Water-soluble nut oil microcapsules rich in Omega-7 and preparation method of water-soluble nut oil microcapsules rich in Omega-7

A technology for nut oil and microcapsules, applied in the field of water-soluble nut oil microcapsules and their preparation, can solve problems such as low yield, achieve the effects of easy storage, simple and easy process, and low processing degree and utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

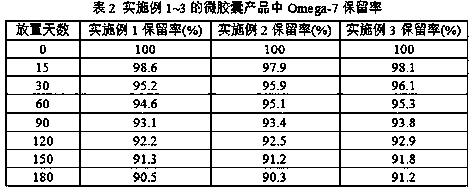

Embodiment 1

[0027] Embodiment 1 adopts the following steps to realize the present invention:

[0028] (1) Preparation of mixed fatty acids of macadamia nut oil: Weigh 2kg of macadamia nut oil, add 220.0g KOH and 4L 95% edible alcohol, reflux and stir in a water bath at 75~80℃ for 2~3h to obtain a solution; after the reaction, add 0.2 times the volume of distilled water to promote solution clarification, rotary distillation to remove alcohol, add hydrochloric acid to acidify to pH 2~3, transfer to a separatory funnel to stand for stratification; take the upper organic phase, wash with 5% NaCl water until the pH of the solution is Neutral, to get macadamia oil mixed fatty acids;

[0029] (2) Core material preparation: Weigh 200ml of macadamia nut mixed fatty acids prepared in step (1), 2 Extraction in the fluid fractionation column device, extraction conditions: extraction kettle pressure 200 bar, CO 2 The flow rate is 5L / min, the material feed flow rate is 1mL / min, the temperature field ...

Embodiment 2

[0032] Embodiment 2 adopts the following steps to realize the present invention:

[0033] (1) Preparation of core material: Weigh 200ml of macadamia nut mixed fatty acid prepared in step (1) of Example 1, and store in supercritical CO 2 Fractionation column device for extraction, extraction conditions: extraction kettle pressure 250 bar, CO 2 The flow rate is 7L / min, the material feed flow rate is 1.5mL / min, the temperature field is applied from the bottom to the top of the fractionation column at 40-90°C, and the extraction is for 1 hour to obtain the core material;

[0034] (2) Embedding and shearing emulsification: Maltodextrin and soybean protein isolate (2:1 by mass ratio) are used as compound wall materials, and monoglyceride and sucrose ester (1:1 by mass ratio) are used as compound emulsifiers ; Weigh the core material and compound wall material according to the mass ratio of core material to wall material 1:2, dissolve 20g of compound wall material in 100ml of 60~65°...

Embodiment 3

[0036] Embodiment 3 Adopt the following steps to realize the present invention:

[0037] (1) Preparation of core material: Weigh 200ml of macadamia nut mixed fatty acid prepared in step (1) of Example 1, and store in supercritical CO 2 Extraction conditions of fluid fractionation column device: extraction kettle pressure 200 bar, CO 2 The flow rate is 3L / min, the material feed flow rate is 1.5mL / min, the temperature field is applied from the bottom to the top of the fractionation column at 40-80°C, and the extraction is for 1 hour to obtain the core material;

[0038] (2) Embedding and shearing emulsification: Maltodextrin and soybean protein isolate (2:1 by mass ratio) are used as compound wall materials, and monoglyceride and sucrose ester (1:1 by mass ratio) are used as compound emulsifiers ; Take the core material and compound wall material according to the mass ratio of core material and wall material 1:2, dissolve 20g of compound wall material in 100ml of 60~65°C distil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com