Foam type disinfectant for farms as well as preparation method and application thereof

A disinfectant and foam-type technology, which is applied in the field of foam-type disinfectant for farms and its preparation, can solve the problems of uneven diffusion of disinfectants, incomplete disinfection, and large water consumption, so as to prolong the half-life of destruction and improve product quality Stability, water saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

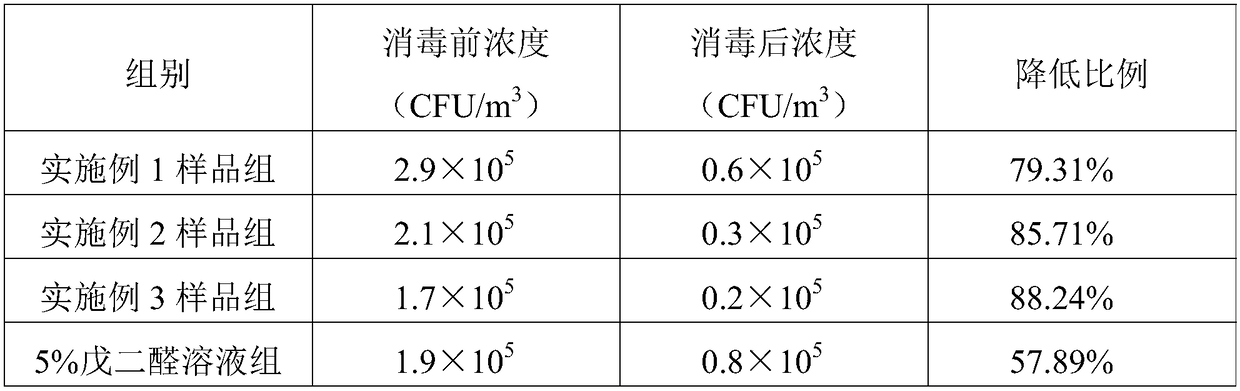

Examples

Embodiment 1

[0032] A high-foam disinfectant for farms, which is calculated in parts by weight, and every 100 parts of disinfectant consists of the following components: 5 parts of glutaraldehyde, 5 parts of compound chlorine dioxide, 5 parts of decyl methyl ammonium bromide, and fatty alcohol Polyoxyethylene ether (AEO-7) 0.5 parts, fatty alcohol polyoxyethylene ether sulfonate sodium 25 parts, Tween-80 1.5 parts, Na 2 HPO 4 0.1 part, NaH 2 PO 4 0.1 part, the balance is water. Weigh the raw materials in proportion, dissolve and mix them evenly, and seal and fill them.

Embodiment 2

[0034] A high-foaming disinfectant for farms, which is calculated in parts by weight, and each 100 parts of disinfectant consists of the following components: 5 parts of glutaraldehyde, 5 parts of compound chlorine dioxide, 5 parts of decyl methyl ammonium bromide, and saponins 15 parts of fatty alcohol polyoxyethylene ether (AEO-7) 10 parts, 15 parts of fatty alcohol polyoxyethylene ether sulfonate sodium, 8 parts of sodium dodecylbenzene sulfonate, 1.5 parts of n-dodecane, alginic acid 0.2 part of sodium, Na 2 HPO 4 0.1 part, NaH 2 PO 4 0.1 part, the balance is water. Weigh the raw materials in proportion, dissolve and mix them evenly, and seal and fill them.

Embodiment 3

[0036] A high-foam disinfectant for farms, which is calculated in parts by weight, and every 100 parts of disinfectant consists of the following components: 5 parts of glutaraldehyde, 10 parts of sodium hypochlorite, 15 parts of alkyl polyglycoside, and polyoxyethylene rosin 10 parts, 15 parts of fatty alcohol polyoxyethylene ether sodium sulfate, 2.5 parts of propylene glycol, Na 2 HPO 4 0.1 part, the balance is water. Weigh the raw materials in proportion, dissolve and mix them evenly, and seal and fill them.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com