Preparation process of ropivacaine mesoporous-bioactive-glass composite microspheres

A technology of bioactive glass and composite microspheres, which can be used in drug combinations, organic active ingredients, microcapsules, etc., and can solve problems such as lack of research.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

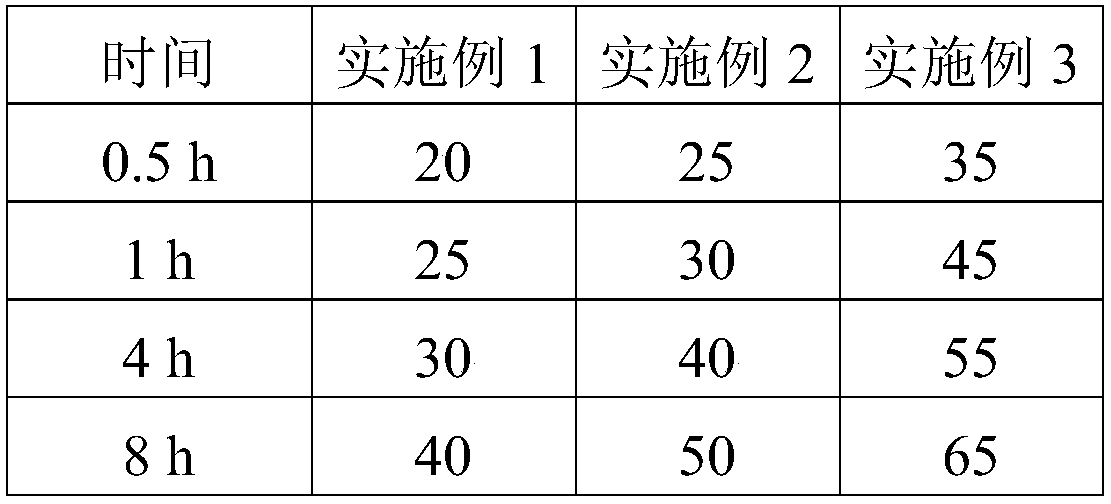

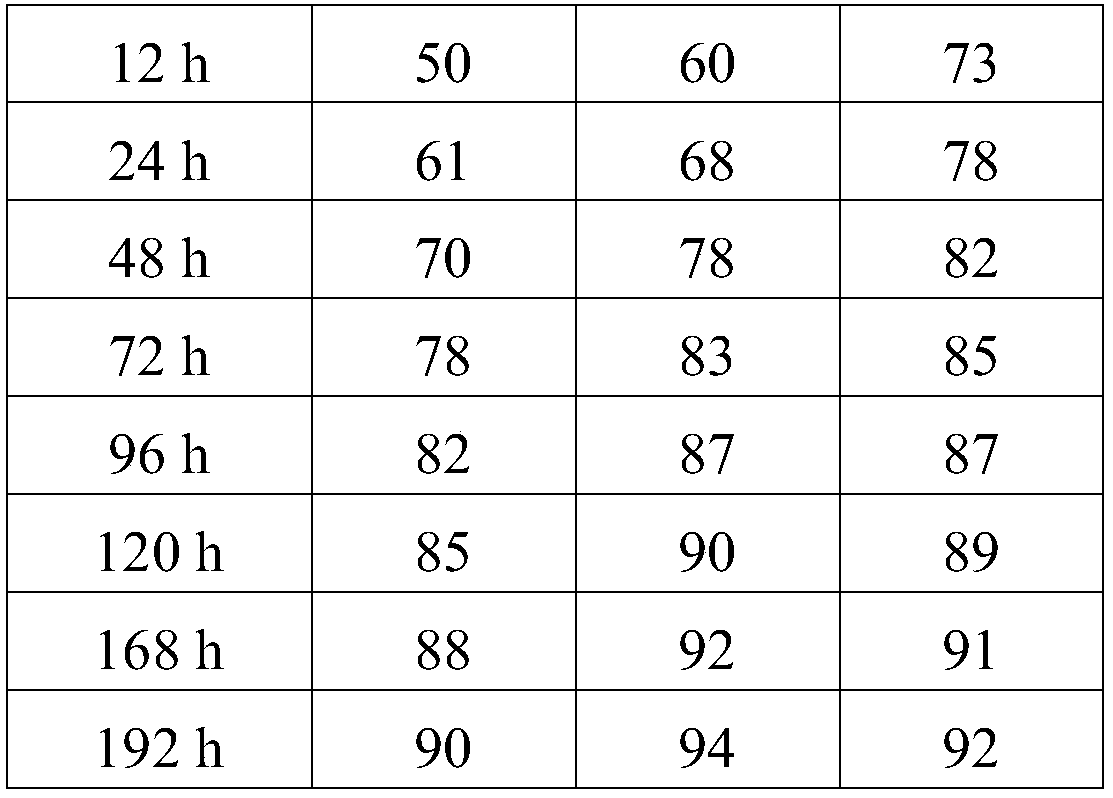

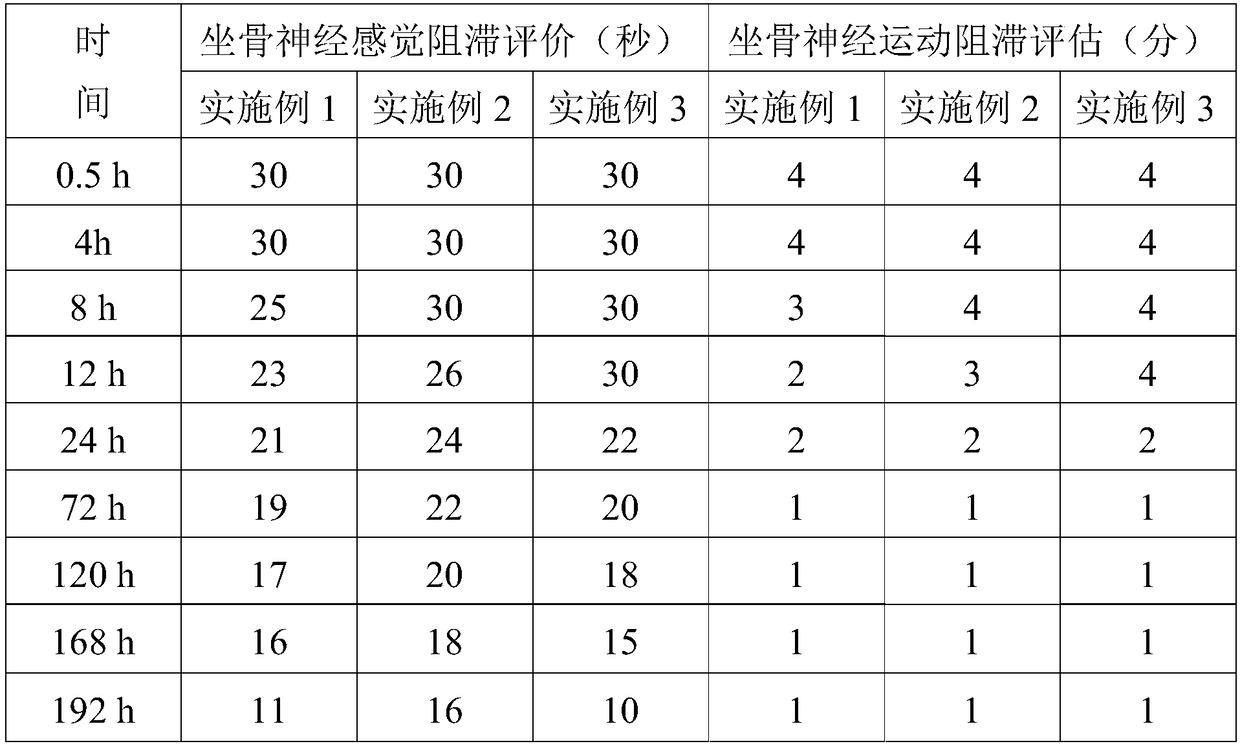

Embodiment 1

[0032] Example 1: The specific preparation method of the ropivacaine mesoporous bioactive glass composite microspheres provided in this example is as follows:

[0033] Step 1: SiO 2 Preparation of colloidal crystal templates

[0034] Monodisperse SiO 2 Preparation of Microspheres: Using A method for the preparation of monodisperse SiO by an alkaline hydrolysis process of ethyl orthosilicate (TEOS) 2 microsphere suspension. Weigh 251.2g absolute ethanol, 118.25g deionized water and 34g NH 3 ·H 2 O was placed in an Erlenmeyer flask, and after mixing evenly under magnetic stirring, 27.7g TEOS was added, and magnetic stirring was continued for 3h to obtain SiO 2 Suspension of particles.

[0035] SiO 2 Preparation of colloidal crystal template: firstly, the SiO prepared above 2 The suspension of particles was rotovaped to remove excess solvent, which was then placed in a flat-bottomed vessel and centrifuged to remove excess solvent, resulting in large, disordered SiO 2 c...

Embodiment 2

[0044] Example 2: The preparation method is the same as in Example 1, except that in step 5, the PEG with a molecular weight of 6,000 is replaced with PEG with a molecular weight of 10,000, and the pressurized plane is made of glass. The pressurized pressure was 0.054 MPa.

Embodiment 3

[0045] Example 3: The preparation method is the same as that of Example 1, except that in step 5, the PEG with a molecular weight of 6,000 is replaced with PEG with a molecular weight of 20,000, and ceramics are used for the pressing plane. The pressurized pressure is 0.08 MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| Mohs hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com