Plug and socket for radio frequency connector, and self-locking anti-rotation radio frequency connector

A technology of radio frequency connectors and sockets, which is applied to the parts of connecting devices, devices for connecting/disconnecting connecting parts, connections, etc., which can solve the problems of cumbersome installation and disassembly procedures, failure of mechanical and electrical performance, and high requirements for installation accuracy , to achieve the effect of saving material and processing costs, improving fastening reliability, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

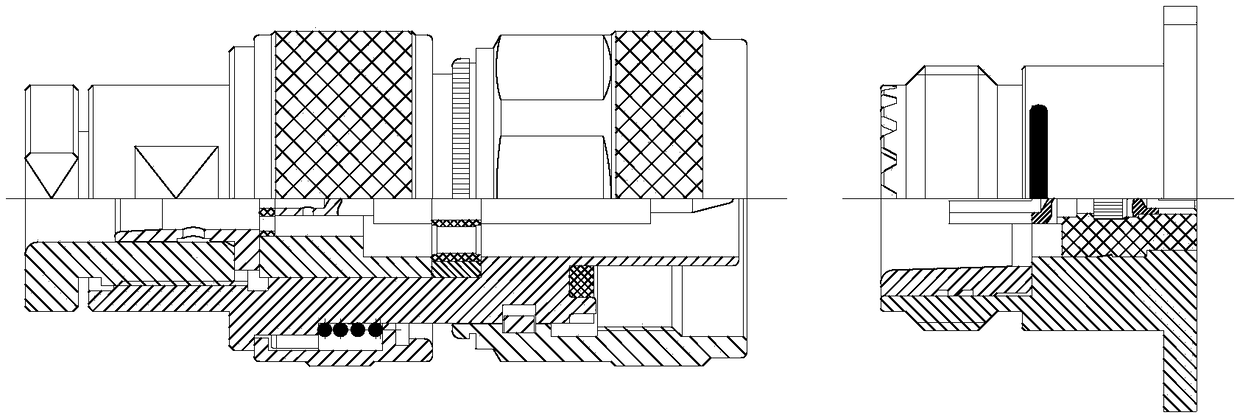

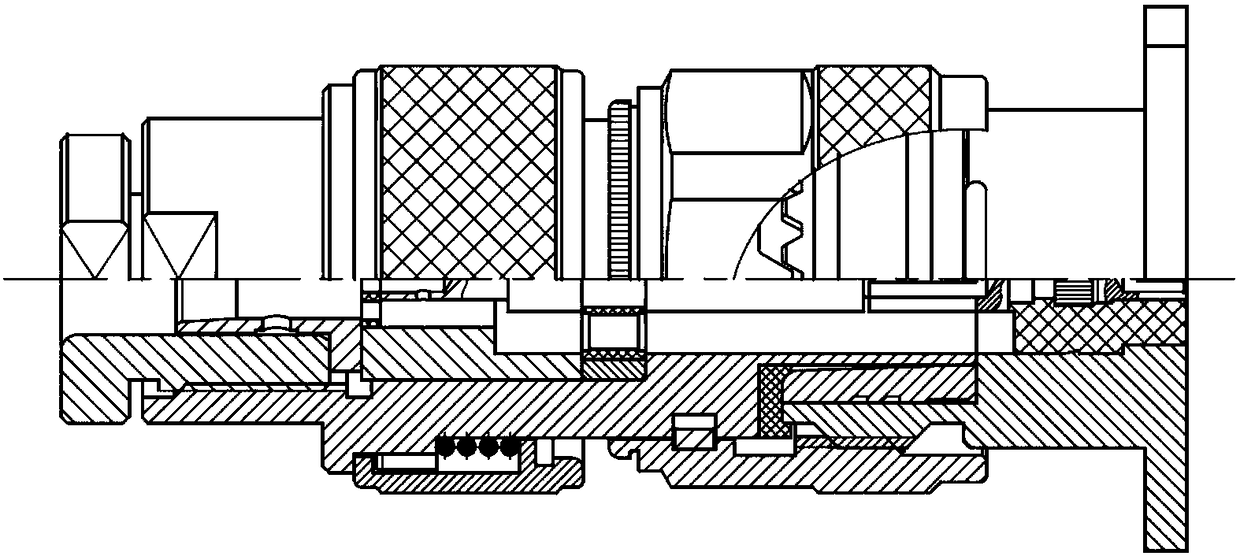

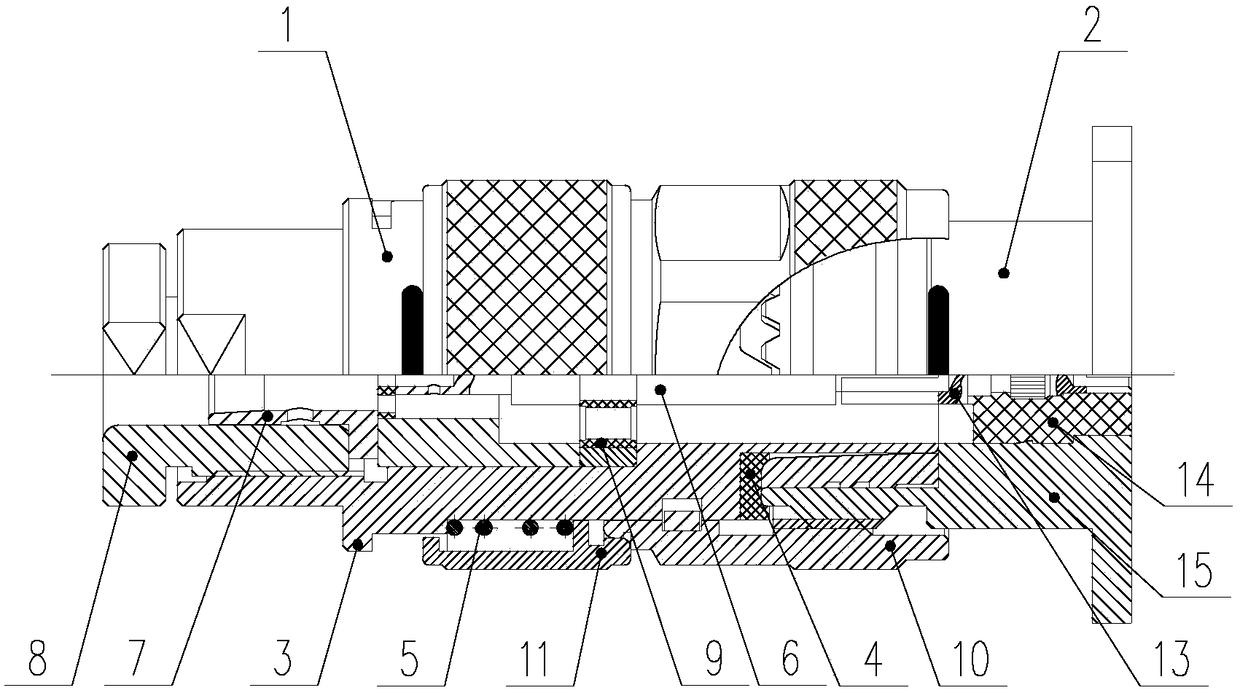

[0056] like image 3 , 4 , The self-locking anti-rotation radio frequency connector shown in 5 includes a plug 1 and a socket 2, and the plug 1 includes a plug housing 3, such as Figure 6 , 8 As shown in . The sleeve 10 is axially limited by the annular groove 25 and the snap ring 26, and the plug housing 3 is provided with an insulating medium 9, pins 6, bushings 7 and nuts 8; the insulating medium 9 plays the role of isolating and supporting the inner and outer conductors; The pin 6 plays the role of inner conductor connection and signal transmission, and the bushing 7 and nut 8 play the role of connecting and fixing the cable.

[0057] Socket 2 comprises socket housing 15, as Figure 5 and Figure 7 As shown, the bushing 12, the insulating medium 14 and the jack 13 arranged in the socket housing 15, wherein the insulating medium 14 plays the role of isolating and supporting the inner and outer conductors; the jack 14 plays the role of inner conductor connection and si...

Embodiment 2

[0075] This embodiment proposes a solution different from that of Embodiment 1 for the anti-rotation mechanism provided on the plug housing 3 and the socket housing 15, and the specific scheme is as follows:

[0076] like Figure 12 , 13 As shown, the first anti-rotation mechanism arranged axially on the end face of the socket housing 3 plugged with the socket housing 15 is a bar block 27, and on the end face of the socket housing 15 and the plug housing 3 butted in the axial direction. The second anti-rotation mechanism provided is an opening 28 mated with the bar-shaped block 27 , and the bar-shaped block 27 and the opening 28 are mated to realize the circumferential anti-rotation of the plug housing 3 and the socket housing 15 .

[0077] Compared with the anti-rotation gear 16 of the first housing and the anti-rotation gear 17 of the second housing in Embodiment 1, the anti-rotation mechanism given in this embodiment is simpler to process, and the machining accuracy does n...

Embodiment 3

[0079] like Figure 10 As shown, on the basis of Embodiment 1 or 2, a sealing ring 4 is provided on the plug housing 3 in this embodiment, and the sealing ring 4 is arranged at the mating place of the plug 1 and the socket 2, and the sealing ring 4 at the mating place Under the extrusion of the bushing 12 and the shell 3, it plays the role of sealing at the joint, and realizes the requirements of the sealing performance of the product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com