Environment-friendly intelligent grain flat extruding and impurity removing equipment

A food and environmental protection technology, applied in lighting and heating equipment, food science, grain pod removal, etc., can solve the problems of inconvenient metal extraction, low intelligence, waste, etc., to prevent heat from spreading outward and improve intelligence. The degree of chemical change and the effect of improving the heating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0038] as attached figure 1 To attach Figure 7 shown

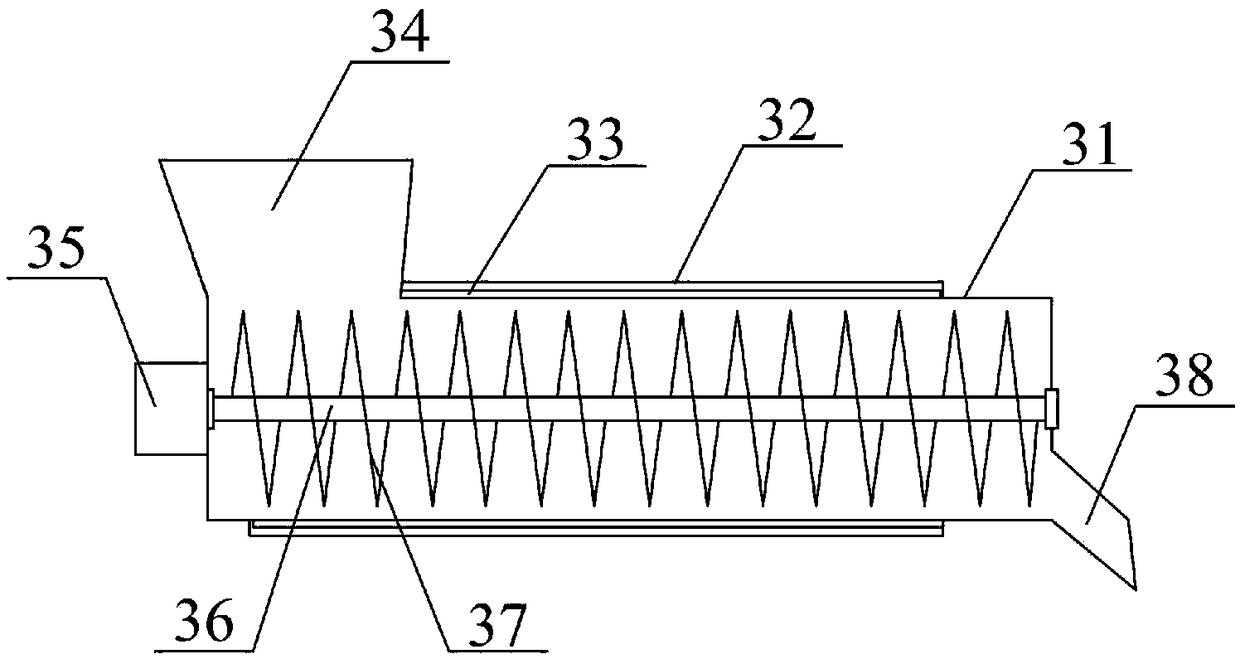

[0039] The invention provides an environment-friendly and intelligent grain extrusion and removal equipment, which includes a screw feeder 1, a heating cylinder mounting frame 2, an auxiliary heating and conveying device for cereal grains 3, a peeling feed hopper 4, a peeling box 5, a Leather cylinder 6, rotating motor 7, peeling rubber pad 8, adjustable material guide frame structure 9, support frame 10, fixed cross bar 11, grain vibration separation frame structure 12, installation shell 13, touch screen 14, controller 15, Cereal grain waste residue collection device 16, waste residue crushing utilization device 17, flattening hopper 18, protective frame 19, triangular guide block 20, conveying platform 21 and electric roller 22, the screw feeder 1 is installed on the cereal grain auxiliary heating The lower left part of the conveying device 3; the heating cylinder installation frame 2 is welded on the upper left side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com