Abrasive belt grinding machine

An abrasive belt grinder and abrasive belt technology, applied in the field of workpiece grinding, can solve the problems of wasted grinding time, decreased grinding quality, and reduced production speed, and achieve the effects of saving abrasive belts, improving uniformity, and uniform grinding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

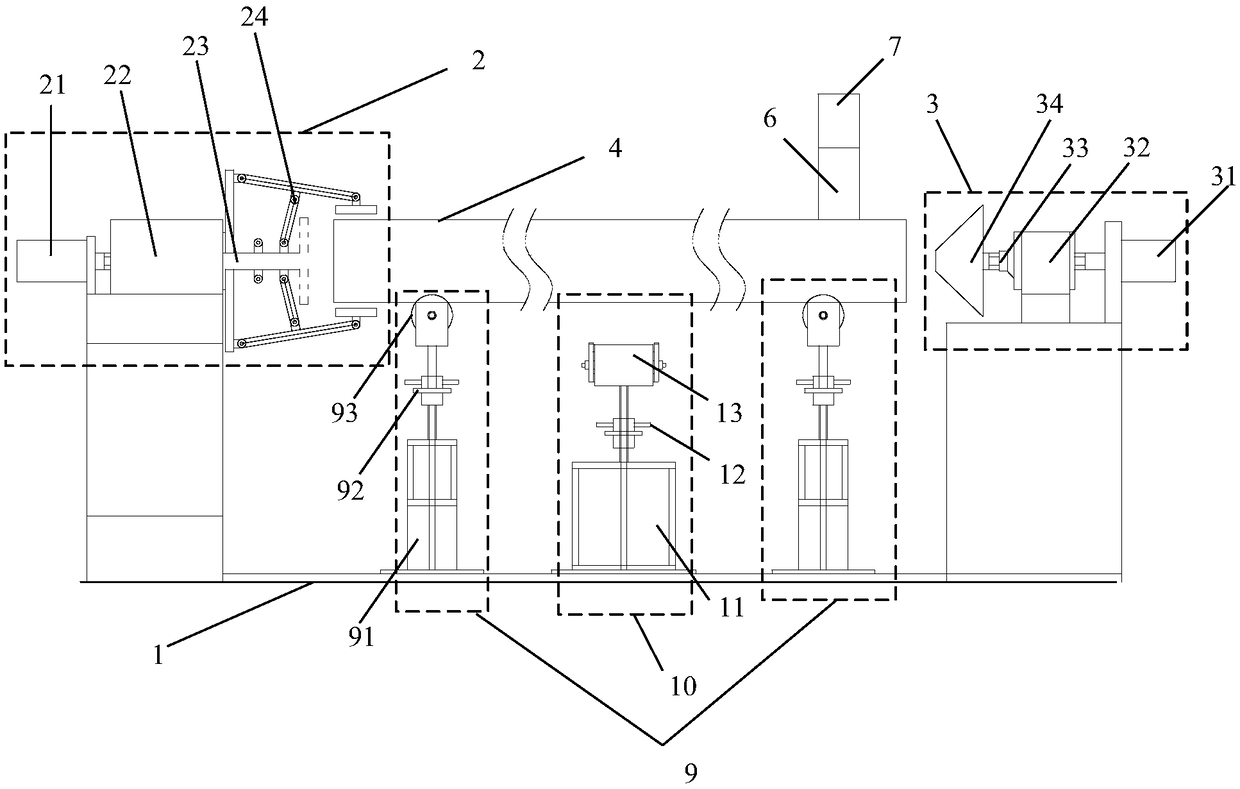

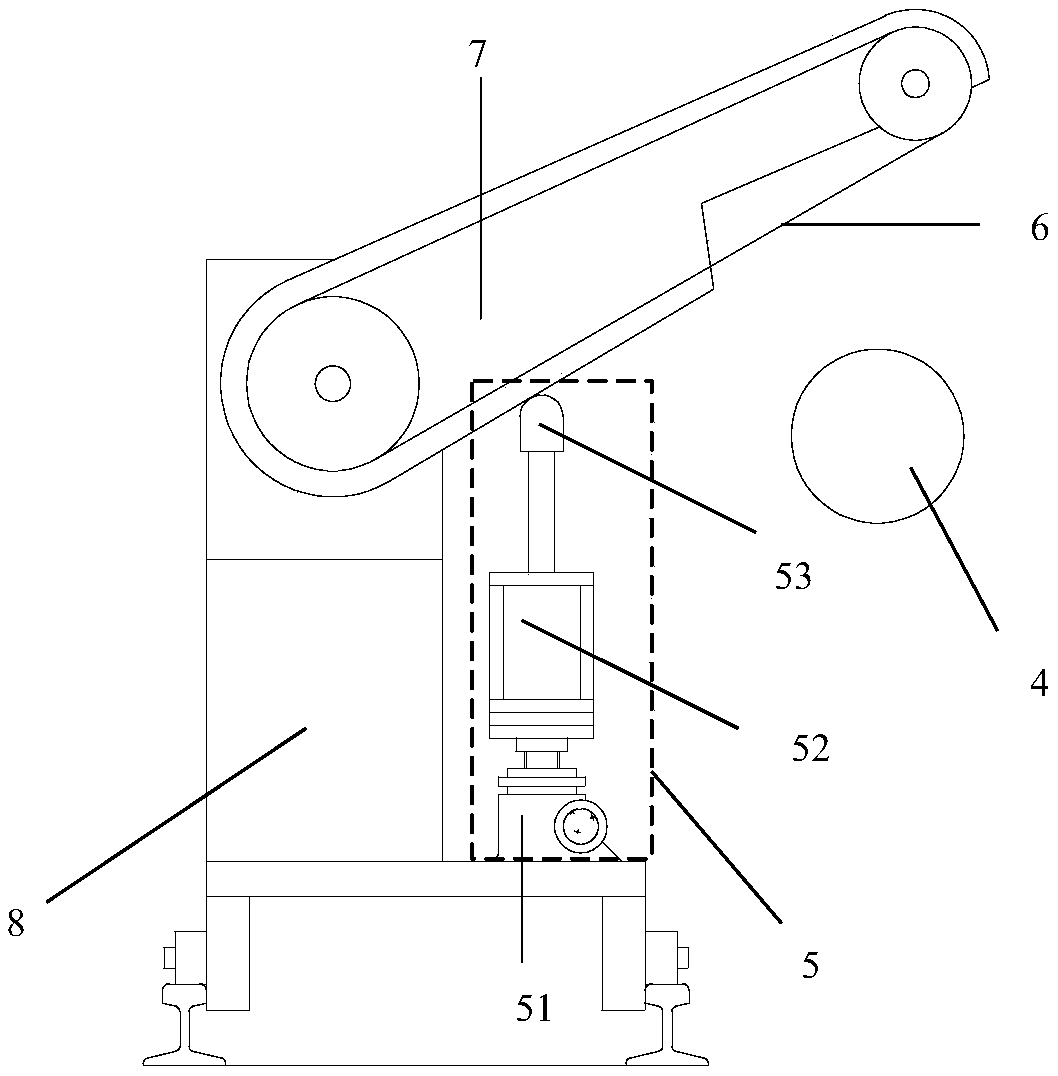

[0025] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, the embodiment of the present invention provides a kind of abrasive belt grinder, and this abrasive belt grinder comprises:

[0026] The bed body 1 and the first clamping part 2 and the second clamping part 3 fixed on the bed body 1 and arranged oppositely, the first clamping part 2 and the second clamping part 3 are respectively used for the two ends of the workpiece 4 to be polished For fixing, the first clamping part 2 is connected to the rotary drive part (not shown in the figure), and the rotary drive part is used to drive the first clamping part 2 to drive the workpiece 4 to be polished to rotate;

[0027] The grinding part and the grinding head support mechanism 5, the grinding part comprises an abrasive belt 6 and a grinding head 7, and the abrasive belt 6 is woun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com