Excessive flash removing device and technology of MIM (Metal Injection Molding) green body

A kind of equipment and green body technology, which is applied in the field of removing MIM green body, can solve the problems of difficult to guarantee yield rate, low production efficiency, over-repair, etc., achieve simple and stable processing operation, improve production efficiency, and reduce production cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

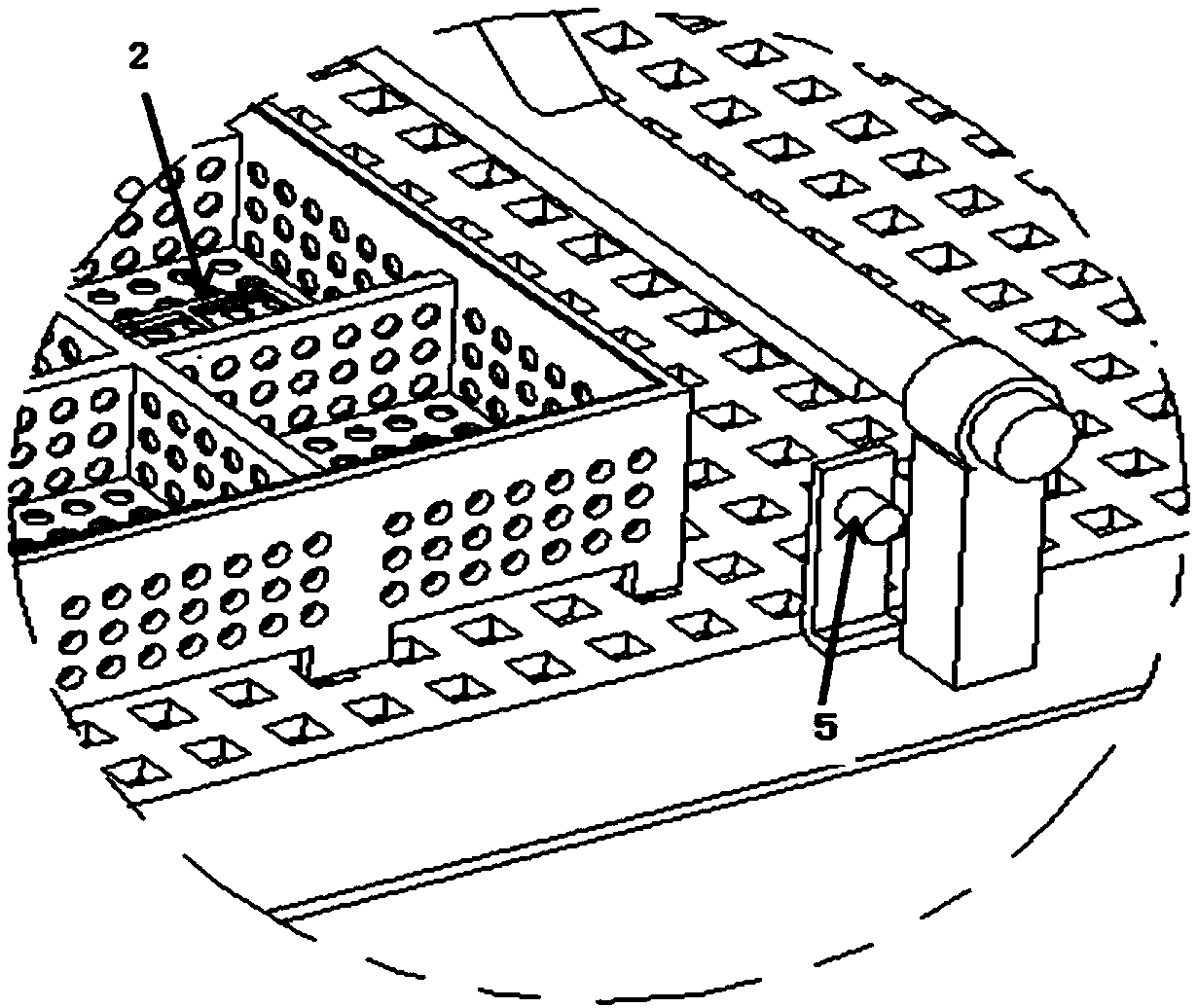

Image

Examples

example 1

[0050] Process 1000 pieces of mobile phone card holder MIM blanks with a length and width of 35*20mm and a thickness of 1mm according to the above-mentioned method; the processing parameters are: dry running speed 2m / s, processing speed 1m / mim, dry ice flow rate 0.4kg / min, injection pressure 7bar.

[0051] According to this example, the first pass rate of the product obtained is 98%.

example 2

[0053] Process 1,000 pieces of mobile phone card holder MIM blanks with a length and width of 35*20mm and a thickness of 1mm according to the above-mentioned method; the processing parameters are: dry running speed of 2m / s, processing speed of 0.8m / mim, dry ice flow rate of 0.3 kg / min, injection pressure 8bar.

[0054] According to this example, the first pass rate of the product is 98.9%.

example 3

[0056] Process 800 pieces of watch case MIM blanks with a length and width of 55*45mm and a thickness of 10mm according to the above-mentioned method; the processing parameters are: dry running speed 2m / s, processing speed 0.6m / mim, dry ice flow rate 0.2 kg / min, injection pressure 4bar.

[0057] According to this example, the first pass rate of the product is 97%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com