Composition with anti-aging and wrinkle relaxing effects and preparation method and application thereof

A composition and plain weave technology, which is applied in the field of skin care, can solve the problems of not smooth facial lines, etc., and achieve the effects of avoiding premature aging of cells, enhancing activity, and improving skin condition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

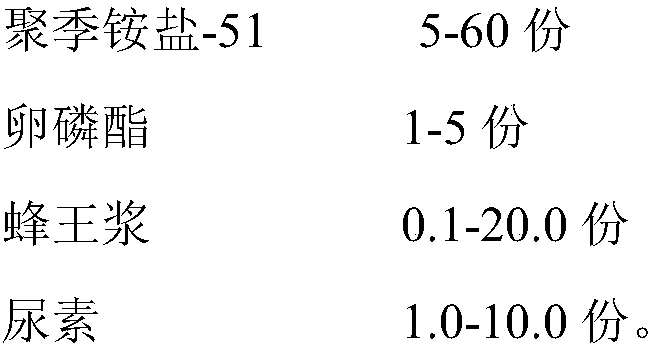

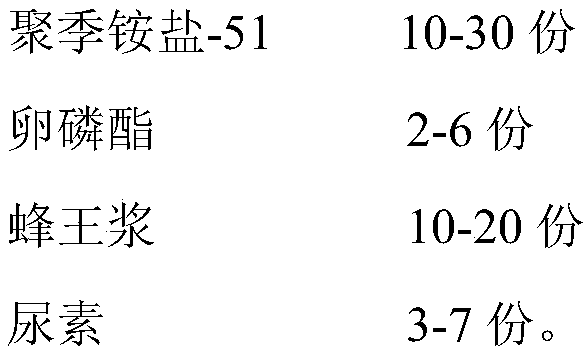

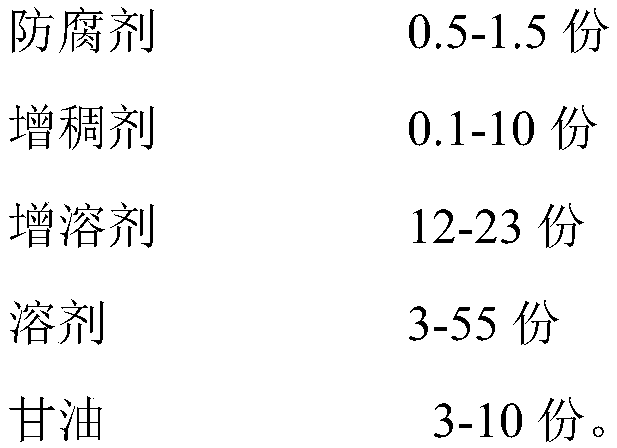

Method used

Image

Examples

Embodiment 1

[0045] A composition with anti-aging plain weave effect, prepared by the following method:

[0046] 1. Weigh each raw material according to the following mass percentages and set aside.

[0047] Polyquaternium-51 is 20.0%, lecithin is 4.0%, royal jelly is 15.0%, urea is 5.0%, phenoxyethanol is 1.0%, xanthan gum is 1.0%, glycerin is 3.0%, Tween-20 is 16.0%, and the balance is water (35%).

[0048] 2. Preparation method.

[0049] (1) Stir and mix lecithin and Tween-20 evenly for later use

[0050] (2) Mix glycerin and xanthan gum evenly, add water, stir to dissolve completely, add the premixed lecithin and Tween-20 mixed solution, then add polyquaternium-51, royal jelly, urea and phenoxyethanol , to obtain a liquid composition A with a consistency, and keep it for later use.

Embodiment 2

[0052]A composition B with anti-aging plain weave effect is basically the same as the composition of Example 1, except that the content of each raw material is 10.0% for polyquaternium-51, 1.0% for lecithin, and 1.0% for royal jelly 3.0% of urea, 1.0% of urea, 1.0% of phenoxyethanol, 1.0% of xanthan gum, 3.0% of glycerin, 10.0% of Tween-20, and the balance of water (70%).

Embodiment 3

[0054] The skin care product I with anti-aging flat lines is prepared by the following method:

[0055] 1. Weigh each raw material according to the following mass percentages and set aside.

[0056] Table 1. Raw material composition of each skin care product

[0057] 2. Preparation method.

[0058]

[0059] (1) Add phase A into the oil phase pot and heat to 80-85°C while stirring;

[0060] (2) Add the water in phase B to the water phase pot, add raw materials 9-11 under stirring state, and slowly add raw material 12 under stirring state, heat to 80-85°C and stir until completely dissolved and evenly, then pump into the emulsification pot Inside;

[0061] (3) Pump the heated phase A into the emulsification pot, emulsify and homogenize for 5 minutes, and keep warm at 80-85°C for 30 minutes.

[0062] (4) Cool down, cool to 50°C under stirring, add phase C, homogenize;

[0063] (5) While stirring, continue to cool down to 45°C, and add phase D;

[0064] (6) Stir evenly, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com