Method for stably repairing heavy metal contaminated soil by using sludge base charcoal ash

A technology for polluting soil and heavy metals, applied in the restoration of polluted soil, etc., to achieve significant and long-lasting passivation effects, wide sources of raw materials, and broad market prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

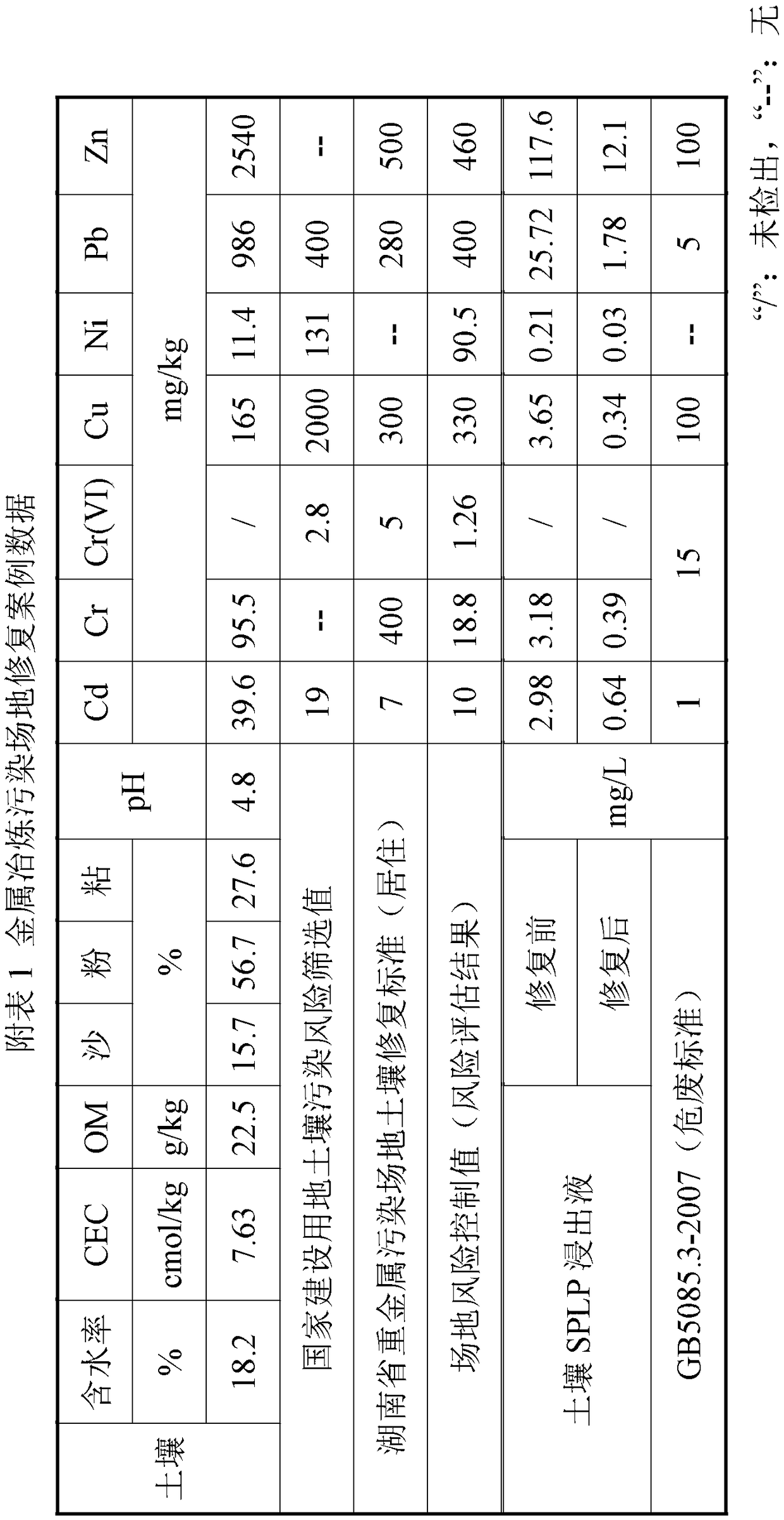

Examples

Embodiment 1

[0032] A. Preparation of sludge-based carbon ash remediation materials

[0033] The dewatered sludge is taken from a domestic sewage plant in central China, and the sewage treatment process of this plant is A 2 O, the moisture content of the dewatered sludge is 60%. The dewatered sludge was blown and dried at 105°C, and after cooling, it was crushed through a 10-mesh standard sieve to obtain sludge granules.

[0034] Part of the sludge particles were pyrolyzed in an oxygen-limited environment at 300°C for 3 hours, and the solid carbonization product was collected after cooling, which was low-temperature sludge-based biochar.

[0035] Incinerate another part of the sludge particles in an oxygen-enriched environment at 850°C for 3 hours, and collect the solid ash remaining on the grate after cooling, which is the sludge incineration ash.

[0036] Industrial-grade phosphate rock powder was purchased from a chemical company in Shandong. The main component is fluoro-apatite, cont...

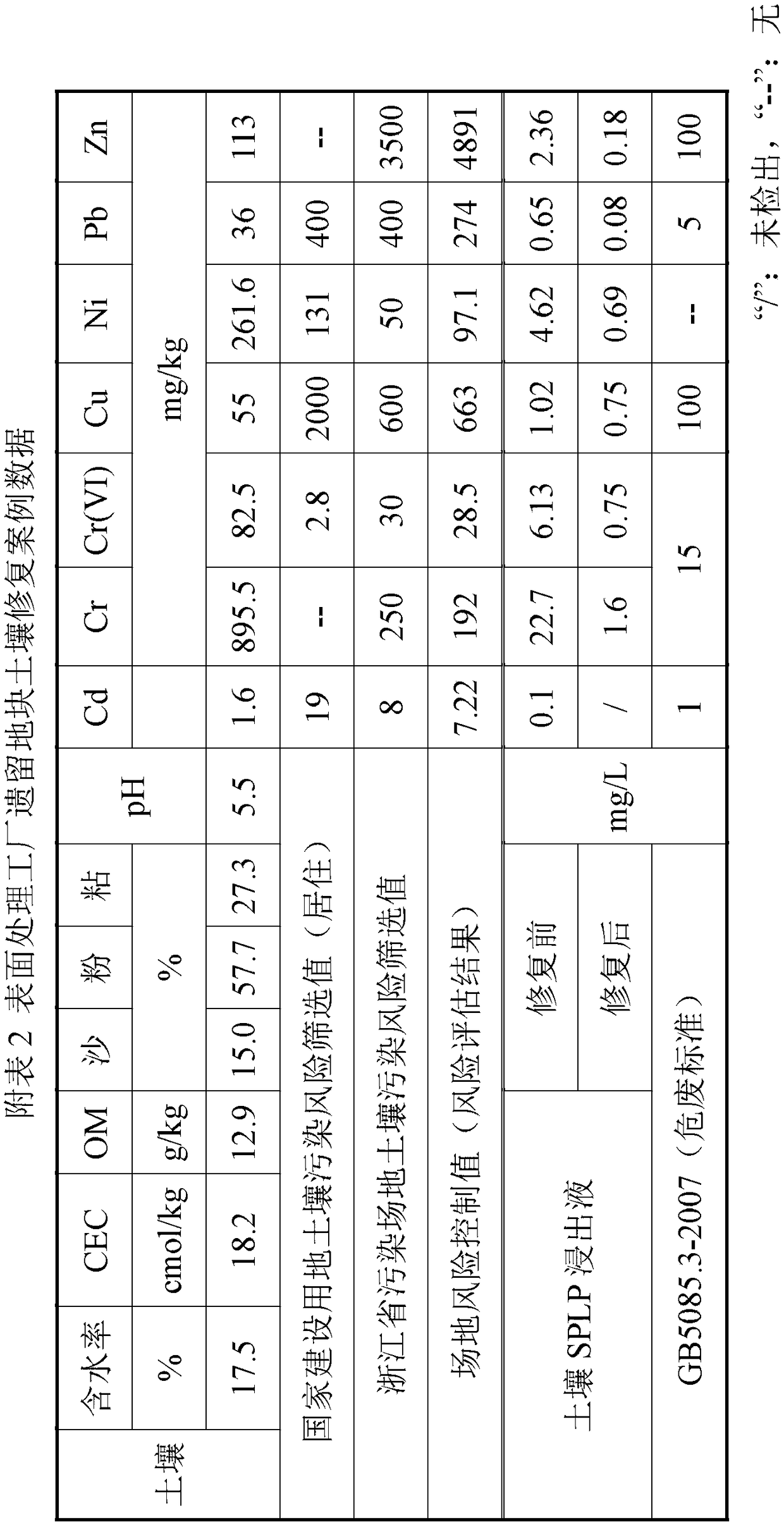

Embodiment 2

[0041] A. Preparation of sludge-based carbon ash remediation materials

[0042] The dewatered sludge is taken from an urban domestic sewage plant in East China, and the sewage treatment process of this plant is A 2 O, the moisture content of the dewatered sludge is 62%. The dewatered sludge was blown and dried at 110°C, and after cooling, it was crushed through a 10-mesh standard sieve to obtain sludge granules.

[0043] Part of the sludge particles were pyrolyzed in an oxygen-limited environment at 350°C for 2 hours, and the solid carbonization product was collected after cooling, which was low-temperature sludge-based biochar.

[0044] The other part of the sludge particles was incinerated in an oxygen-enriched environment at 900°C for 2 hours, and after cooling, the solid ash remaining on the grate was collected, which was the sludge incineration ash.

[0045] Industrial-grade phosphate rock powder was purchased from a chemical company in Shandong. The main component is f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com