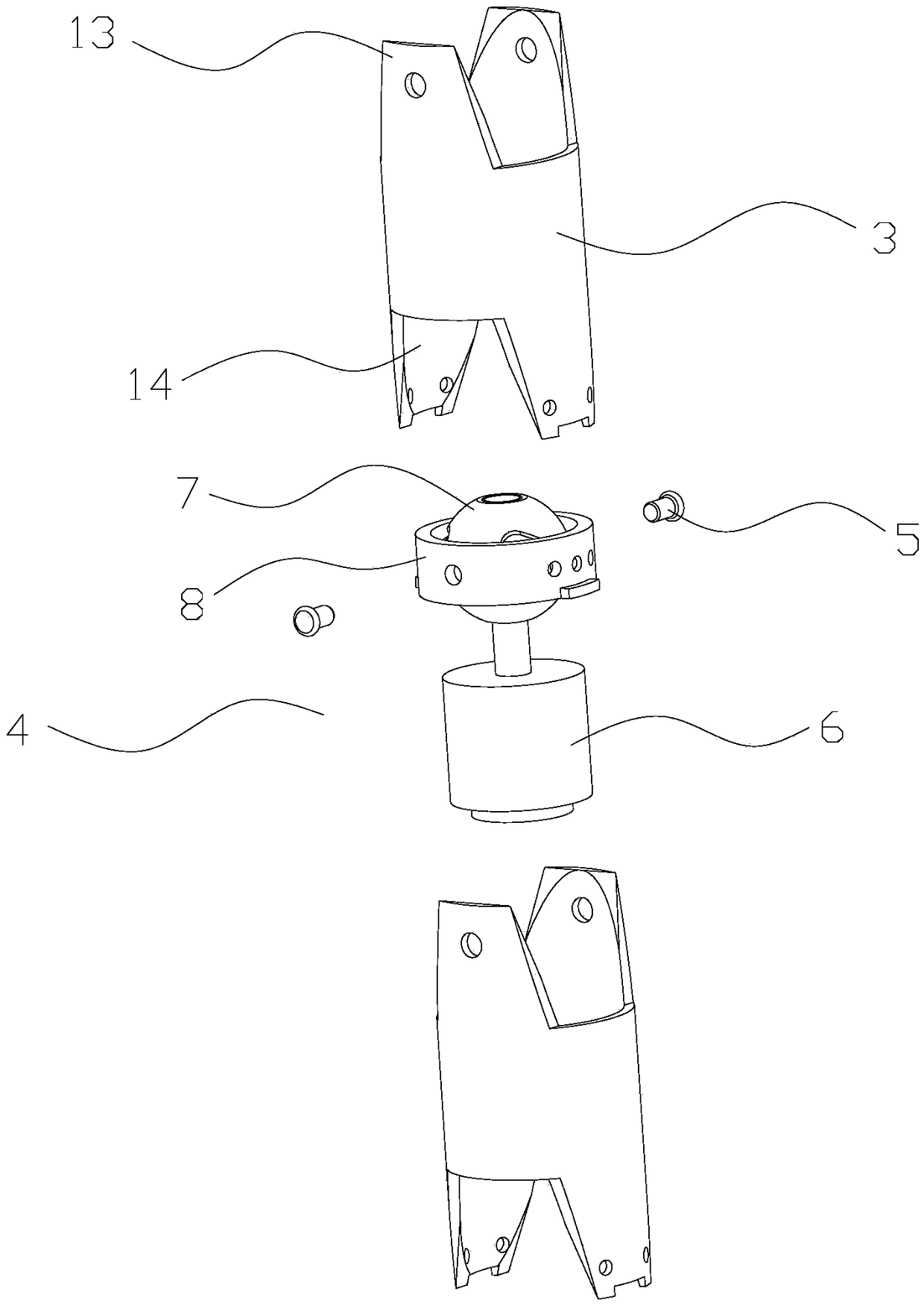

[0043] see Figure 1 to Figure 4 , the present invention discloses a serpentine industrial robot, which includes a base body 1 and a manipulator body 2 installed on the base body 1; wherein, the manipulator body 2 includes a plurality of linked movable sections 3, and between two adjacent movable sections 3 are hinged to each other, and are driven by a joint component 4 located inside the movable joint 3; a control unit is arranged inside the base body 1, and each joint component 4 is controlled and connected to the control unit through a line;

[0044] Joint components 4 are arranged between two adjacent movable joints 3 , and the control unit actually controls the movement of each joint component 4 , thereby controlling the movement of the entire snake-like industrial robot. The arrangement of the connection lines between the joint assembly 4 and the control unit is not specifically limited here, and it is generally laid along the inside of the movable joint 3 . Through the...

Embodiment 2

[0058] The only difference between this embodiment and the first embodiment is that the joint assembly 4 adopts a different structure.

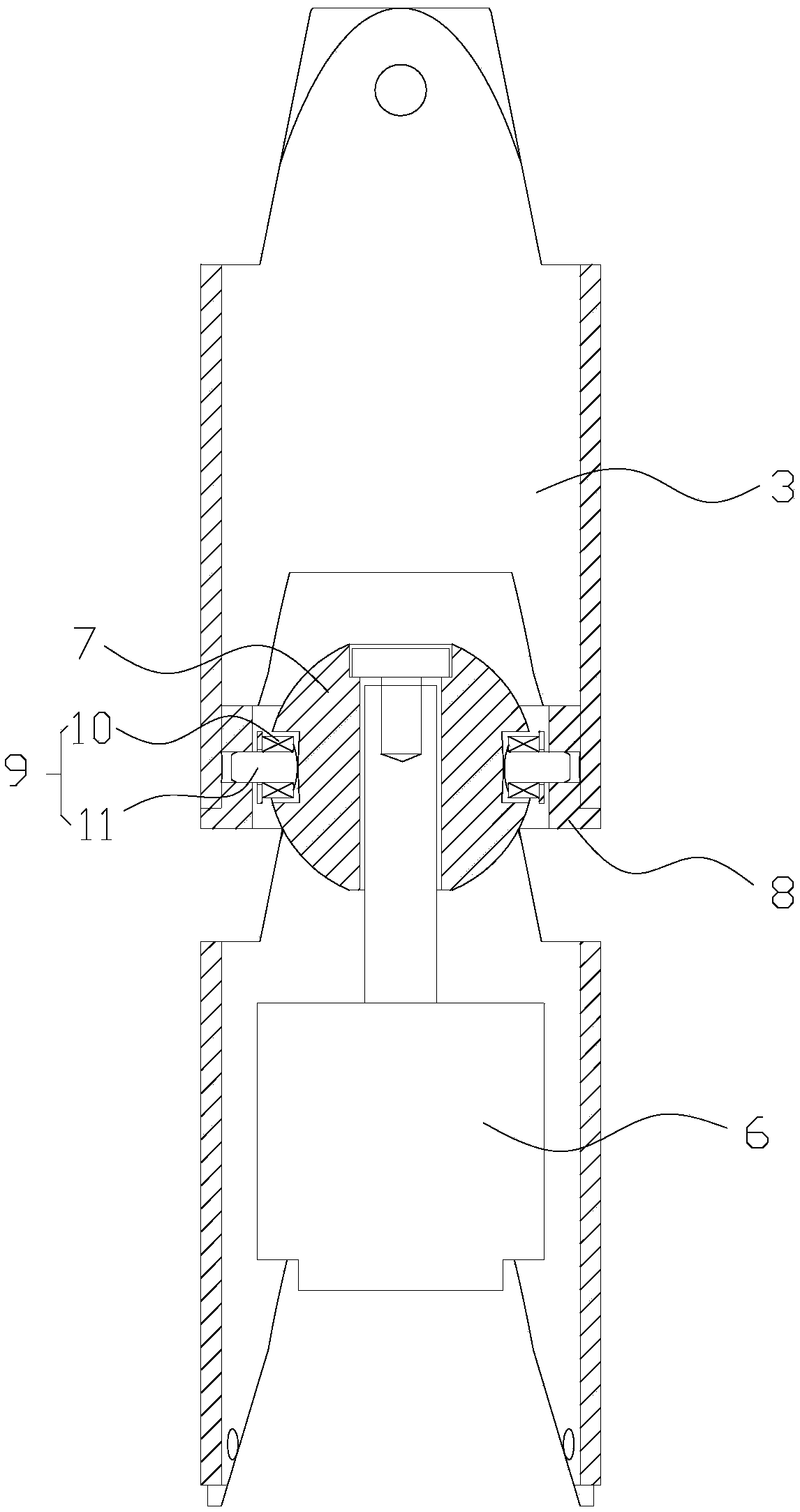

[0059] see Figure 5 to Figure 7 , as preferably, the front and rear sides of the drive member 7 are provided with outwardly protruding drive parts 15; the front and rear sides of the guide member 8 are respectively provided with a first guide rail 16 and a second guide rail 17, one side The first guide rail 16 is arched in the middle part upwards, and the left and right sides protrude downwards, and the second guide rail 17 on the other side is arched in the middle part downwards, and the left and right sides are concave upwards. The two driving parts 15 are respectively in contact with the two guide rails for transmission, so that when the driving member 7 rotates leftward or rightward, the driving part 15 drives the guiding member 8 to rotate left and right.

[0060] In this embodiment, the structures of the driving member 7 and the guidi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com