Technical equipment for modifying polymer materials

A technology of polymer materials and technical equipment, applied in the field of modified polymer material technical equipment, can solve the problems of uneven grinding and pressing of raw materials, cumbersome use steps, low grinding and pressing efficiency, etc., and achieves convenient operation, increased use safety, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

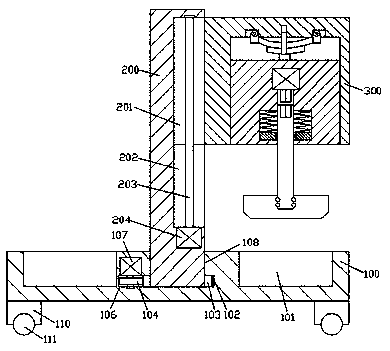

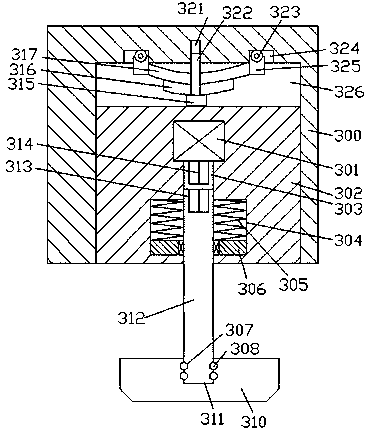

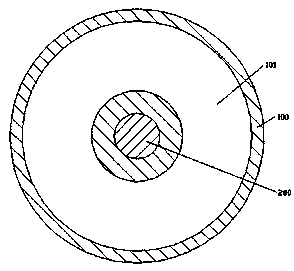

[0013] Combine below Figure 1-3 The present invention will be described in detail.

[0014] refer to Figure 1-3 , a modified polymer material technical equipment according to an embodiment of the present invention, comprising a steering column 200 disposed in the top end surface of the base 100 and a main base body 300 disposed on one side of the steering column 200 through lifting and lowering components, A foot bar 110 is fixed around the bottom end surface of the base 100, and a universal wheel 111 is mounted on the bottom end surface of the foot bar 110. A first steering cavity 108 is arranged in the center of the top end surface of the base 100. The extended section at the bottom of the steering column 200 is connected to the first steering cavity 108 in turn, and the inner wall of the first turn cavity 108 is provided with an annular cavity 102, and the ring cavity 102 is provided with a rotation fit with the said first turning cavity 108. The outer surface of the st...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap