Novel mailbox device

A mailbox, a new type of technology, applied in the direction of grinding drive devices, grinding machine parts, machine tools suitable for grinding workpiece planes, etc., can solve the problem of damage to the health of operators, cumbersome grinding operation steps, uneven outer surface, etc. problems, to achieve the effect of improving grinding efficiency, realizing automatic control of locking and unlocking work, and improving grinding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

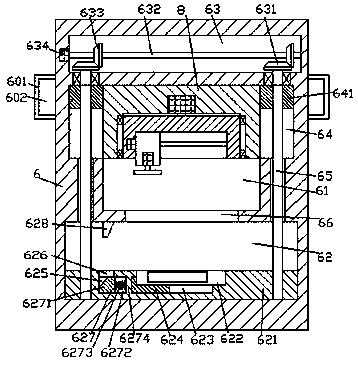

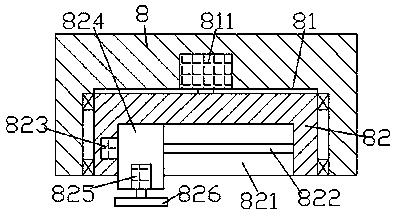

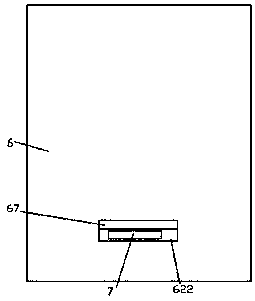

[0016] Combine below Figure 1-4 The present invention will be described in detail.

[0017] refer to Figure 1-4 , a new letterbox device according to an embodiment of the present invention, comprising a main base body 6, a first sliding joint cavity 61 is provided inside the main base body 6, and the inner walls of the left and right sides of the first sliding joint cavity 61 are symmetrical A guide groove 64 is provided, and a second sliding connection cavity 62 is provided in the main base body 6 on the lower side of the first sliding connection cavity 61 , and the gap between the first sliding connection cavity 61 and the second sliding connection cavity 62 A through opening 66 is provided in part, and a transmission chamber 63 is provided in the main seat body 6 on the upper side of the first sliding connection chamber 61, and the connection groove 64 on the left and right sides and the transmission chamber 63 Part of the internal rotation is connected with the first b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com