Anti-rotation device of thin-wall storage and transportation gas cylinder

An anti-rotation and gas cylinder technology, which is applied to the installation device of the container structure, the geometry/arrangement/dimension of the container structure, the outer wall of the container structure, etc. Thickness, thinning of gas cylinder thickness, etc., to prevent circumferential rotation and axial movement, reduce weight, and prevent rotation safely

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

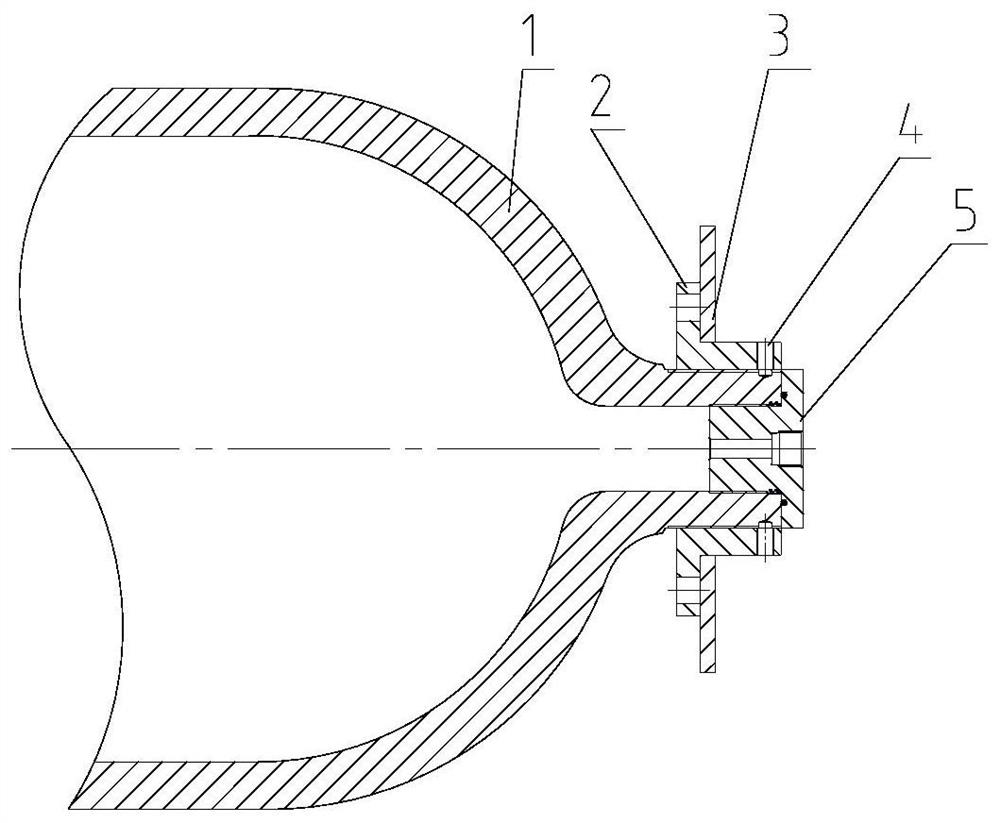

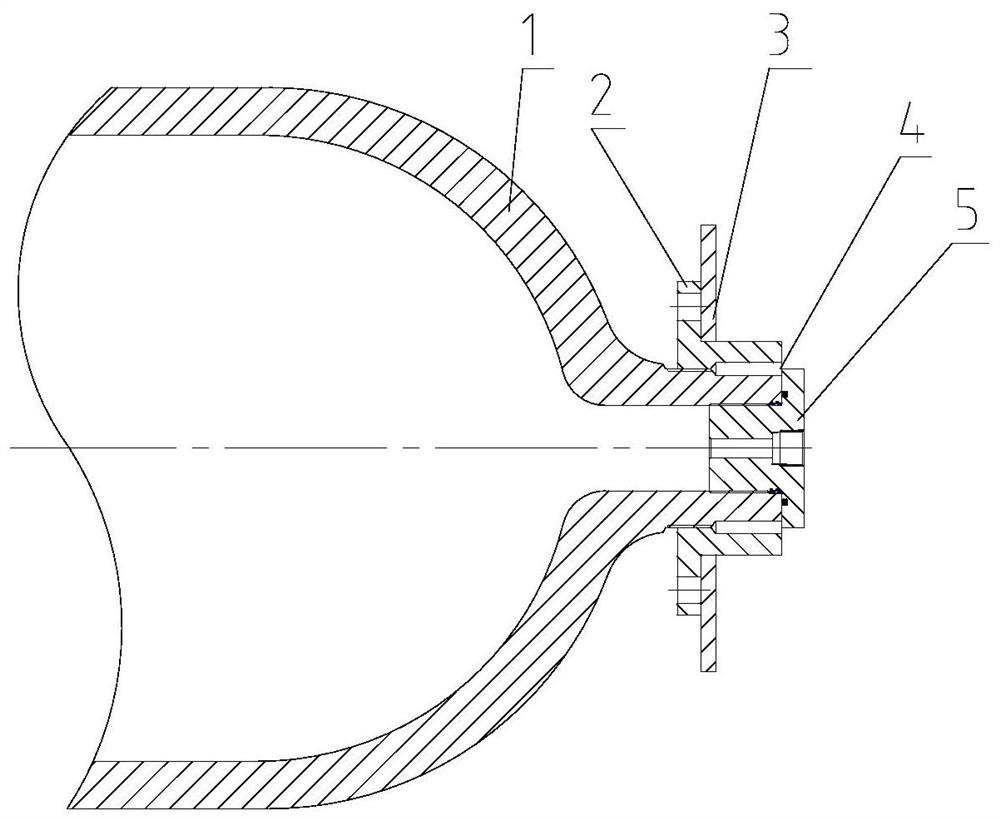

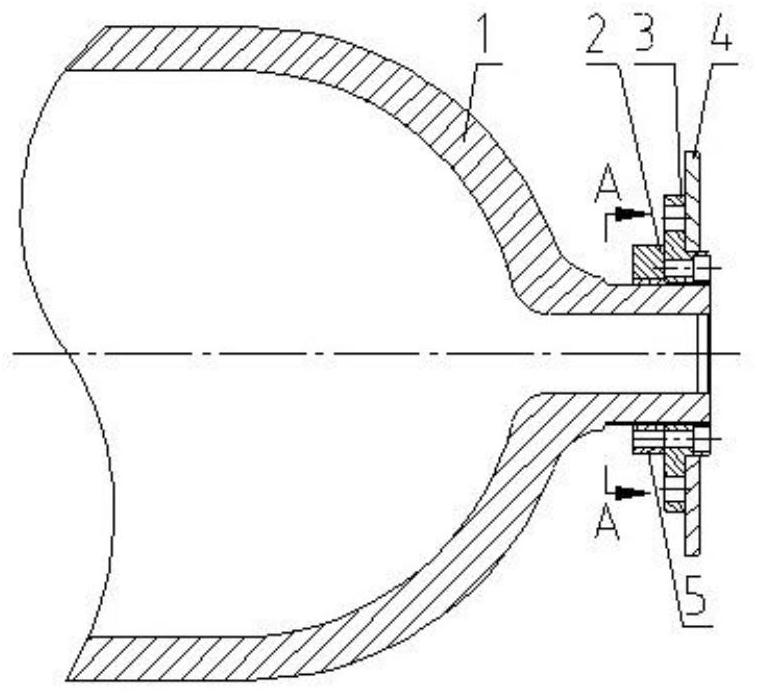

[0049] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. However, the present invention should be understood as not limited to such embodiments described below, and the technical idea of the present invention can be implemented in combination with other known technologies or other technologies having the same functions as those known technologies.

[0050]In the description of the following specific embodiments, in order to clearly demonstrate the structure and working mode of the present invention, many directional words will be used to describe, but "front", "rear", "left", "right", "outer ", "inward", "outward", "inward" and other words are understood as convenient terms, and should not be understood as limiting words. In addition, "axial" refers to the direction parallel to the bottleneck of the gas storage bottle; "radial" refers to the direction perpendicular to the bottleneck of the gas stora...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com