Dust removal and desulphurization tower

The technology of desulfurization tower and dust removal tower is applied in the field of waste gas purification, which can solve the problems of difficult desulfurization, short contact time between absorbent and sulfur-containing gas, complicated structure of dust removal and desulfurization tower, etc., so as to prolong residence time, improve filtration effect and remove dust good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following is further described in detail through specific implementation methods:

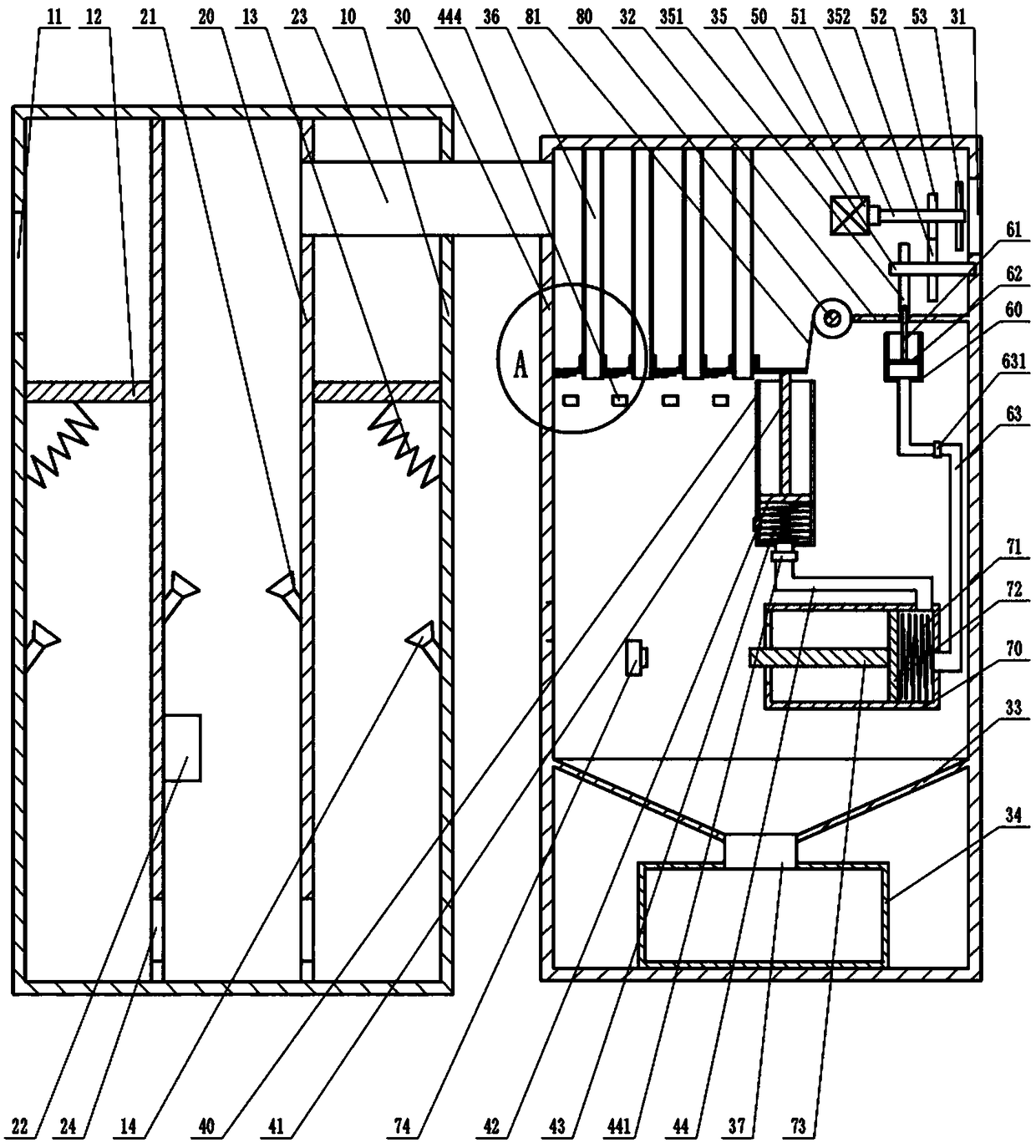

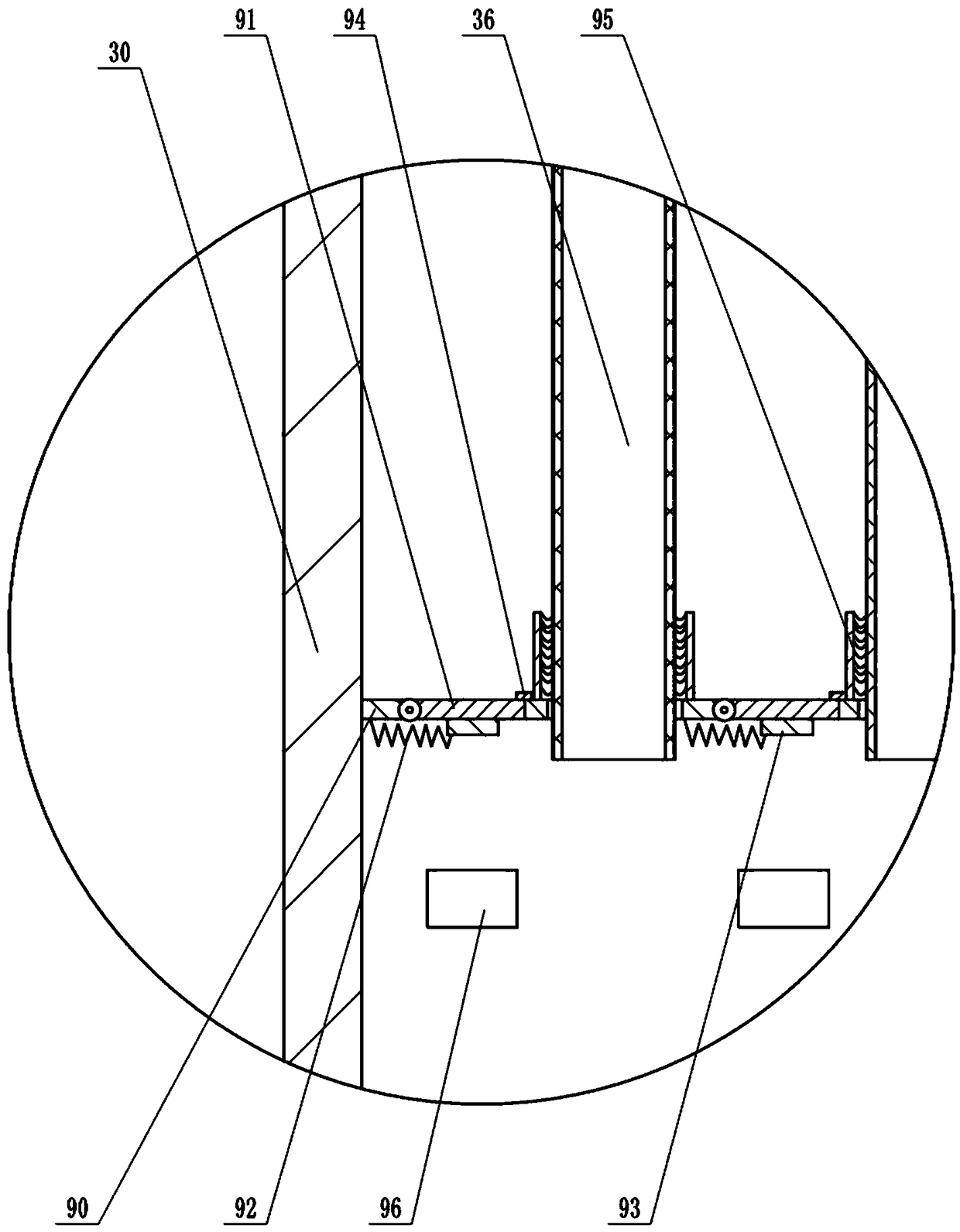

[0024] Instructions attached Figures 1 to 2 The reference signs in include: outer tower 10, air outlet 11, annular slide plate 12, spring 13, second nozzle 14, inner tower 20, first nozzle 21, exhaust fan 22, connecting pipe 23, outlet 24, dust removal tower 30 , air inlet 31, partition 32, conical funnel 33, dust box 34, rotating shaft 35, cam 351, second gear 352, dust removal mechanism 36, dust outlet pipe 37, second piston barrel 40, second push Rod 41, second piston 42, first tension spring 43, air pipe 44, solenoid valve 441, motor 50, rotating vane 51, first gear 52, first piston barrel 60, first push rod 61, first piston 62, Intake pipe 63, second one-way exhaust valve 631, third piston barrel 70, second extension spring 71, third piston 72, pressure rod 73, single control switch 74, row and turn roller 80, dustproof film 81, push Plate 90, material door 91, limit spring 9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com