Low nitrogen emission coke-oven heating system adopting rich gas heating and adjustment method thereof

A heating system and gas-enriched technology, applied in combustible gas heating coke ovens, coke ovens, coke oven heating, etc., can solve the problems of increased system resistance, increased construction costs and production costs, and severe combustion, etc., to reduce nitrogen oxides The formation of pollutants, the reduction of the formation of nitrogen oxides, and the effect of reducing the emission of nitrogen oxides

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

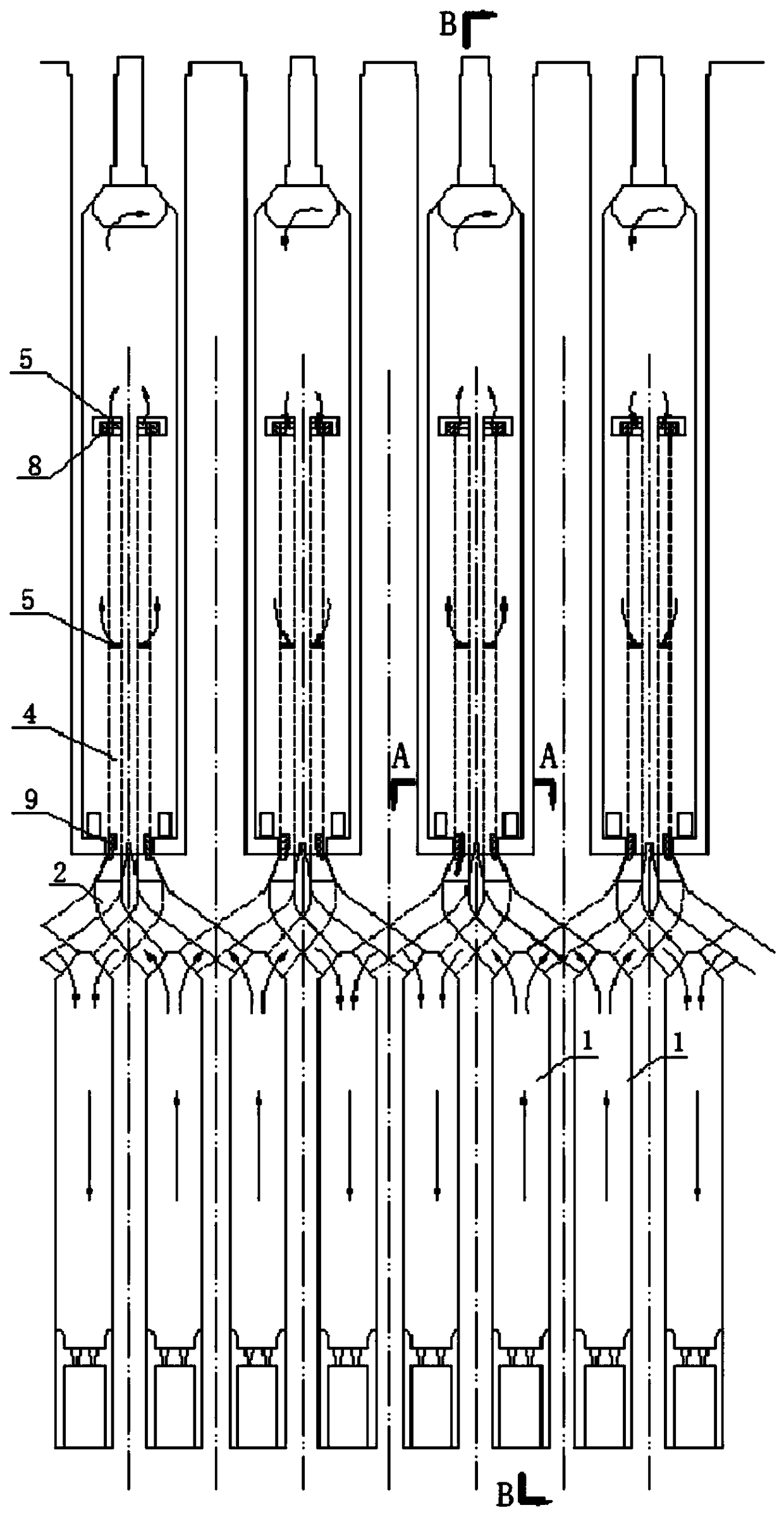

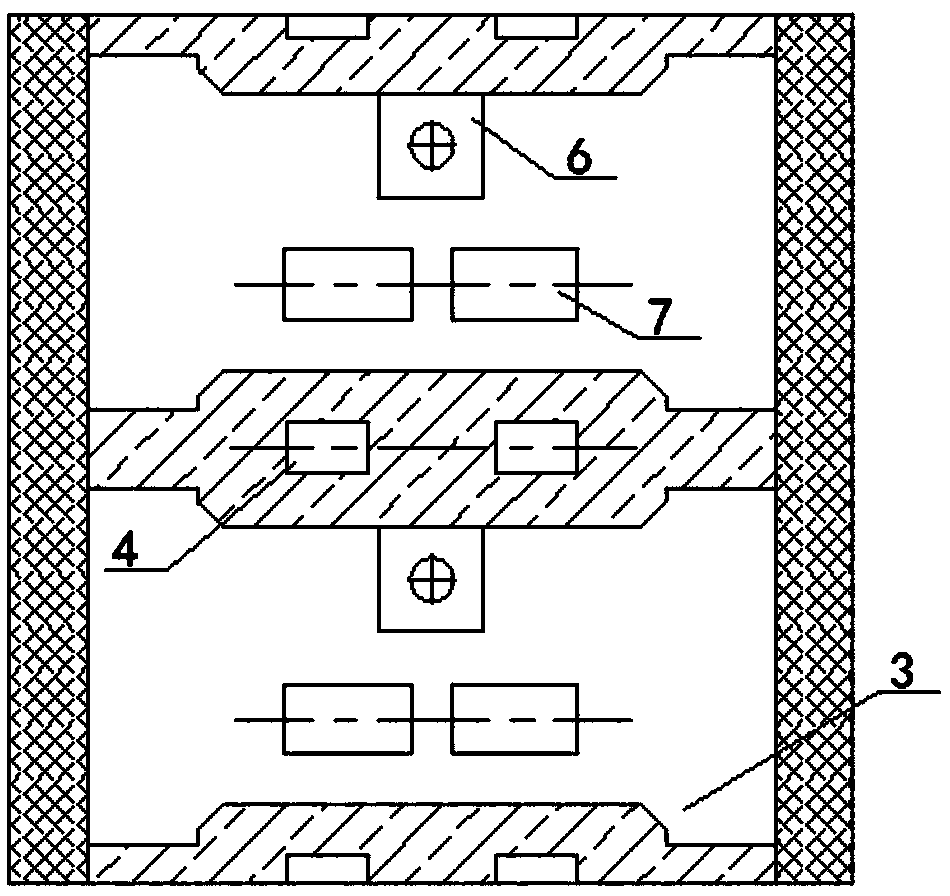

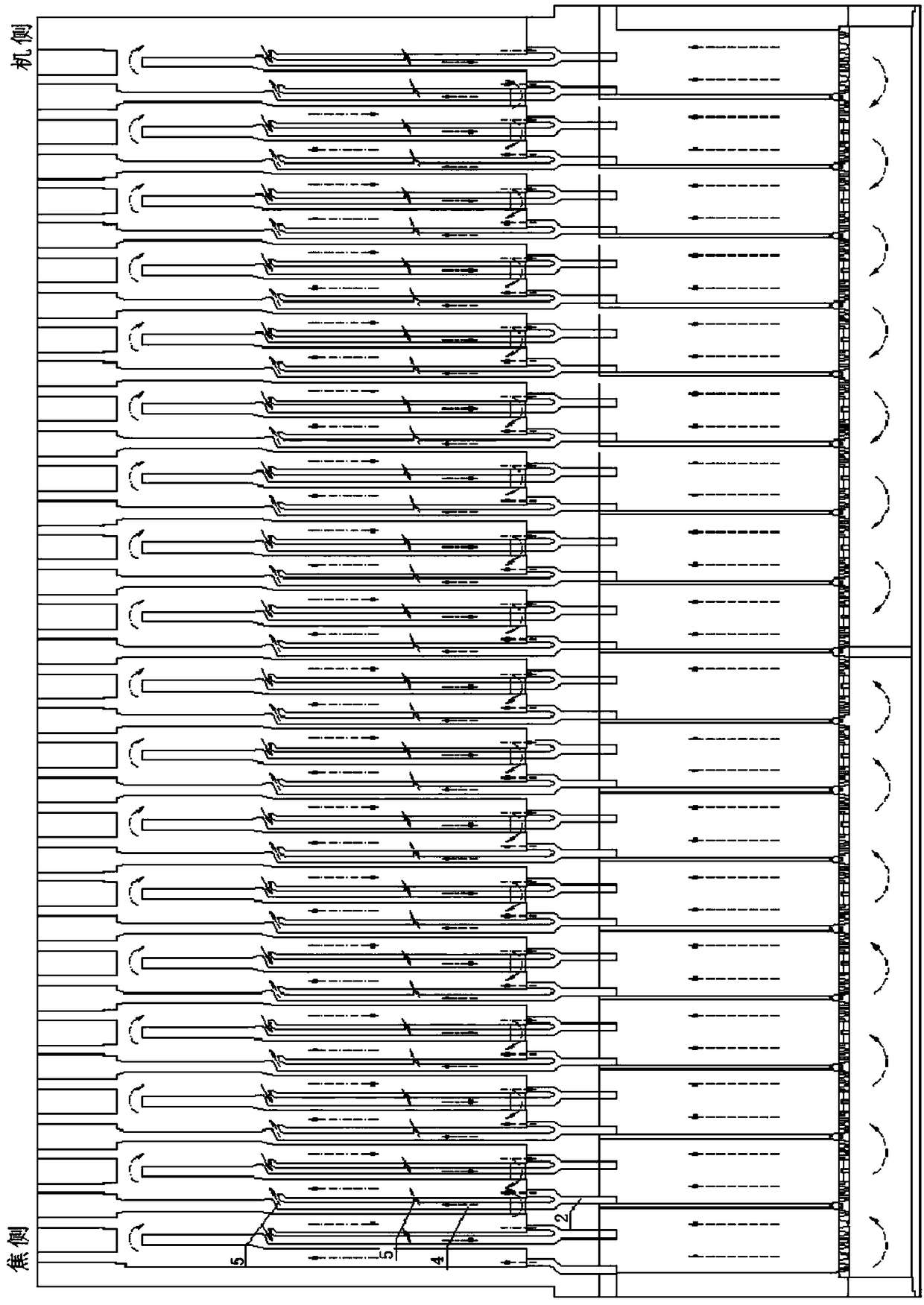

[0026] See Figure 4-Figure 7 As shown, the low-nitrogen emission coke oven heating system using rich gas heating in the present invention includes a small flue 20, a heat exchange channel, a combustion-supporting gas channel and a combustion chamber connected sequentially from bottom to top, and the heat exchange channel consists of a vertical The air supply heat exchange channel 10 at the bottom of the fire channel and the segmented air supply heat exchange channel 11 of the vertical fire channel; the small flue connecting pipe 21 connected to the small flue 20 corresponding to the air supply heat exchange channel 10 at the bottom of the vertical fire channel is provided with The air supply hole 16 at the bottom of the vertical fire passage is provided with an air intake flow regulating device 18 at the bottom air supply hole 16 of the vertical ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com