Low-temperature-increase rice processing technical method

A technology of rice processing and process method, applied in application, grain processing, grain milling, etc., can solve the problems of rice grain collision and tumbling, rice grain resistance to compression, bending and shear strength reduction, cooling rice grains to reduce rice temperature, etc. Achieve the effect of reducing broken rice rate, reducing temperature difference, and reducing coarse broken rice

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 2 example

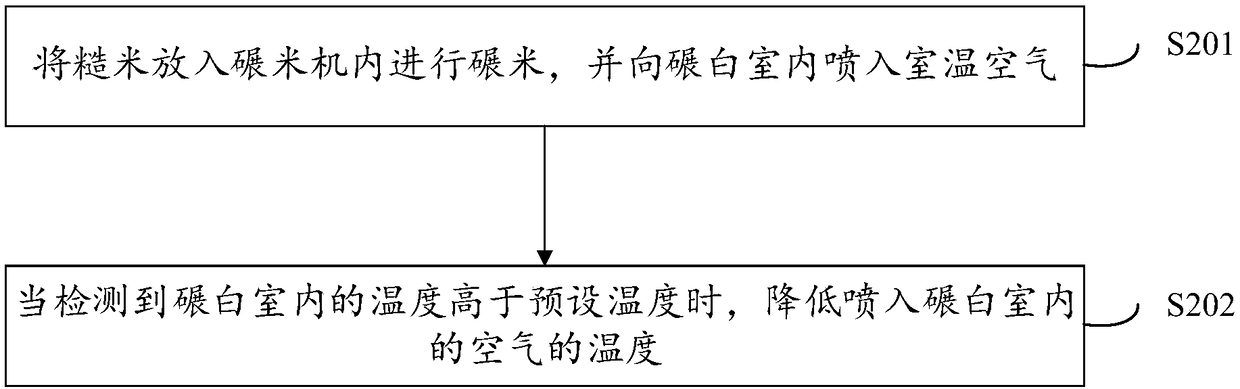

[0047] refer to figure 2 , is the second embodiment of the low-temperature rising rice processing method of the present invention, and the rice milling step includes:

[0048] Step S201, putting the brown rice into the rice mill for milling, and spraying air at room temperature into the milling room.

[0049] Specifically, the KFM2525B type low-temperature rising air jet sand roller rice unit (multi-machine light milling) is adopted. This type of rice milling machine has a strong jet (the air volume penetrating the whitening room is 2.1 times that of a conventional rice machine), multi-point air intake (The whitening room has a good bran discharge effect, and the body chamber has a smooth discharge of bran), which can slow down the temperature rise of the surface of the rice grain during the rice milling process to the greatest extent, and reduce the temperature difference between the surface and the inner layer of the rice grain. Therefore, the temperature rise is low, and th...

no. 3 example

[0056] refer to image 3 , is the third embodiment of the low-temperature rising rice processing method of the present invention, and the rice milling step includes:

[0057] Step S211, when the flow rate of the brown rice passing through the rice mill is greater than or equal to the first preset flow rate, spray air at the first temperature into the whitening chamber;

[0058] Step S212, when the flow rate of the brown rice passing through the rice mill is greater than or equal to the second preset flow value and less than the first preset flow value, spray air at a second temperature into the whitening chamber, and the second temperature less than the first temperature;

[0059] Wherein, the first preset flow rate is the flow rate of the rice mill when the broken rice rate of the rice milling step is 3%, and the second preset flow rate is the flow rate of the rice mill when the broken rice rate of the rice milling step is 1%. flow.

[0060] When the flow rate of brown ric...

no. 4 example

[0061] refer to Figure 4 , is the fourth embodiment of the low-temperature rising rice processing method of the present invention, and the polishing step includes:

[0062] Step S301, watering the semi-finished rice from which the rice husk and bran sheets have been removed is sprayed with high-pressure air;

[0063] In step S302, the semi-finished rice after watering enters the polishing machine for polishing.

[0064] After the brown rice is whitened, the bran sheets are removed, and after spraying water and moistening the rice (the binding force between the endosperm and the rice bran is reduced, and because the added water is very little, only a thin film is formed on the surface of the rice grains. , and the polishing time is not long, and it has no effect on the moisture content of the rice), enter the polishing chamber of the polishing machine, and under a certain pressure and temperature, the surface of the rice grains is polished by friction. Polishing treatment ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com