Production system for automatic assembling of automobile horn assembly

A production system and horn technology, which is applied in the field of production system for automatic assembly of automobile horn components, can solve the problems of chaotic production rhythm, low assembly production efficiency, large inventory of parts, etc., to improve the degree of automation, improve assembly efficiency and assembly. Reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

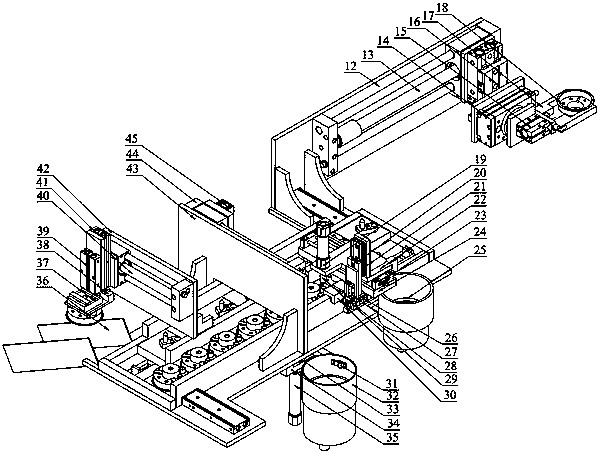

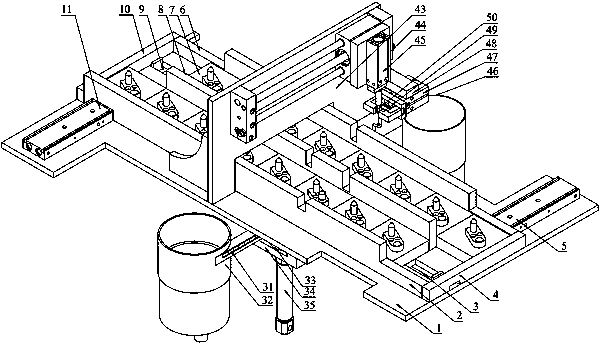

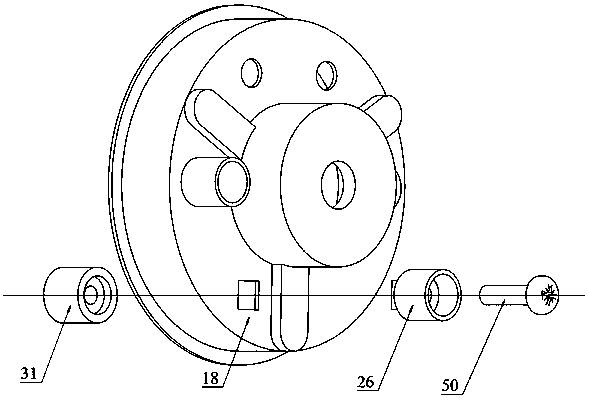

[0035] The initial state of the housing transported into the cylinder 13 is that the slider of the housing transported into the cylinder 13 is located at the shell removal position, and the state of the workpiece is that the slider is located at the shell release position; the initial state of the rotary cylinder 14 is to make the housing grabbing cylinder 15 pneumatically The shell clamp 17 on the finger is facing towards the shell position, and another state of the rotary cylinder 14 is to make the shell clamp 17 on the pneumatic finger of the grab cylinder shell grab cylinder 15 move towards the shell release position; the shell grab cylinder The initial state of 15 is the unclamped state, the working state of the housing grasping cylinder 15 is the grasping state; the initial state of the insulator traversing cylinder 23 is that its sliding table is at the insulating piece position, and the other state is that its sliding table is at the releasing position. Insulator positi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com