Food bagging device

A bagging device and food technology, which is applied in packaging and other fields, can solve the problems of rising labor costs, low efficiency, matching, etc., and achieve the effect of high automation and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

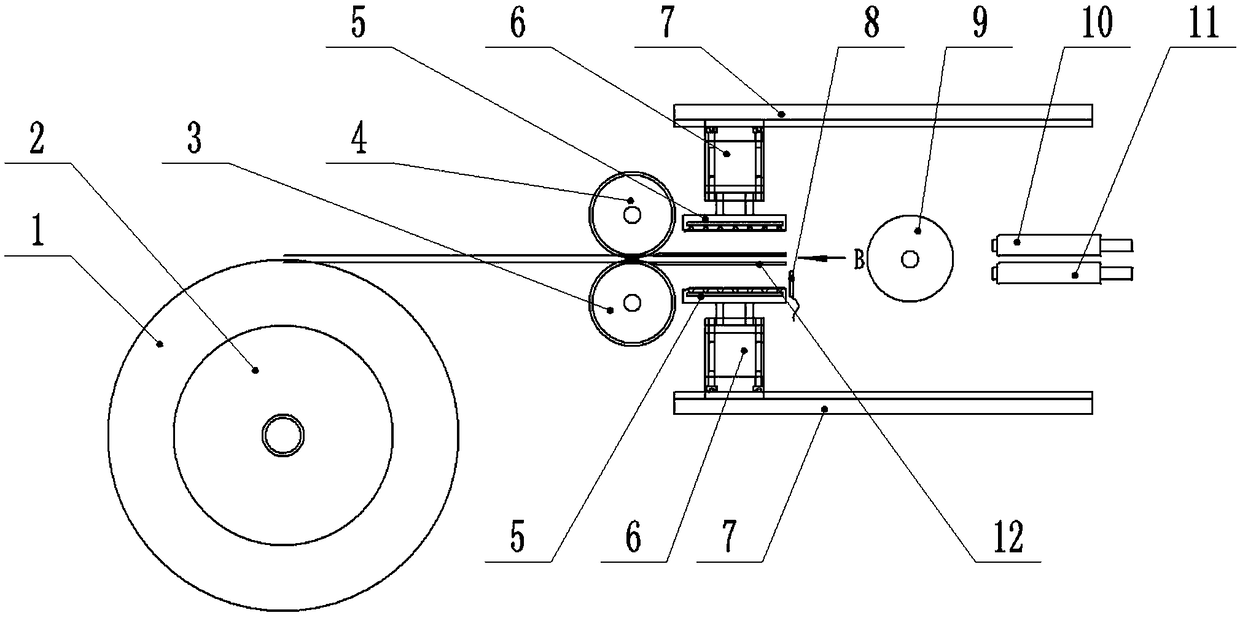

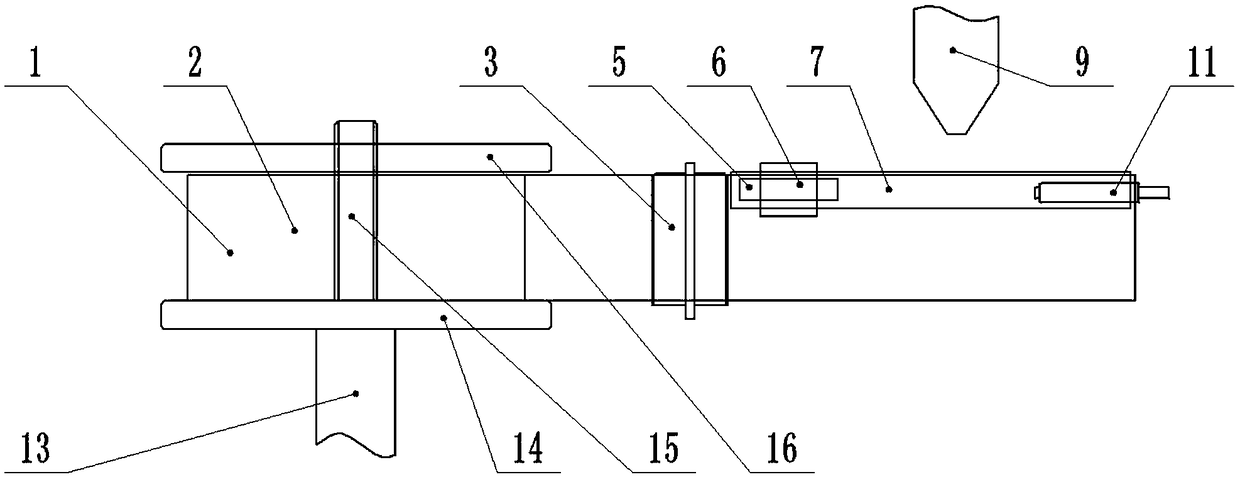

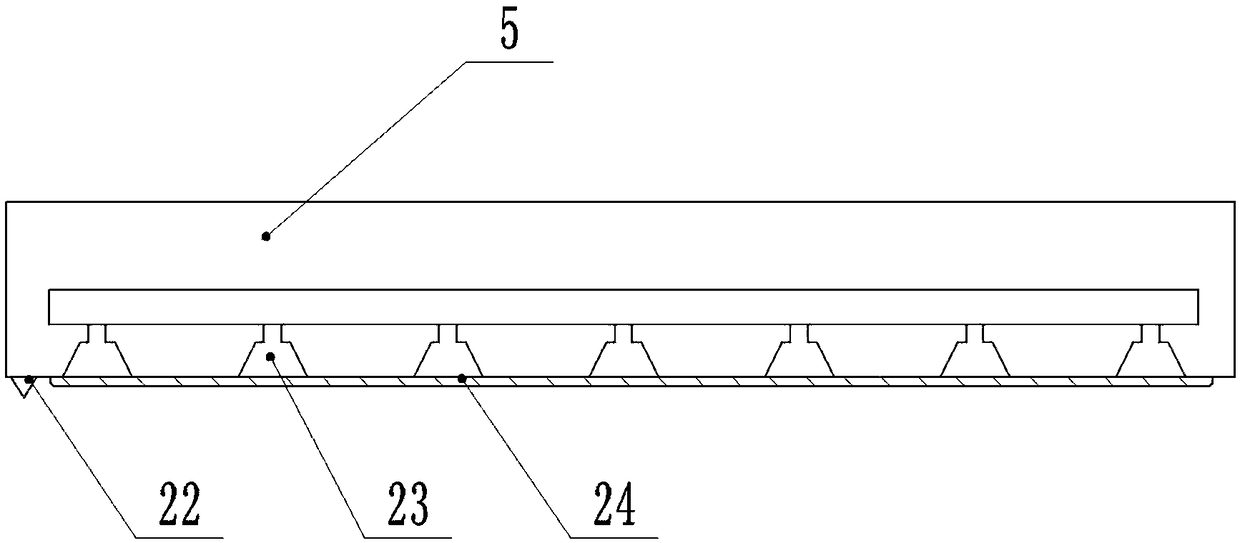

[0038] Such as figure 1 , 2 As shown, a food bagging device according to the embodiment of the present invention includes: a conveying driving wheel 3 and a conveying driven wheel 4, which are vertically installed without gaps between the conveying driving wheel 3 and the conveying driven wheel 4, and the conveying driving wheel 3 and the frictional force between the conveying driven wheel 4, the nylon bag is conveyed to the suction cup frame place on the right. The turntable mechanism 1 is located on the left side of the conveying driving wheel 3 and the conveying driven wheel 4, and the rolled nylon bag 2 is installed on the rotating disk mechanism 1; the slide rail 12 is installed at the right exit of the conveying driving wheel 3 and the conveying driven wheel 4; The frame 5 is installed under the slide rail 12, the back of the suction cup frame 5 is connected to the cylinder 6, and the cylinder 6 is installed on the linear guide rail 7 through bolts, and the action of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com