A polishing and crystallizing cleaning pad for combined stone

A cleaning pad and crystallization technology, applied in metal processing equipment, manufacturing tools, layered products, etc., can solve the problems of damage to stone, easy to cause pollution, high temperature resistance, etc., to achieve the effect of ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0024] As an embodiment of the present invention, in parts by weight, the preparation raw materials for the crystallization and cleaning main material layer at least include: 5-20 parts of polyurethane, 20-25 parts of phenolic resin, 40-50 parts of oxalic acid / oxalate , 6.5-7.5 parts of oxide abrasive, 1-5 parts of surfactant and 1-2 parts of castor oil.

[0025] As an embodiment of the present invention, in parts by weight, the preparation raw materials for the crystallization and cleaning main material layer at least include: 15 parts of polyurethane, 23 parts of phenolic resin, 46.5 parts of oxalic acid / oxalate, and 7.1 parts of oxide abrasive , 2 parts of surfactants and 1.5 parts of castor oil.

[0026] Polyurethane

[0027] The polyurethane is modified polyurethane.

[0028] As a kind of embodiment of the present invention, the preparation method of described modified polyurethane is as follows:

[0029] (1) Diamond modification: at room temperature, put 10g of nano...

Embodiment approach 1

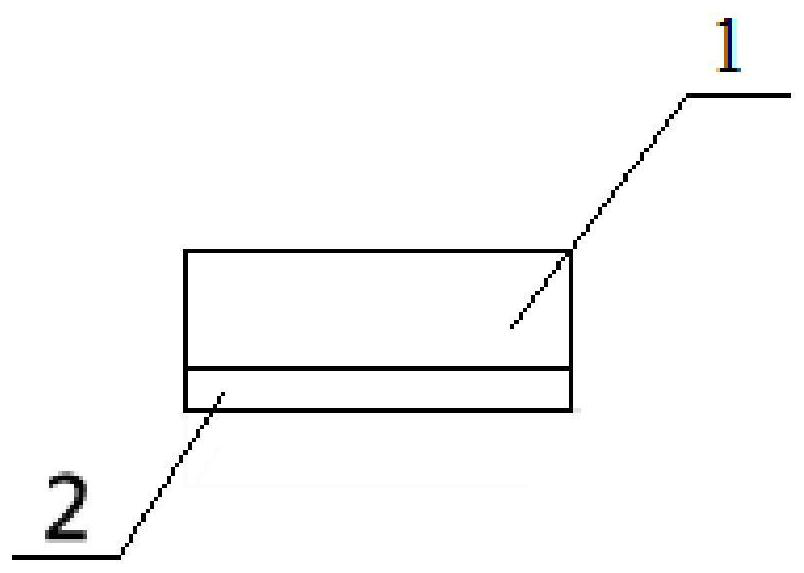

[0061] Embodiment 1. A polishing and crystallization cleaning pad for combined stone materials, the cleaning pad is divided into crystallization, cleaning main material layer and non-woven fabric layer from top to bottom.

Embodiment approach 2

[0062] Embodiment 2. The polishing and crystallization cleaning pad for combined stone materials described in Embodiment 1, the thickness ratio of the crystallization, cleaning main material layer and non-woven fabric layer is (5-15):1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com