An agricultural fungus plant culture material weeder

A weeding machine and compost technology, applied in agricultural machinery and tools, agriculture, application, etc., can solve the problems of unfavorable protection plate and knife holder disassembly and replacement, unfavorable maintenance and repair of weeder, and increased labor intensity of users, etc., to achieve It is safe and convenient to use, increase weight, and avoid the effect of substance residue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

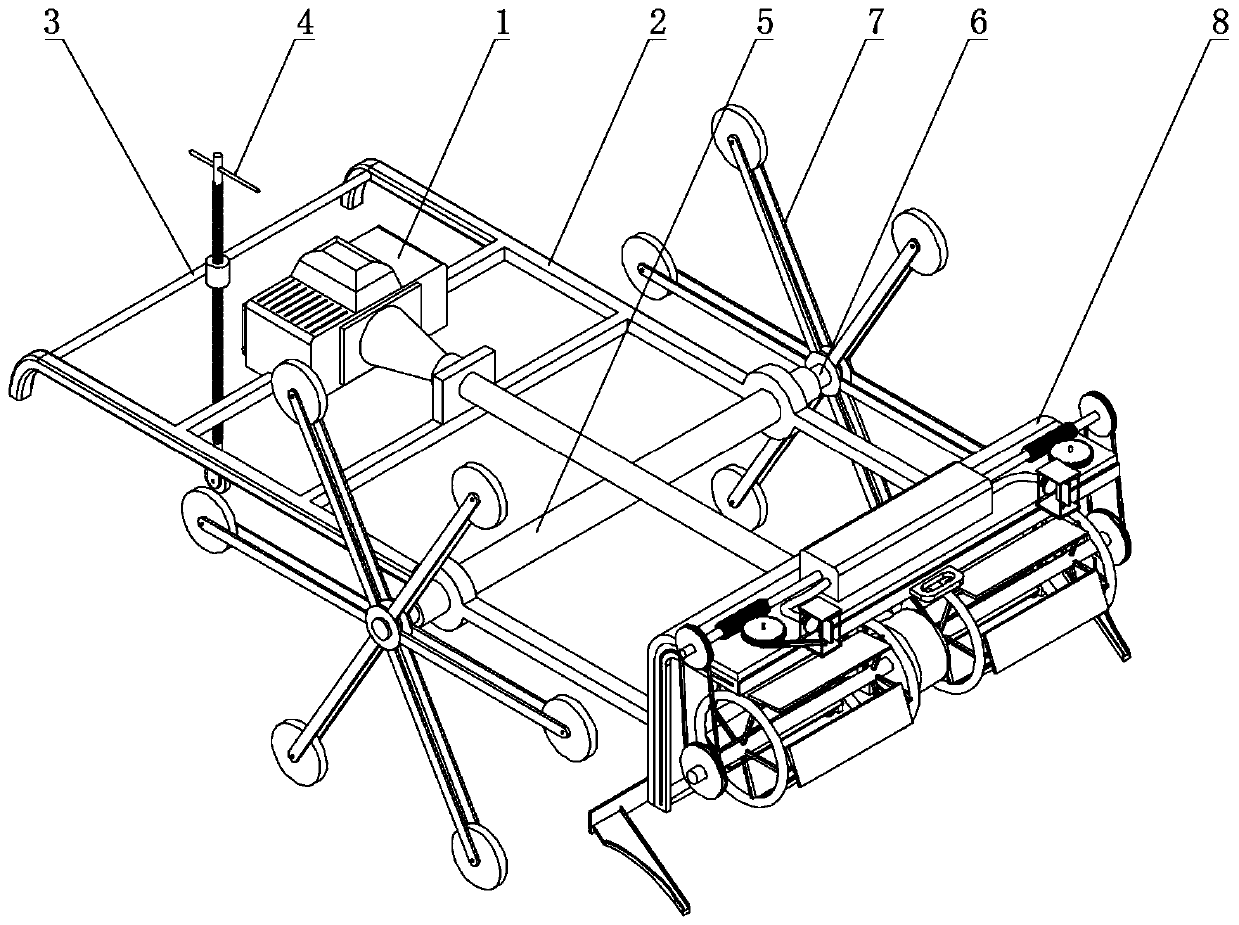

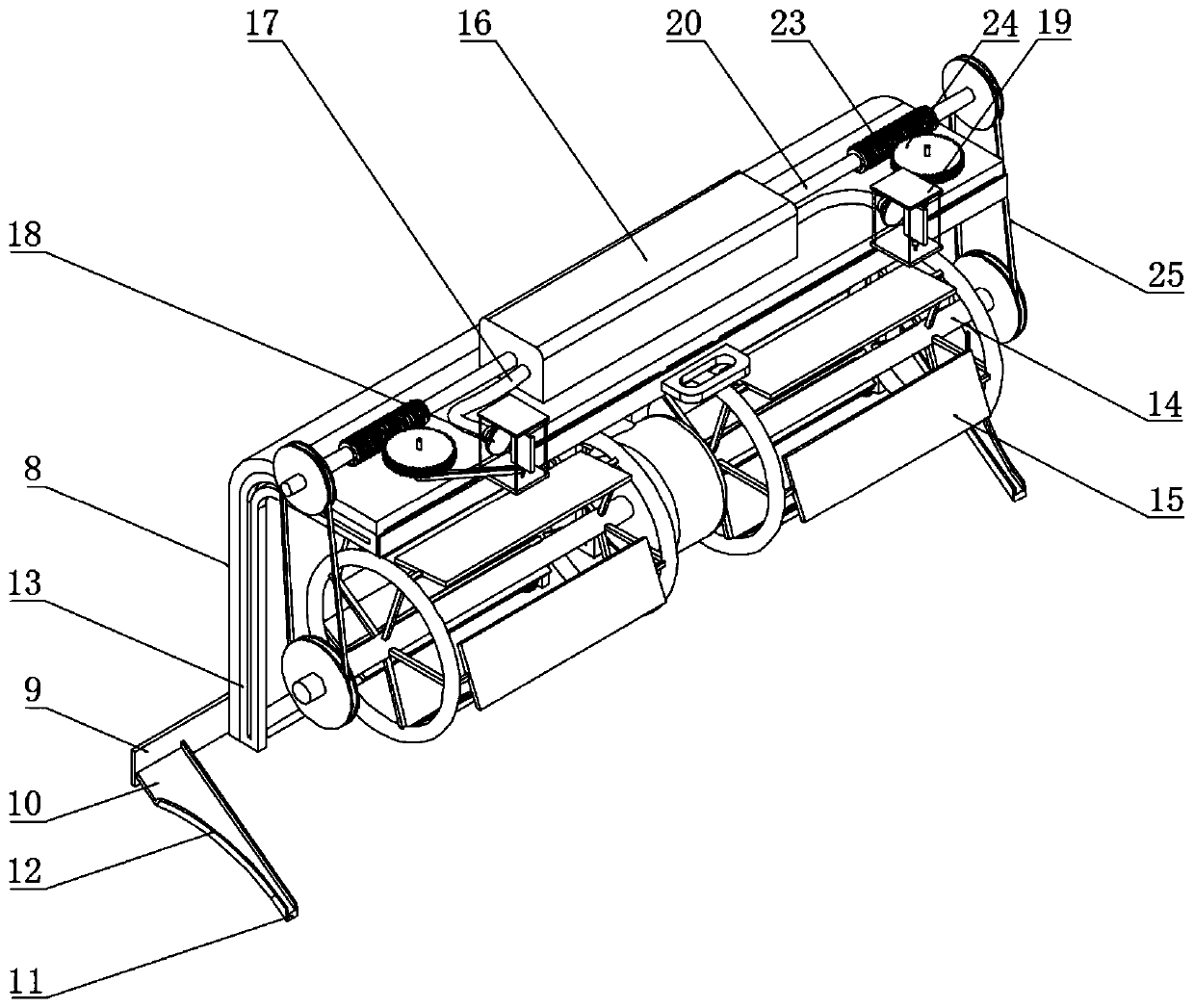

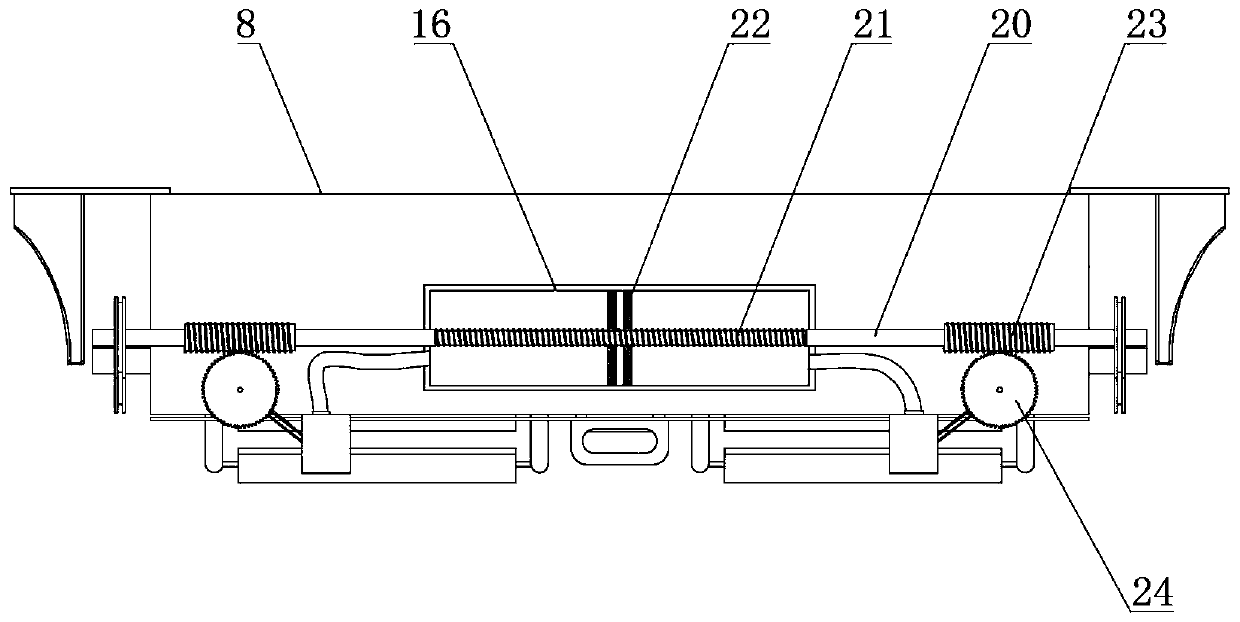

[0032] Example: such as Figure 1-8 As shown, the present invention provides a technical solution, an agricultural fungus plant culture material weeder, comprising a weeder body 1, a mounting frame 2 is installed under the weeder body 1, and a push rod 3 is installed on one side of the mounting frame 2, A steering mechanism 4 is installed in the middle of the push rod 3, and the steering mechanism 4 includes an internally threaded casing 401, a screw 402, an adjusting rod 403 and a steering wheel 404. A screw 402 is installed inside the internally threaded casing 401, and an adjusting rod 403 is installed on the top of the screw 402. , the steering wheel 404 is installed at the bottom of the screw rod 402, the installation sleeve 5 is installed in the middle of the installation frame 2, the support shaft 6 is installed inside the installation sleeve 5, and the moving mechanism 7 is installed symmetrically at both ends of the support shaft 6, and the moving mechanism 7 includes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com