Rapid acquisition method of workpiece dynamics parameters in milling process

A technology of kinetic parameters and acquisition methods, applied in program control, instrument, computer control, etc., can solve the problems of complicated process, large amount of calculation, poor generality, etc., and achieve the effect of improving computing efficiency and saving computing time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

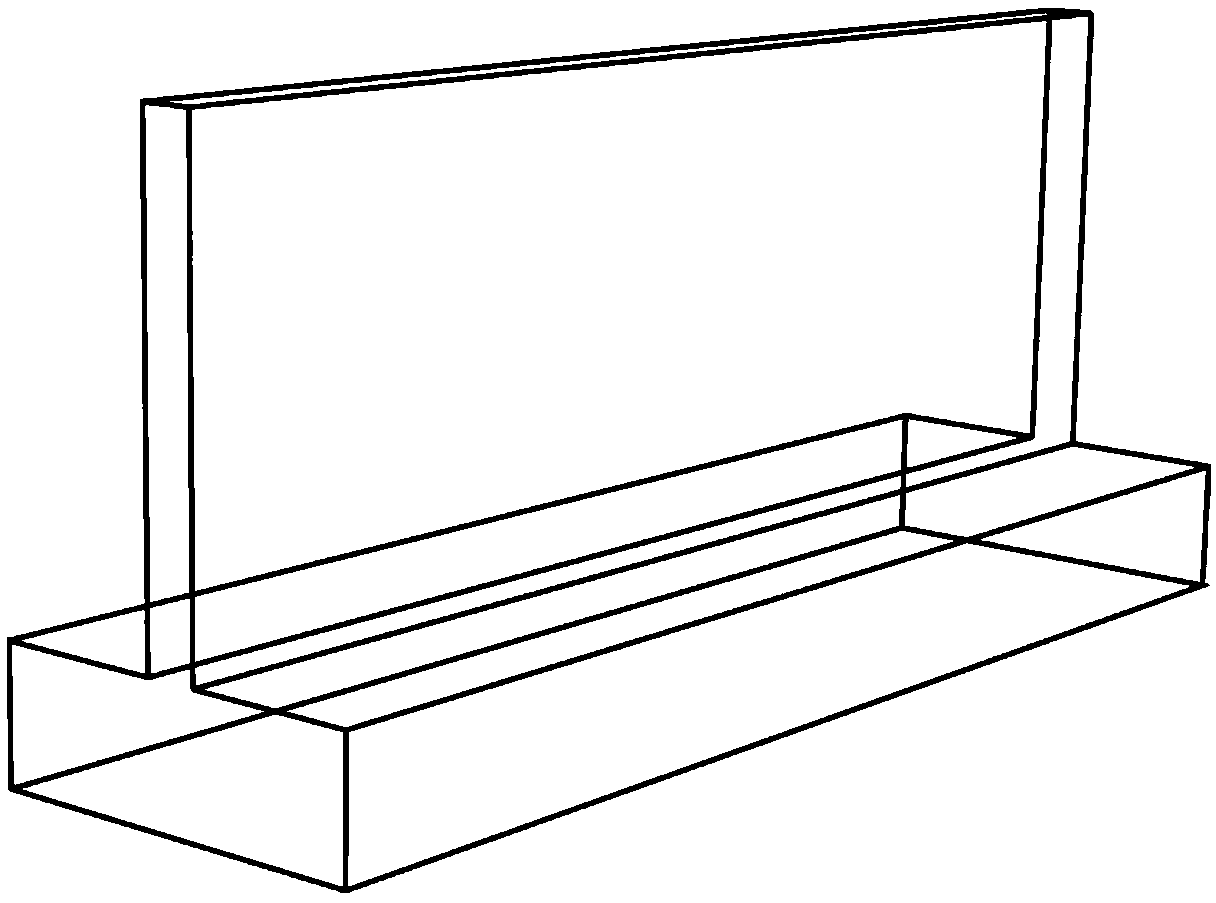

[0038] Example 1: The size of the thin plate is 102mm×36mm×4mm, the material is aluminum alloy 7075, the modulus of elasticity is 71GPa, and the density is 2810kg / m 3 , Poisson's ratio is 0.33.

[0039] 1. Aiming at the milling characteristics of thin-walled parts, establish a multi-point contact milling dynamics model that simultaneously considers the deformation of the tool and the workpiece; divide the contact area between the tool and the workpiece into 35 microelements along the axial direction, and divide the milling force of each unit Focus on nodes and find dynamic milling forces:

[0040]

[0041] The dynamic equation of the milling system is:

[0042]

[0043] m W,0,0 ,C W,0,0 , K W,0,0 Represents the mass, damping, and stiffness matrix of the initial workpiece; Q(t) represents the dynamic displacement of the workpiece in physical coordinates; transform the above formula from physical space to modal space to get:

[0044]

[0045] Γ w,0,0 (t) is the mo...

Embodiment 2

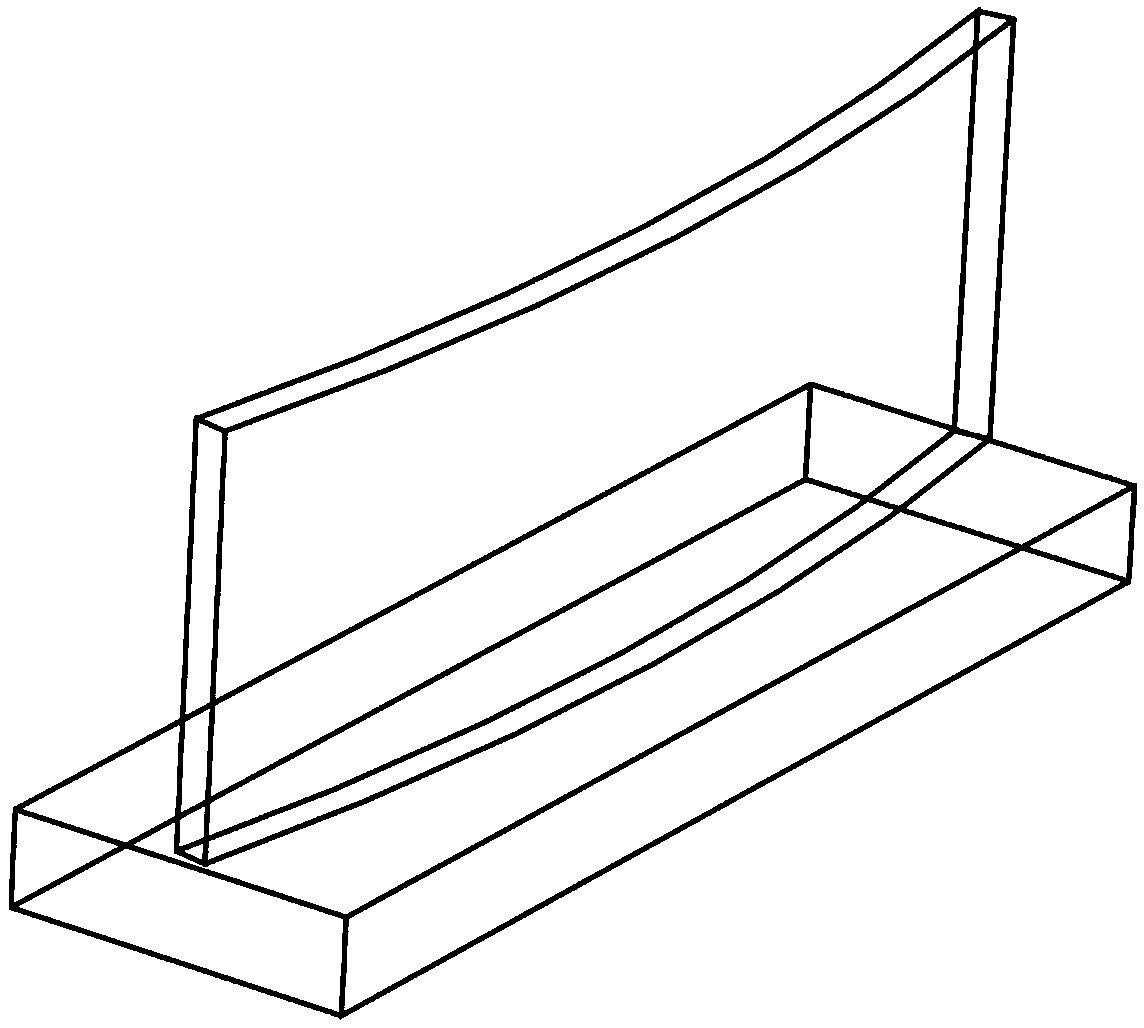

[0063] Example 2: The size of the curved thin plate is 104mm long, 35mm high, 3.5mm thick, and the radius of curvature is 297mm; the material is aluminum alloy 7075, the modulus of elasticity is 71GPa, and the density is 2810kg / m 3 , Poisson's ratio is 0.33.

[0064] 1. Aiming at the milling characteristics of thin-walled parts, establish a multi-point contact milling dynamics model that simultaneously considers the deformation of the tool and the workpiece; divide the contact area between the tool and the workpiece into 34 microelements along the axial direction, and divide the milling force of each unit Focus on nodes and find dynamic milling forces:

[0065]

[0066] The dynamic equation of the milling system is:

[0067]

[0068] m W,0,0 ,C W,0,0 , K W,0,0 Represents the mass, damping, and stiffness matrix of the initial workpiece; Q(t) represents the dynamic displacement of the workpiece in physical coordinates; transform the above formula from physical space to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Elastic modulus | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com