A kind of modified carbon fiber reinforced asphalt pavement anti-skid material and preparation method thereof

A fiber-reinforced asphalt pavement technology, applied in the field of asphalt pavement in highway engineering, can solve the problems of poor surface layer durability and the decay of anti-skid performance of asphalt pavement, improve heat resistance, enhance adhesion, improve high temperature stability and The effect of comprehensive mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

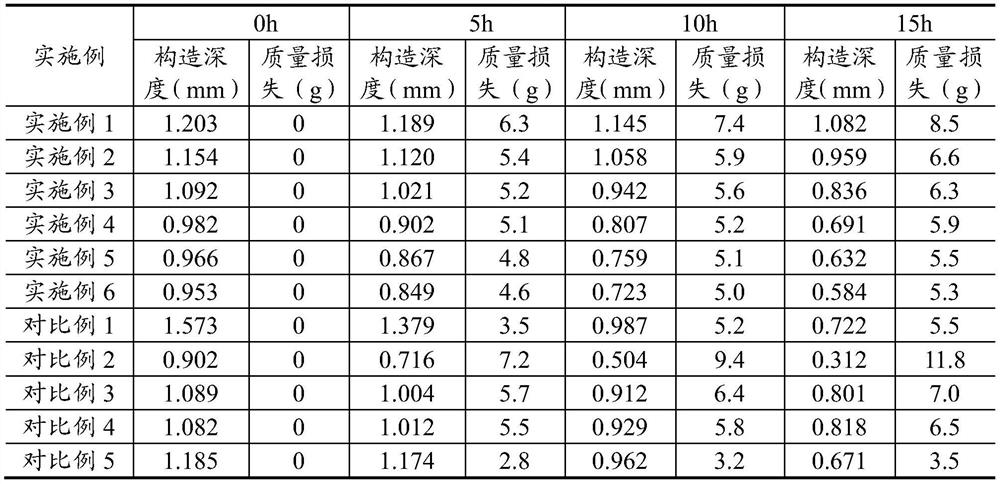

Examples

Embodiment 1

[0037] A modified carbon fiber reinforced asphalt pavement antiskid material, including the following raw materials: 42.6g of surface modified carbon fiber, 2130.7g of SBS modified asphalt epoxy binder, 213.1g of ultrafine organic montmorillonite, and 14914.8g of non-skid aggregate , anti-slip aggregate 27698.9g; among them, SBS modified asphalt epoxy binder contains 80% of SBS modified asphalt, 12% of bisphenol A epoxy resin and 8% of aliphatic polyamine; the material of non-slip aggregate It is limestone, containing 15% of 4.75-9.50mm aggregate, 22% of 2.36-4.75mm aggregate, 22% of 1.18-2.36mm aggregate, 21% of 0.60-1.18mm aggregate and 20% of 0-0.60mm aggregate; The sliding aggregate contains basalt and sintered bauxite with a mass ratio of 1:1, the basalt contains 50% of 4.75-9.50mm aggregate and 50% of 2.36-4.75mm aggregate, and the sintered bauxite contains 50% of 4.75-9.50mm aggregate % and 2.36 ~ 4.75mm aggregate 50%.

[0038] The preparation method of the above-menti...

Embodiment 2

[0045] A modified carbon fiber reinforced asphalt pavement anti-skid material, including the following raw materials: surface modified carbon fiber 42.1g, SBS modified asphalt epoxy binder 2189.0g, ultrafine organic montmorillonite 252.6g, non-skid aggregate 15996.3g , Anti-skid aggregate 26520.1g; Among them, SBS modified asphalt epoxy binder contains 80% of SBS modified asphalt, 12% of bisphenol A epoxy resin and 8% of aliphatic polyamine; the material of non-skid aggregate It is limestone, containing 13% of 4.75-9.50mm aggregate, 20% of 2.36-4.75mm aggregate, 21% of 1.18-2.36mm aggregate, 24% of 0.60-1.18mm aggregate and 22% of 0-0.60mm aggregate; The sliding aggregate contains basalt and sintered bauxite with a mass ratio of 1:1, the basalt contains 50% of 4.75-9.50mm aggregate and 50% of 2.36-4.75mm aggregate, and the sintered bauxite contains 50% of 4.75-9.50mm aggregate % and 2.36 ~ 4.75mm aggregate 50%.

[0046] The preparation method of the above-mentioned modified c...

Embodiment 3

[0053] A modified carbon fiber reinforced asphalt pavement anti-slip material, including the following raw materials: surface modified carbon fiber 84.5g, SBS modified asphalt epoxy binder 2323.9g, ultrafine organic montmorillonite 338.0g, non-slip aggregate 16901.4g , Anti-skid aggregate 25352.1g; Among them, SBS modified asphalt epoxy binder contains 80% of SBS modified asphalt, 12% of bisphenol A epoxy resin and 8% of aliphatic polyamine; the material of non-skid aggregate It is limestone, containing 14% of 4.75-9.50mm aggregate, 21% of 2.36-4.75mm aggregate, 20% of 1.18-2.36mm aggregate, 22% of 0.60-1.18mm aggregate and 23% of 0-0.60mm aggregate; The sliding aggregate contains basalt and sintered bauxite with a mass ratio of 1:1, the basalt contains 50% of 4.75-9.50mm aggregate and 50% of 2.36-4.75mm aggregate, and the sintered bauxite contains 50% of 4.75-9.50mm aggregate % and 2.36 ~ 4.75mm aggregate 50%.

[0054] The preparation method of the above-mentioned modified c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com