Laser trimming forming grinding wheel device and dressing method based on visual detection

A forming grinding wheel and laser trimming technology, which is applied to abrasive surface adjustment devices, grinding/polishing equipment, metal processing equipment, etc., can solve the problems of low dressing efficiency, high processing environment requirements, and high maintenance costs, and achieve equipment maintenance and The effect of low operating cost, high efficiency and high precision automation, quick disassembly and installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

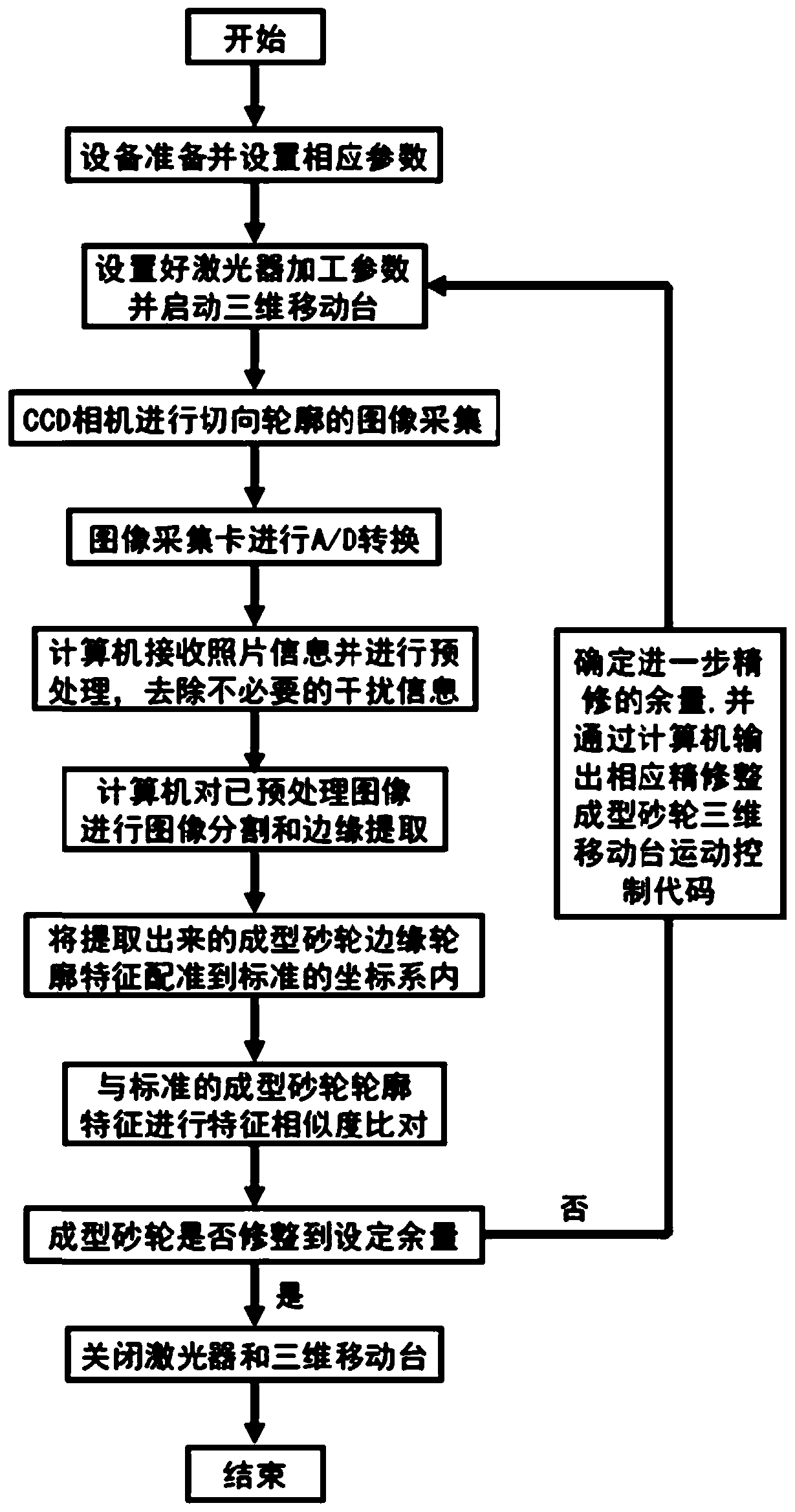

[0029] The following will be combined with Figure 1-3 The technical solution of the present invention is described in detail.

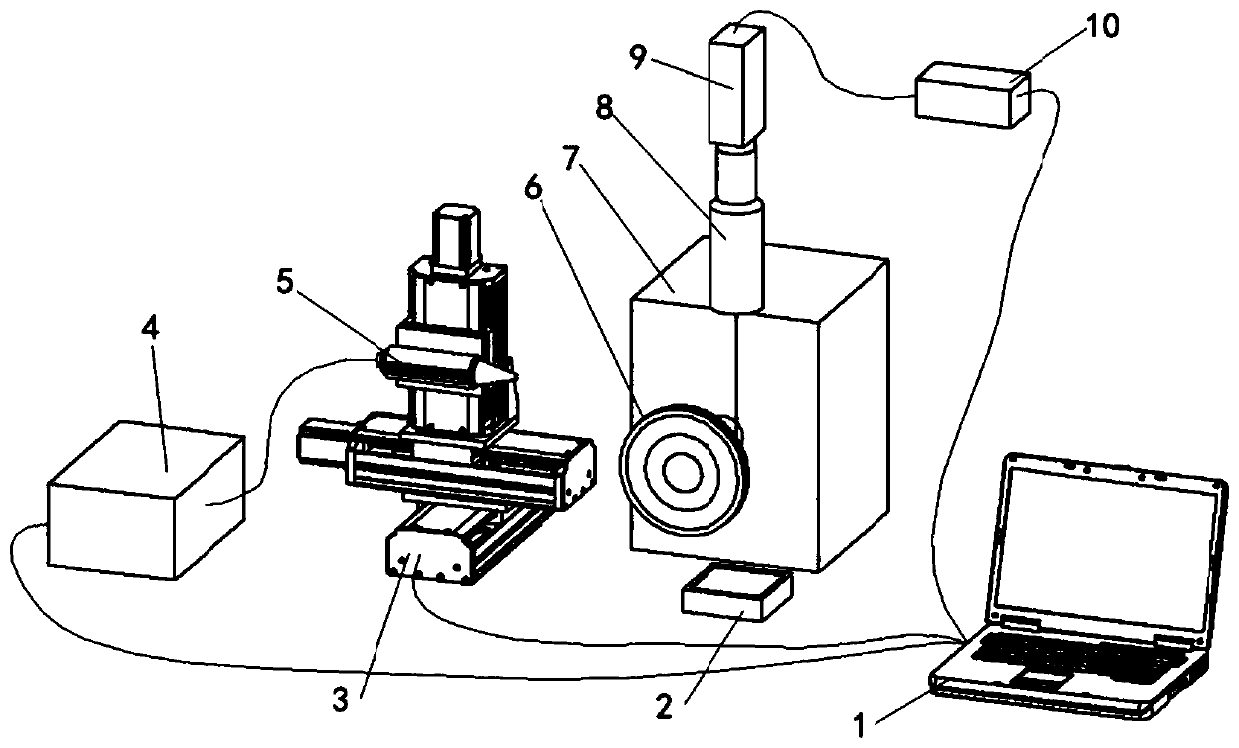

[0030] Such as figure 1 As shown, the present invention describes a laser trimming and forming grinding wheel device based on projection method contour detection, which specifically includes a computer 1, a backlight 2, a three-dimensional mobile platform 3, a fiber laser 4, a laser ablation head 5, a forming grinding wheel 6, and a grinding machine 7. Telecentric lens 8, CCD camera 9, image acquisition card 10;

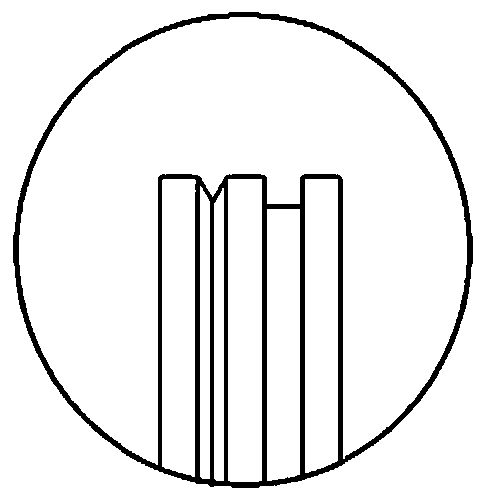

[0031]The laser ablation head 5 on the fiber laser 4, the forming grinding wheel 6 is installed on the controllable grinding machine 7, the forming grinding wheel 6 is driven to rotate by the grinding machine 7, the telecentric lens 8 is vertically placed on the upper right of the forming grinding wheel 6 and its optical axis is in line with the forming The periphery of the grinding wheel is tangent, while ensuring that the point of tange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com